Tower body tilt correction method

A technology of tilting direction and tower body, which is applied in the field of tower tilt correction, can solve the problems of waste of manpower and material resources, poor correction effect, high cost, etc., achieve the effect of small space occupation, saving construction cost, and avoiding high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

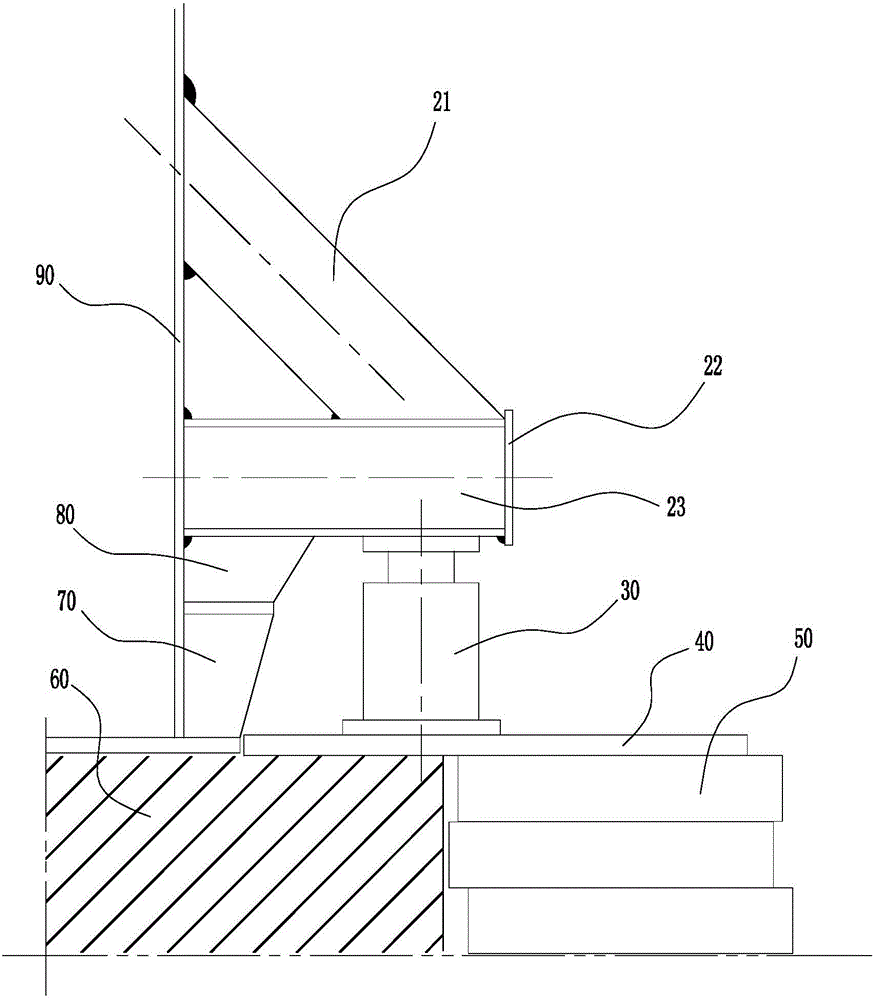

[0037] A method for correcting the inclination of the tower body of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0038] In this specific embodiment, a method for correcting the inclination of the tower body of the present invention includes the following steps:

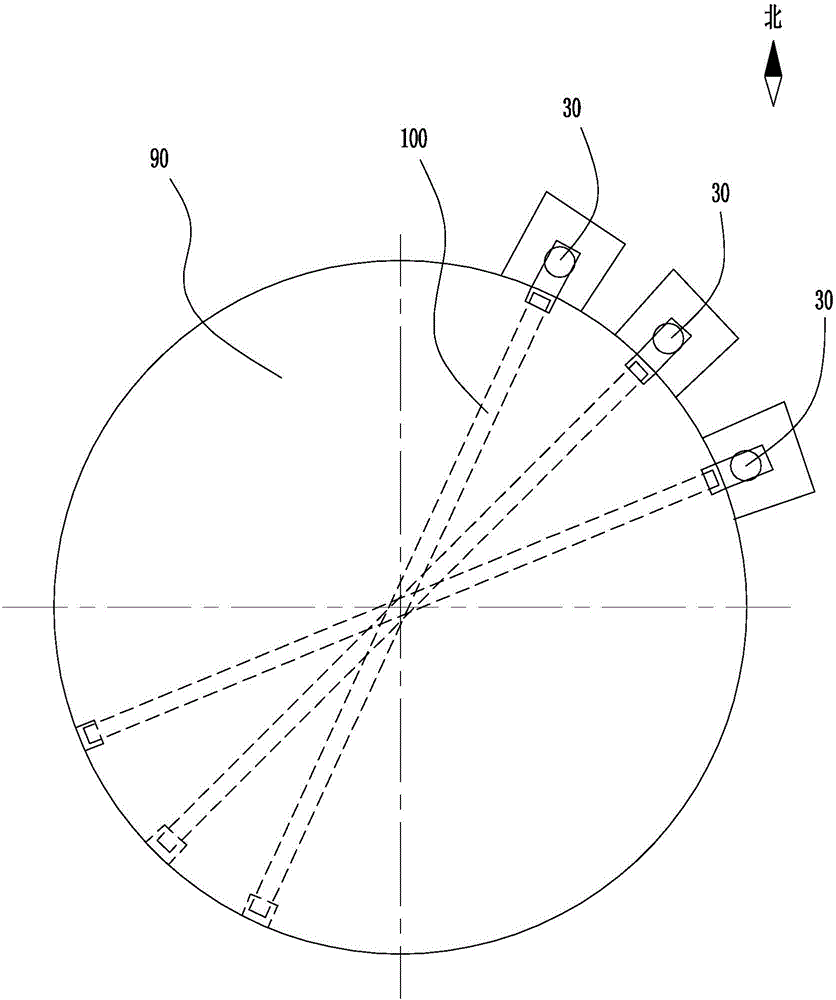

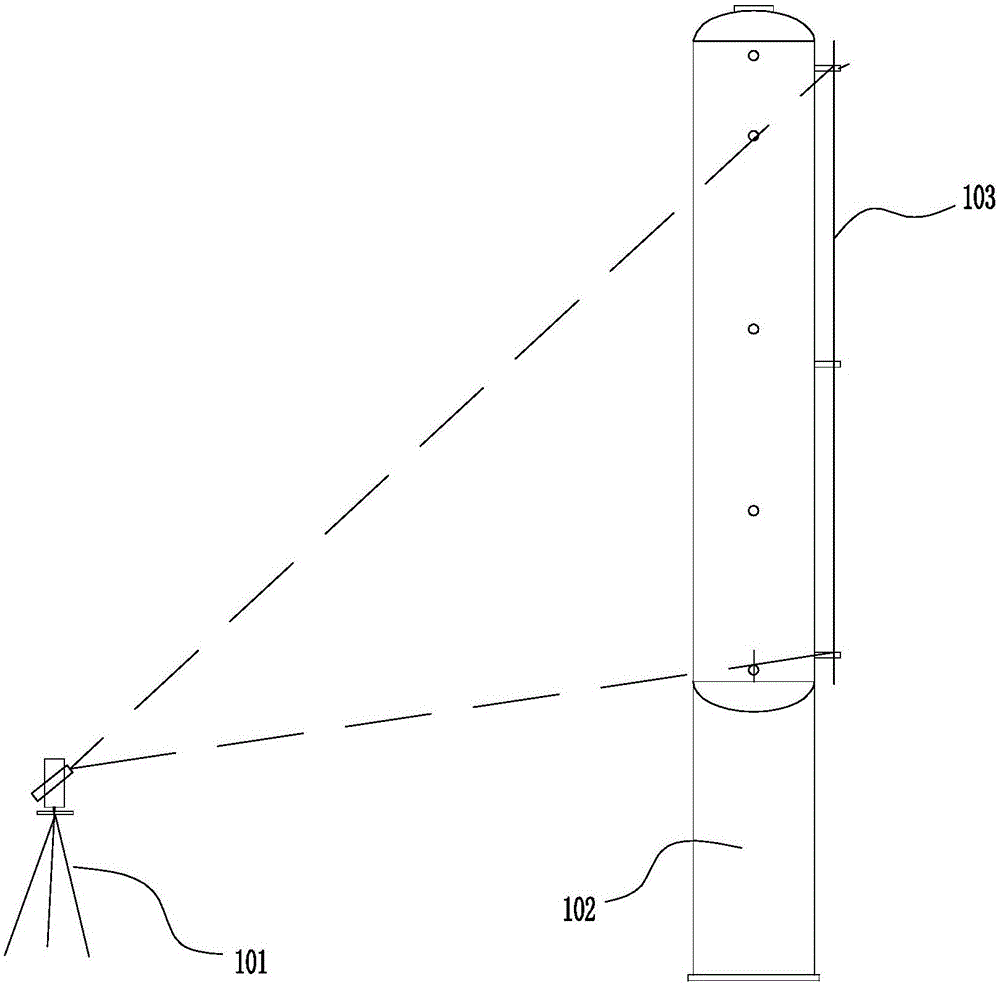

[0039] 1) Use the line pendant tool to measure the inclination azimuth and inclination range of the tower body in the tower. In order to ensure the quality of the correction work, the positions located at the upper and lower ends of the tower body are respectively selected to measure the inclination range of the tower body.

[0040] 2) Remove all scaffolding, brackets, equipment, pipes, connecting beams, grid plates, frames and platforms connected to the tower body, so that the tower body is independent and free from external forces.

[0041] 3) Break the foundation grouting layer at the bottom of the tower body.

[0042] 4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com