Heater combustion chamber of hypersonic-speed high-enthalpy ground simulation device

A ground simulation, hypersonic technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of narrow working range of head design structure, large parameter change range, flame flameout, etc., and achieve efficient, stable and wide combustion time. The effect of working range and long burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

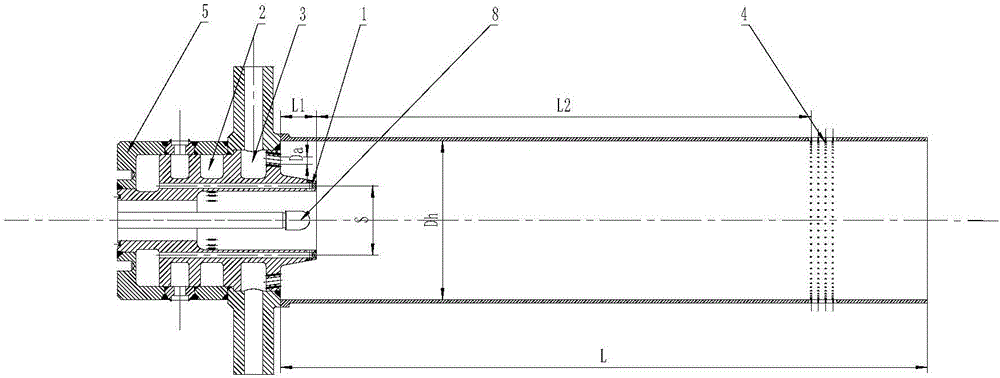

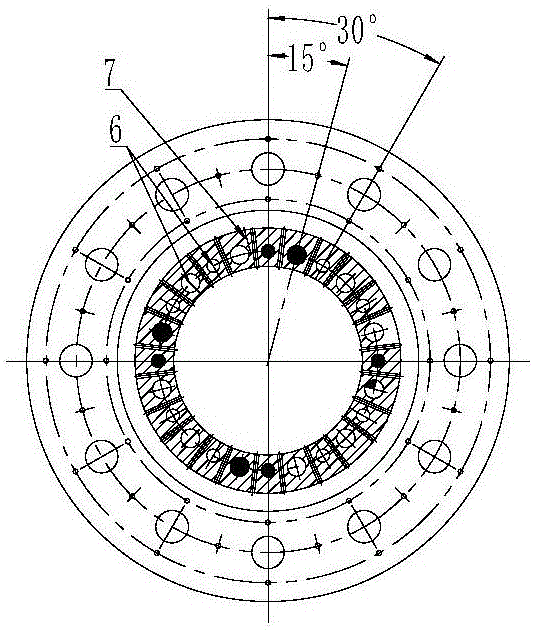

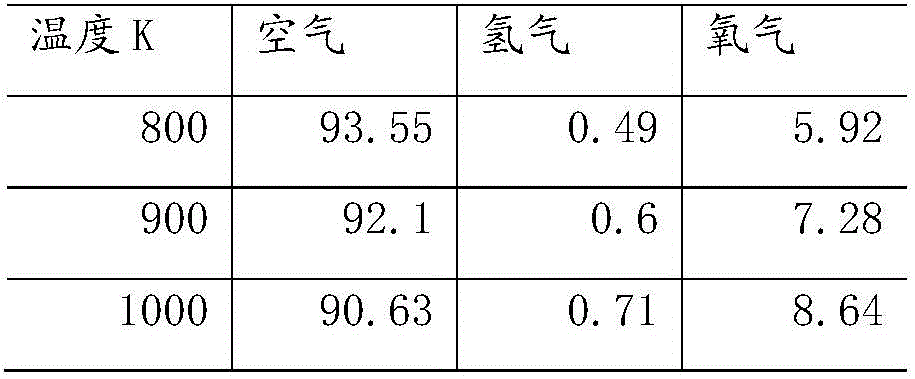

[0010] Such as Figure 1-2 As shown, the heater combustion chamber of this hypersonic high-enthalpy ground simulation equipment, the combustion chamber head is on the left side of the combustion chamber, and the combustion chamber includes a hydrogen-oxygen injection ring injection body 1, an inner ring air injection body 2, The outer ring air injection unit 3, the secondary mixing air injection unit 4; the hydrogen oxygen injection ring injection body, the inner ring air injection body, and the outer ring air injection unit are on the left side of the combustion chamber head 5, The secondary mixed air injection unit is on the right side of the combustion chamber head; the injection body of the hydrogen-oxygen injection ring protrudes from the air flow, and it has hydrogen-oxygen nozzles 6 arranged in a staggered manner, and these hydrogen-oxygen nozzles form the hydrogen-oxygen injection ring 7. Most of the hydrogen-oxygen nozzles are directly injected along the flow directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com