Digital flow distribution and speed adjustment type low-speed axial plunger pump

An axial plunger pump and speed regulation technology, applied in the field of hydraulic plunger pump, can solve the problems of continuous and stable adjustment of flow, long service life, heating of friction pair, etc., to extend service life, enhance lubrication and cooling function, improve Adjusting the effect of properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

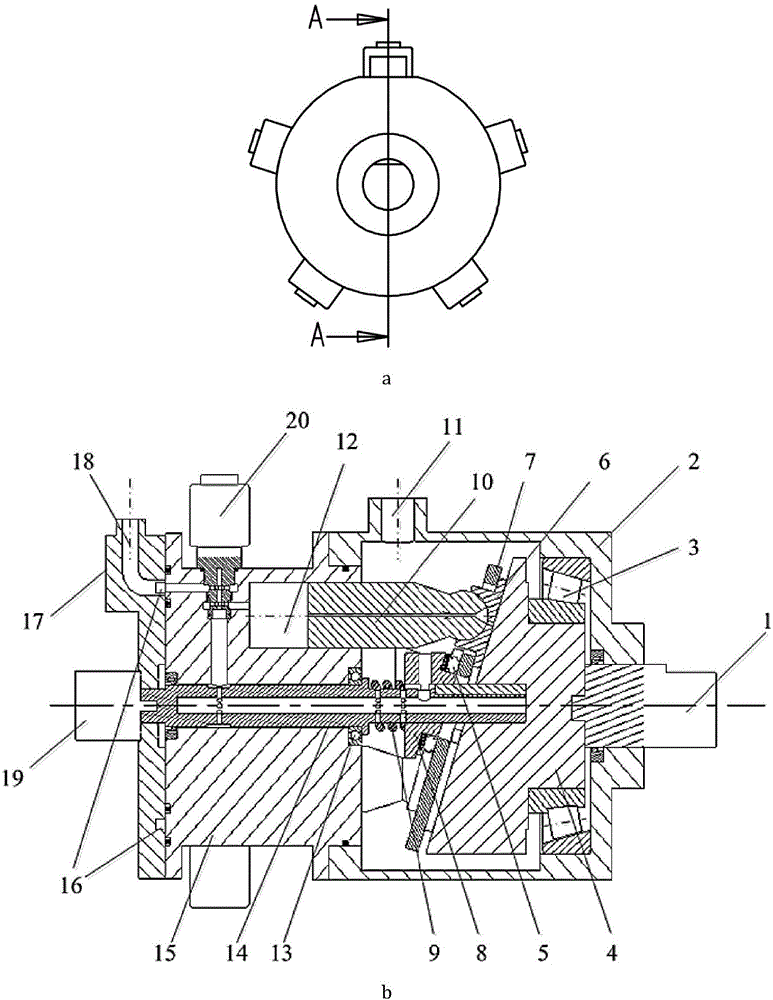

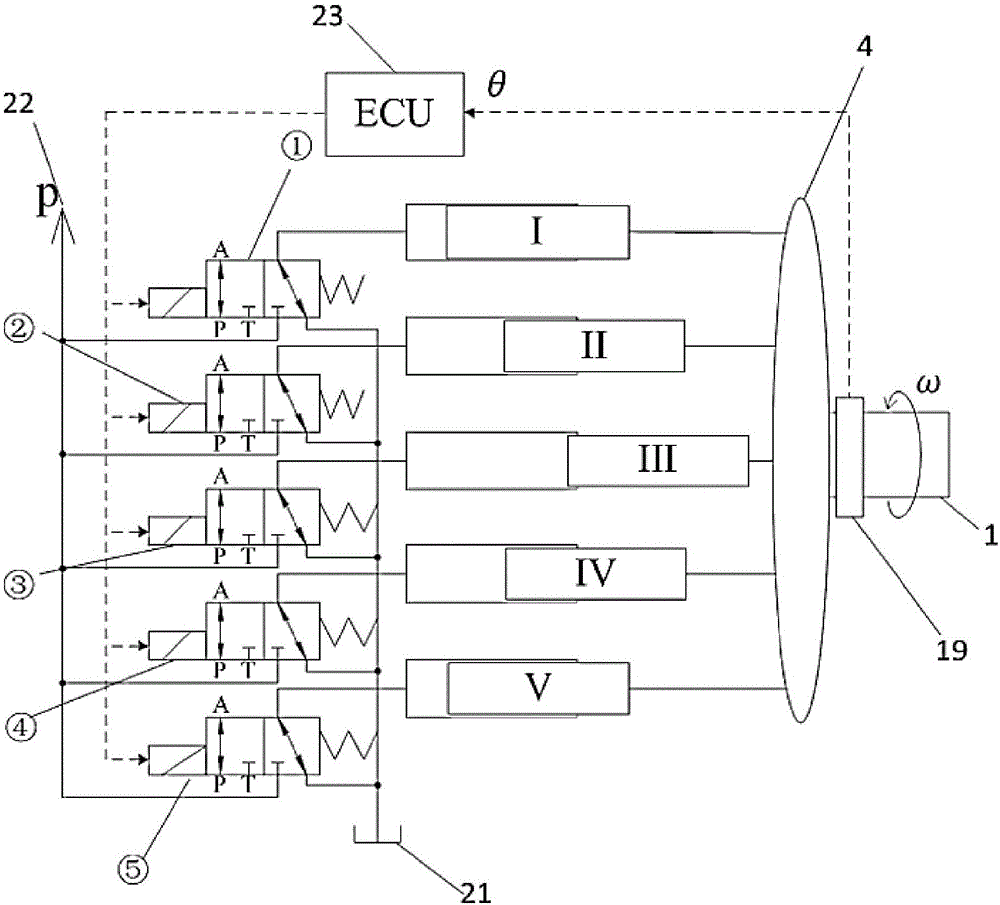

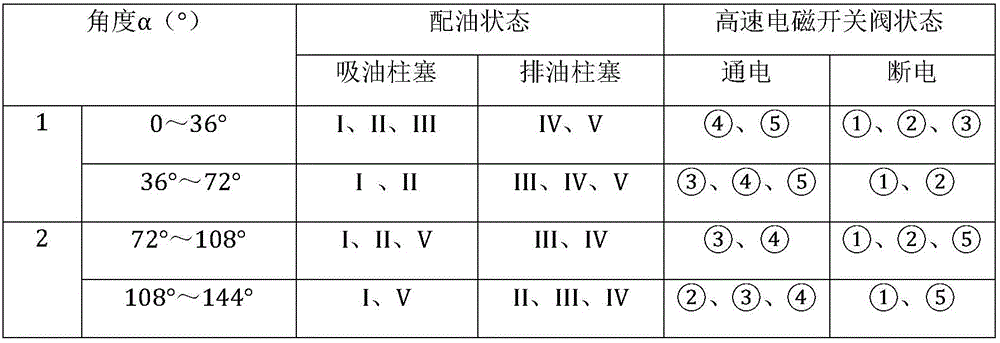

[0019] Such as figure 1 As shown, this embodiment includes: an input shaft mechanism arranged in the low-pressure housing 2, a swash plate 4 connected to the input shaft mechanism, and five sets of plungers 10 with high-speed electromagnetic switching valves 20 in contact with the swash plate 4 And plunger cavity 12 thereof, wherein: the input shaft mechanism is provided with the angle encoder 19 that links to each other with electronic control unit 23, controls five high-speed electromagnetic switch valves 20 respectively by electronic control unit 23; Each high-speed electromagnetic switch valve 20 ( The input ends of I~V) in the figure are connected with the corresponding plunger chambers ①~⑤, the low-pressure port of the output end is connected with the fuel tank 21 through the auxiliary shaft 14, the low-pressure housing 2, and the oil inlet 11, and the high-pressure port is connected with the oil tank 21 through the high-pressure housing 17. The annular groove 16 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com