A complete set of intelligent fire baking paper drying equipment

A complete set of equipment and fire-baked paper technology, which is applied in the direction of dryers, papermaking, paper machines, etc., can solve problems such as low heat utilization rate, bad indoor environment, and fires in finished paper, so as to change the working environment and eliminate direct hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

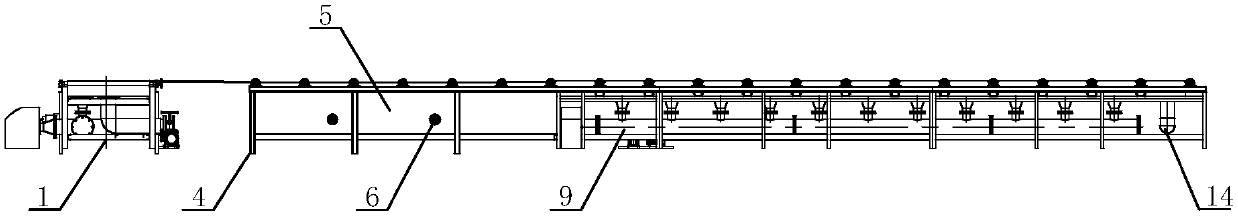

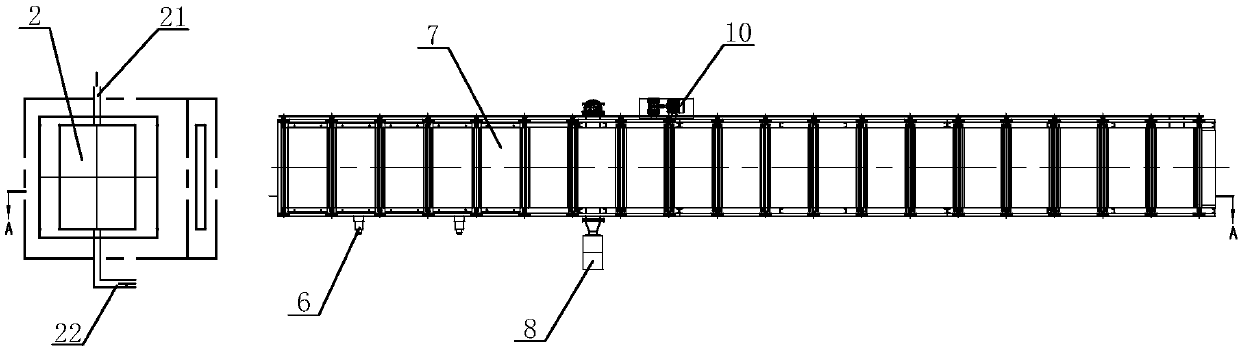

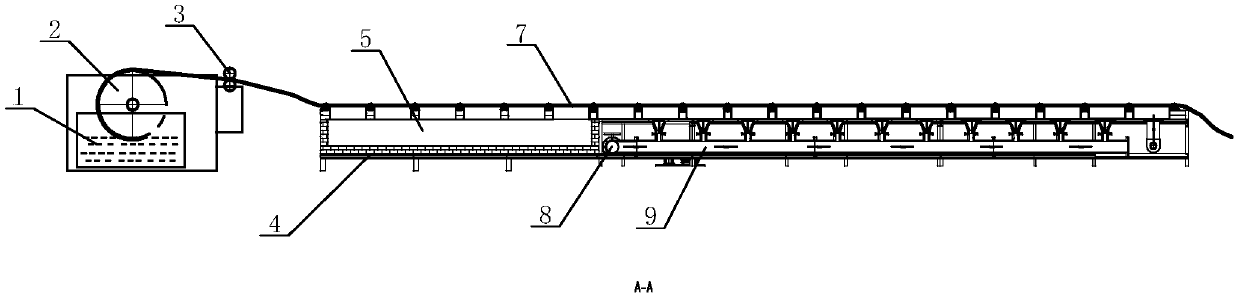

[0020] like Figure 1-8 As shown: a complete set of intelligent fire-baking paper drying equipment of the present invention, which includes a pulp tank 1, a forming drum 2, a rolling drum 3, a combined frame 4, a furnace 5, a burner 6, a heat storage combined oven 7, a micro Gas turbine 8, main pipeline system 9, transmission device 10, throttling device 11, variable diameter connecting pipe 12, heat storage tail box 13, tail box exhaust pipe 14, temperature sensor 15 and control box 16, the molding The drum 2 is set in the pulp tank 1, a pair of the rolling cylinders 3 are set on the side of the forming drum 2, the combined frame 4 is set on the side of the pulp tank 1, and several of the heat storage The combination oven 7 is arranged on the upper end of the combination frame 4, and the transmission device 10 is arranged on one side of the combination frame 4, and the combination frame 4 is composed of a group of six-meter frames 41 and two groups of four-meter frames 42 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com