Method for preparing paper-based material by bleaching KP pulp through biochemical method ECF of fast-growing poplars

A biochemical, fast-growing poplar technology, applied in the field of papermaking, can solve the problems of sizing thickness, stiffness and strength reduction, safety hazards, paper is not easy to degrade, and the decline is large, so as to avoid poor control of beating conditions and easy degradation of strength , The effect of reducing the requirement of beating degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

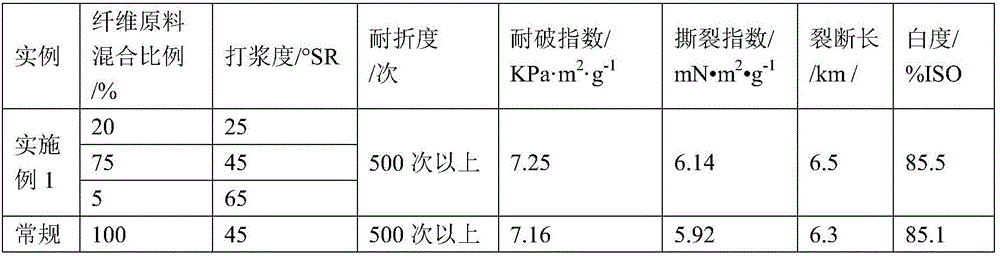

[0040]Example 1 A method for preparing paper-based materials from fast-growing poplar biochemical method ECF bleaching KP pulp, this embodiment prepares environmentally friendly packaging paper-based materials.

[0041] Proceed as follows:

[0042] (1) High-performance element-free chlorine-free fast-growing poplar bleached chemical pulp obtained by patent ZL201310300563.8 "a fast-growing poplar KP pulp biochemical method ECF bleaching process", the pulp whiteness is 86.1% ISO, three parts of pulp are taken The PFI mill is used for precise refining, so that the beating degrees of the pulp are 25°SR, 45°SR, and 65°SR respectively.

[0043] Wherein, the concrete preparation method of the paper pulp that brightness is 86.1%ISO is as follows:

[0044] 1) Cooking: take the fast-growing poplar wood chips with a length of 15-25mm, a width of 10-20mm, and a thickness of 3-5mm, and after natural air-drying, carry out cooking to obtain the raw pulp of fast-growing poplar sulfate. The c...

Embodiment 2

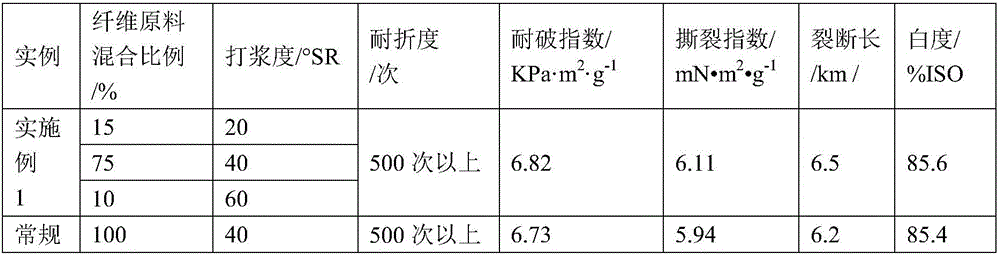

[0054] Example 2 A method for preparing paper-based materials from fast-growing poplar biochemical method ECF bleaching KP pulp, this embodiment prepares environmentally friendly packaging paper-based materials.

[0055] Proceed as follows:

[0056] (1) Using the pulp prepared in Example 1 as a raw material, three parts of the pulp were refined using a PFI mill so that the beating degrees of the pulp were 20°SR, 40°SR, and 60°SR respectively.

[0057] (2) Pulp fiber raw materials that have been beaten or refined and prepared according to the pulp fiber raw material mixing ratio of 15:75:10 (mass ratio) with a beating degree of 20 ° SR, 40 ° SR, and 60 ° SR are decomposed by a fiber decomposer. It is homogeneously mixed and then pressed on a sheet former at 130 g / m 2 Eco-friendly packaging paper-based material.

[0058] (3) At the same time, select 100% pulp fiber raw material with a beating degree of 40 ° SR, decompose it through a fiber decomposer to make it evenly mixed, a...

Embodiment 3

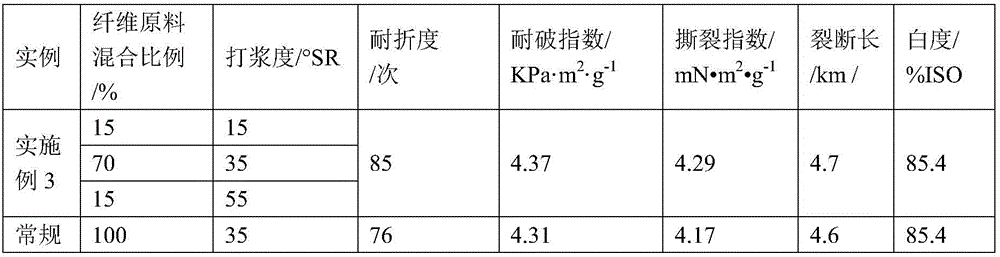

[0063] Example 3 A method for preparing paper-based materials from fast-growing poplar biochemical method ECF bleached KP pulp, this embodiment prepares household paper-based materials.

[0064] Proceed as follows:

[0065] (1) Using the pulp prepared in Example 1 as a raw material, three parts of the pulp were finely refined by a PFI mill, so that the beating degrees of the pulp were 15°SR, 35°SR, and 55°SR respectively.

[0066] (2) Pulp fiber raw materials that have been beaten or refined and prepared according to the pulp fiber raw material mixing ratio of 15:70:15 (mass ratio) with a beating degree of 15 ° SR, 35 ° SR, and 55 ° SR are decomposed by a fiber decomposer. It is homogeneously mixed and then pressed on a sheet former at 30 g / m 2 Paper-based materials for household use.

[0067] (3) At the same time, select 100% pulp fiber raw material with a beating degree of 35 ° SR, decompose it through a fiber decomposer to make it evenly mixed, and then press and form 30g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com