Compound bucket foundation with skirtboard and construction method thereof

A cylindrical foundation and composite technology, which is applied in basic structure engineering, construction and other directions, can solve the problems of limited ability to resist seabed scouring and high cost, and achieve the effect of reducing the height of soil plugs, lowering the cost and improving the penetration force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

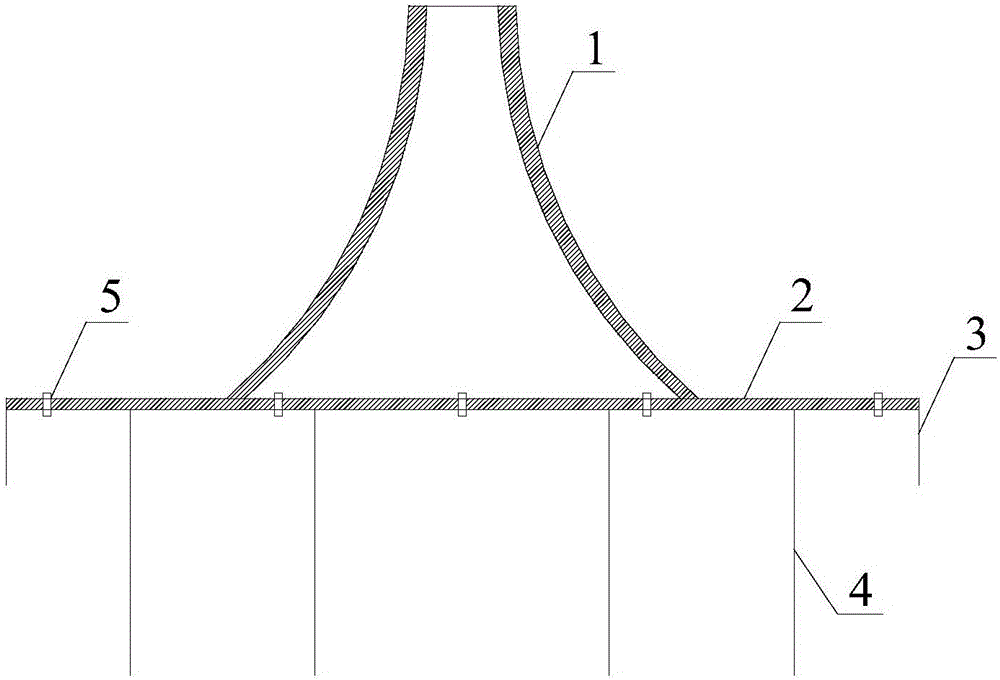

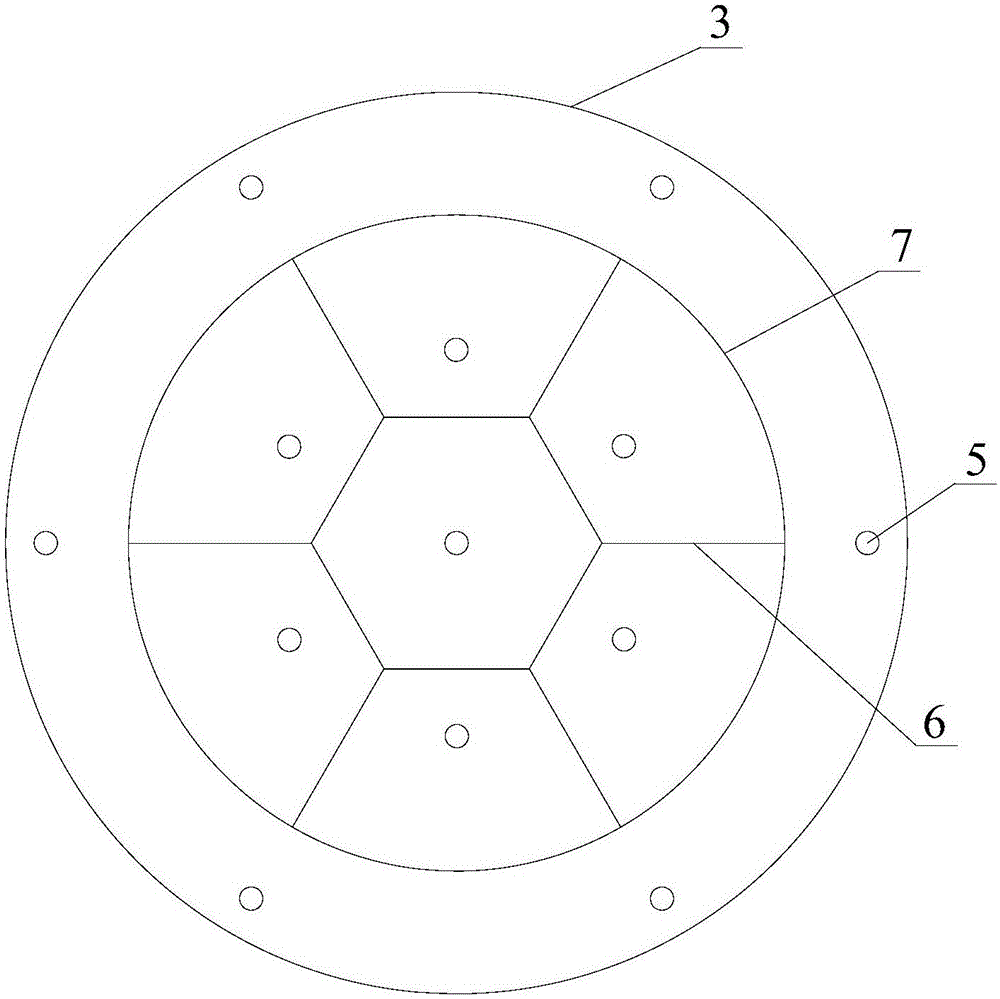

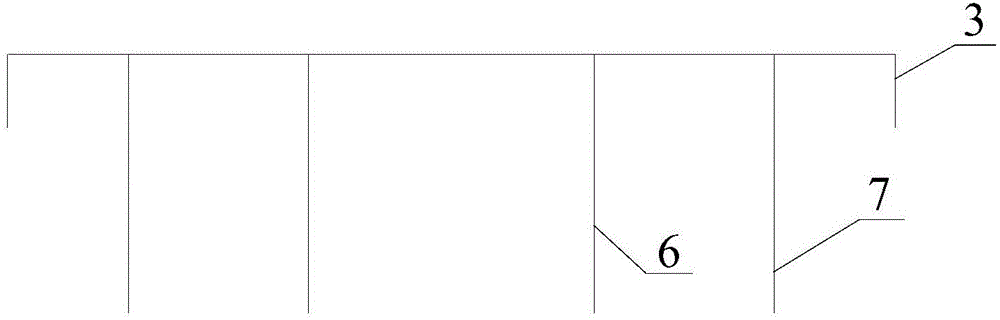

[0033] Such as Figure 1 to Figure 3 As shown, this embodiment provides a composite tubular foundation with apron, which is mainly composed of reinforced concrete transition section 1, reinforced concrete roof 2, and steel tubular structure 4.

[0034] The steel cylindrical structure 4 has a diameter of 10-50m and a wall thickness of 10-100mm. The outer edge of the top cover of the steel cylindrical structure 4 expands out of the cylindrical foundation side wall 7, and the diameter of the top cover of the steel cylindrical structure 4 is 1.2 to 2 times the diameter of the bottom annular cylinder wall. The outer edge of the top cover of the steel cylindrical structure 4 is welded with a steel skirt plate 3 extending downward from the top cove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com