A seat grout pad construction device

A technology of construction equipment and seat slurry, which is applied in the direction of infrastructure engineering and construction, can solve the problems of the number and types of instruments, high labor intensity of workers, and low construction efficiency, so as to achieve high work efficiency, low labor intensity of workers, and easy installation. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

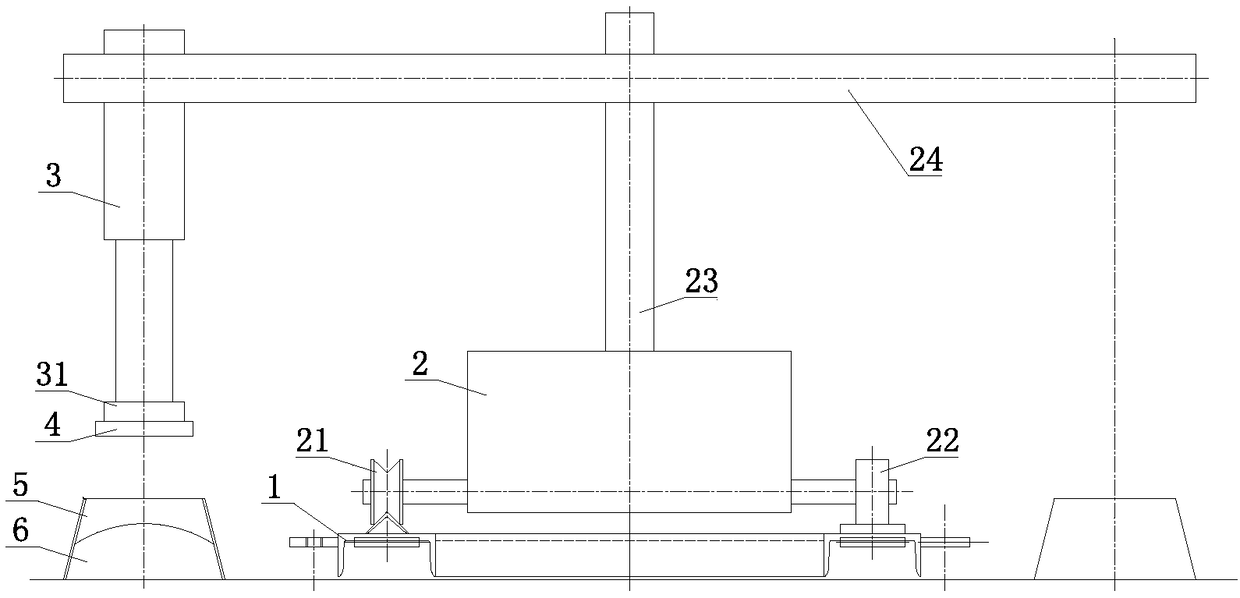

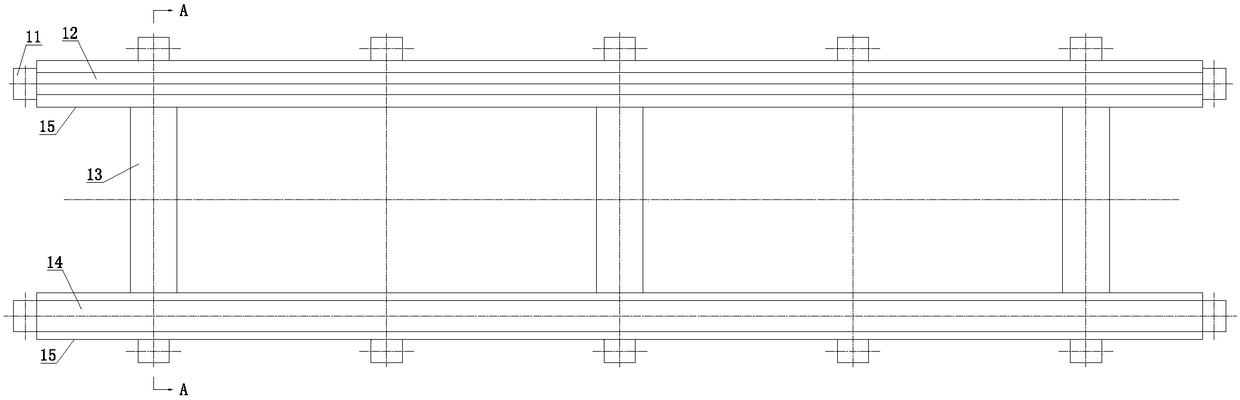

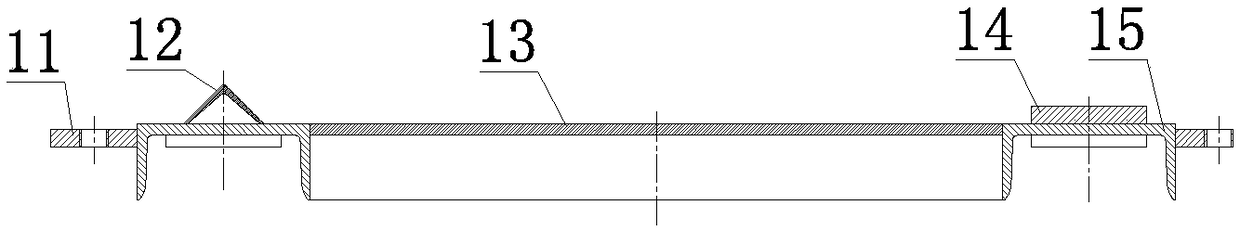

[0034] Such as Figure 1-Figure 5 As shown, a construction device for seat grout pads according to the present invention includes a base 1, a trolley 2, a vibrator 3, and a flat backing plate 4. The vibrator 3 is installed on the trolley 2, and the trolley 2 can move along the base 1 The upper guide rail (12, 14) walks; the bottom of the vibrator 3 is provided with a powerful electromagnet 31, and the electromagnet 31 is energized or powered off to absorb or loosen the flat backing plate 4, driving the flat backing plate 4 to vibrate up and down, It plays the role of slapping, so that the wet seat slurry 6 is fully fused and compacted. Since the vibrator 3 is adjusted to the same height, the lower surface of the electromagnet 31 is horizontal, and the flat backing plate 4 is also horizontal, so the levelness of the upper surface of the seat slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com