Skid-mounted lubricating oil circulation device

A technology of circulating device and lubricating oil, applied in transmission parts, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of insufficient lubrication, easy failure of reducer and motor, hidden safety hazards, etc. The effect of automatic monitoring, reducing equipment failure rate and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

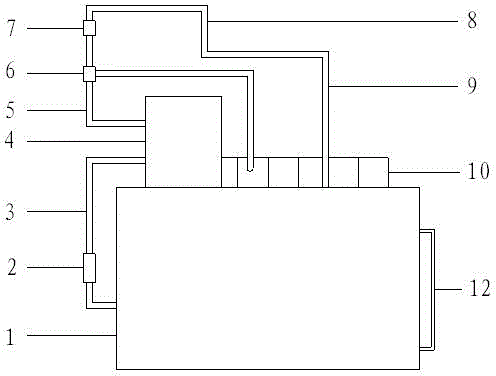

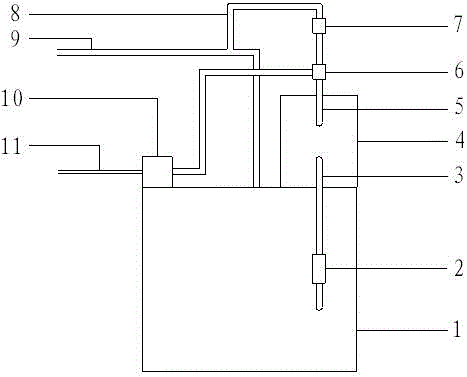

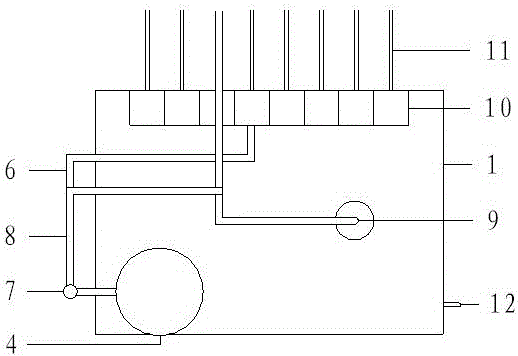

[0019] see figure 1 , figure 2 , image 3 , a skid-mounted lubricating oil circulation device, the oil tank 1 is a skid-mounted structure, as the main support of the device, a circulating oil pump 4 is installed on it, and the circulating oil pump 4 is a diaphragm metering pump suitable for lubricating oil. The circulating oil pump 4 is connected to the oil tank 1 through the circulating oil pump inlet pipeline 3, and the circulating oil pump inlet filter 2 is installed on the circulating oil pump inlet pipeline 3. The outlet pipeline 5 of the circulating oil pump is respectively connected to the main oil supply pipeline 6 and the pressure relief pipeline 8 through a tee. 11 is connected with each agitator reducer oil nozzle that is lubricated. The pressure relief pipeline 8 is connected to the lubricating oil return pipeline 9, so that the lubricating oil discharged from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com