Constant-temperature heat tracing carbon fiber continuous sucker rod, and preparation device and preparation method thereof

A carbon fiber and sucker rod technology, used in drill pipes, drilling equipment, earthwork drilling and other directions, can solve the problems of poor torsional strength, adverse effects of sucker rod strength, poor wear resistance, etc., and achieve high tensile strength, Improve efficiency and prevent wax deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

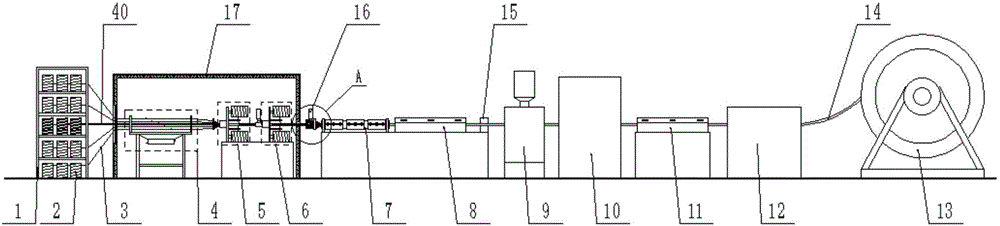

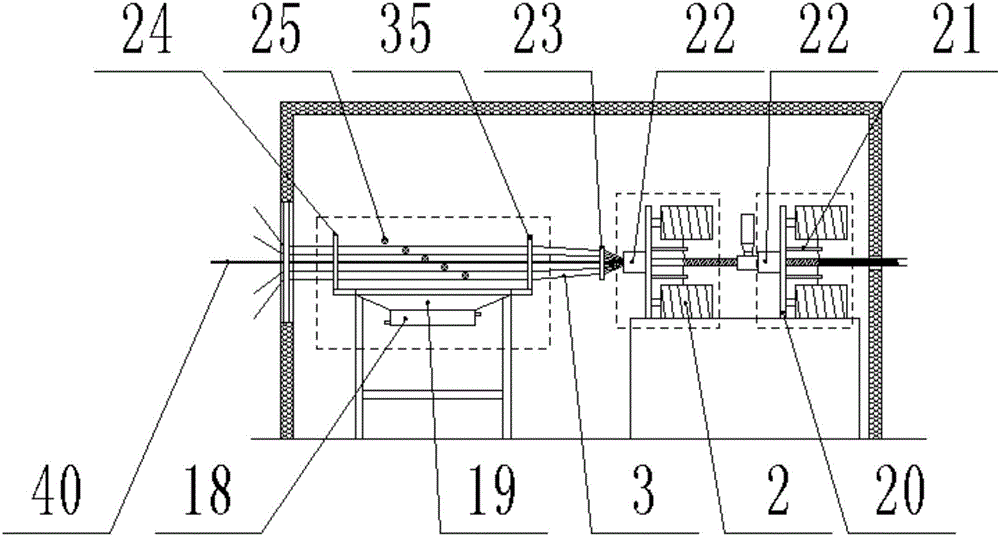

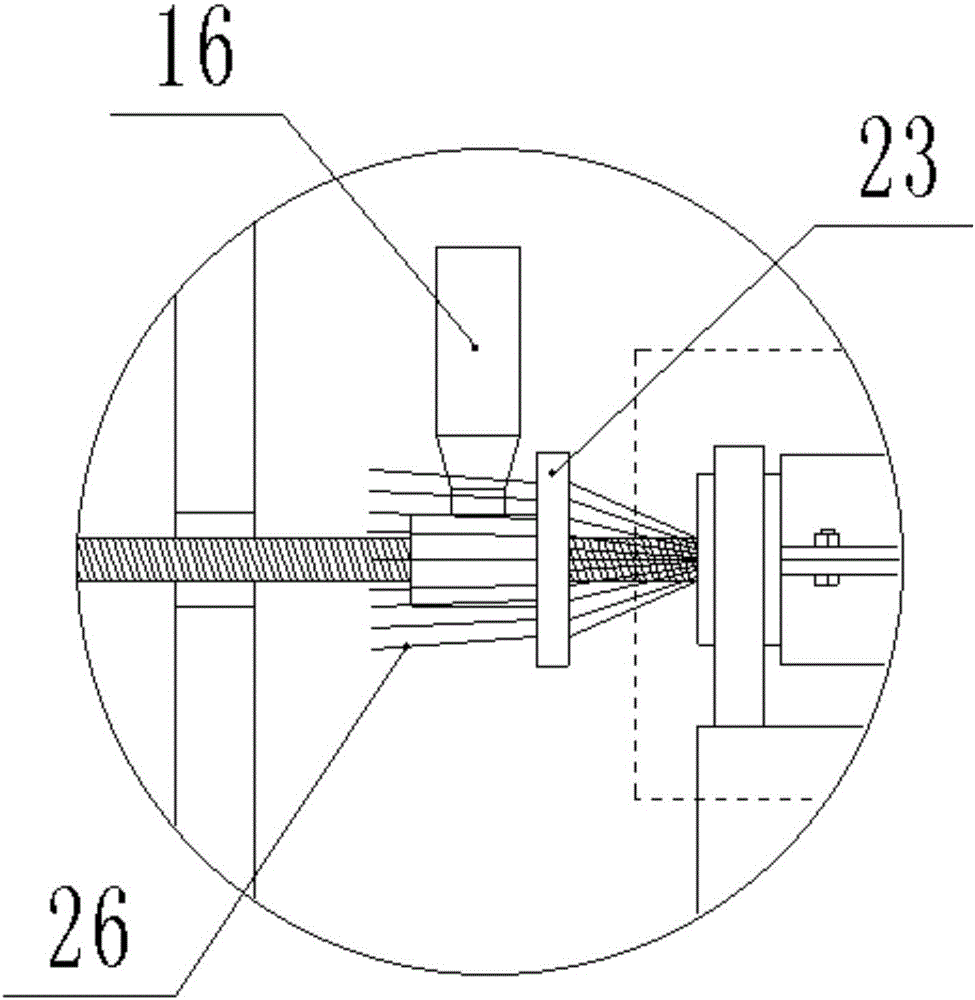

[0044] A carbon fiber continuous sucker rod with constant temperature and heat tracing includes a carbon fiber core body 28, an electric heating band A40 is arranged in the center of the carbon fiber core body 28, and the carbon fiber constituting the carbon fiber core body 28 is wrapped around the electric heating band A40. The setting of the heat tracing belt 40 can realize the constant temperature heat tracing of the sucker rod, even if the sucker rod maintains a high and stable temperature, thereby preventing the paraffin in the crude oil from condensing on the sucker rod.

[0045] The carbon fiber core 28 is composed of 150 / 12K --- 242 / 12K carbon fibers bonded by epoxy resin, and the tensile strength of the carbon fiber is ≥4950MPa. The carbon fiber core 28 is spirally wound with an electric heating belt B 45. The wound glass fiber layer A29 and the wound glass fiber layer B34, the wound glass fiber layer B34 is covered with a longitudinal glass fiber layer 30, and the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com