Concave-convex dimpled heat transfer extrusion molding device

A technology for extrusion molding and heat transfer tubes, applied in the direction of forming tools, tubular elements, heat exchange equipment, etc., to achieve the effect of reducing manufacturing production costs, reducing complexity, and better standardizing structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

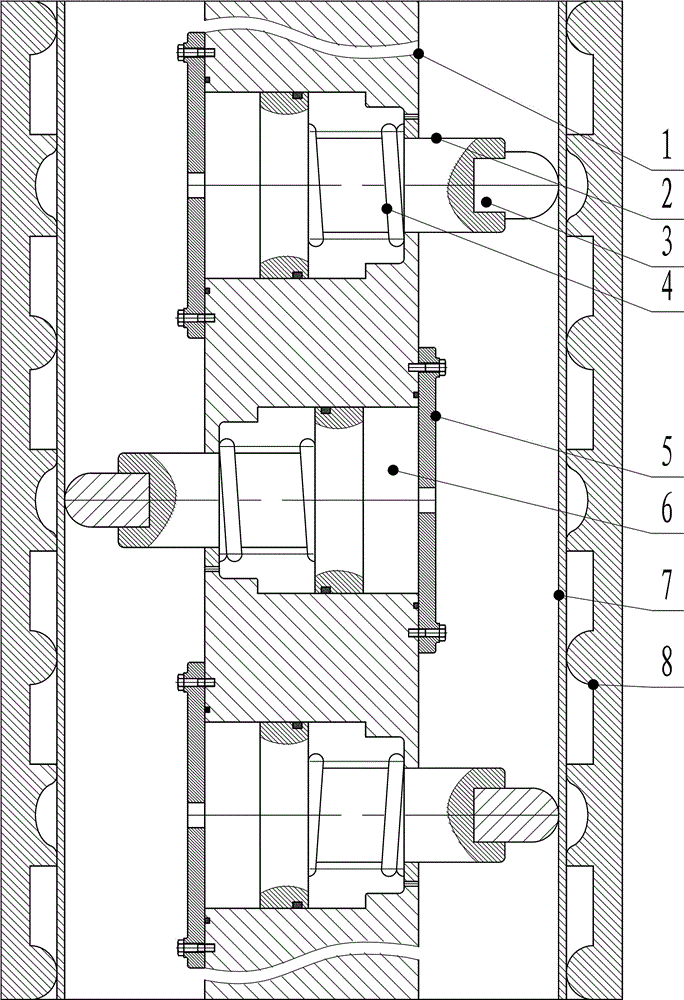

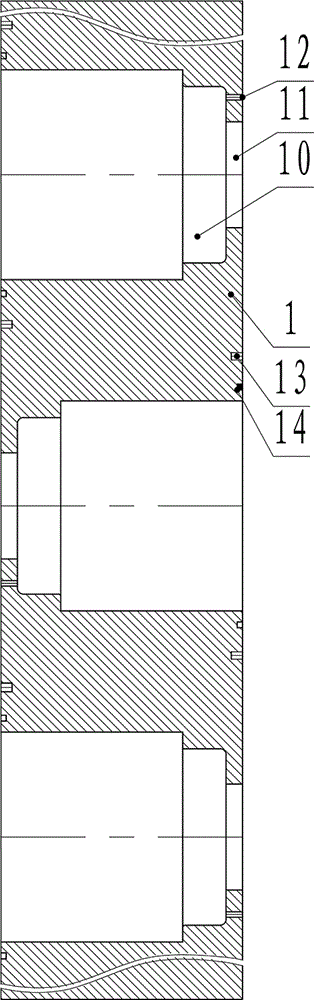

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

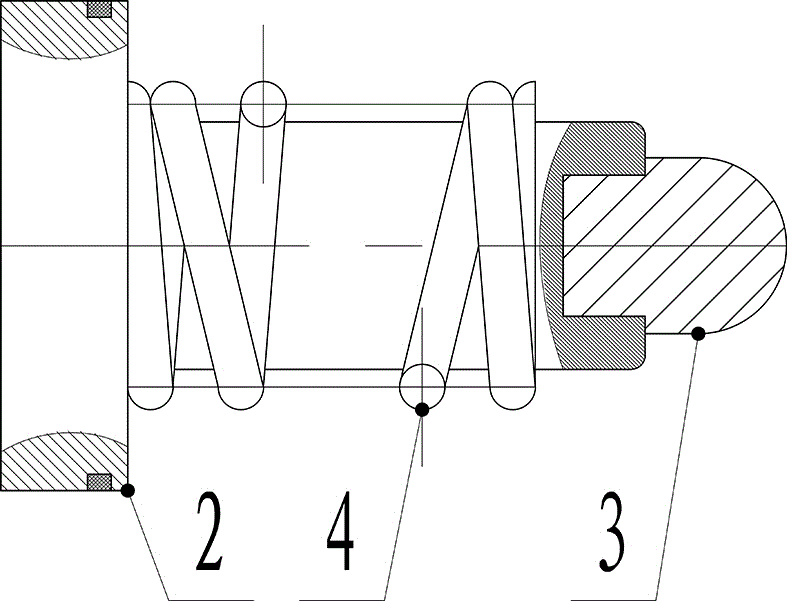

[0018] refer to figure 1 , a concave-convex cell heat transfer tube extrusion molding device, including a cylinder body 1, a piston rod 2, a flange end cover 5, an extrusion head 3, a cylinder barrel 6, a return spring 4, and a concave-convex mold 8, and is characterized in that: There is a circular cavity arranged in a dislocation in the cylinder body 1, and a piston rod 2 is fitted in the circular cavity. The large end of the piston rod 2 is covered with a sealing ring, and the small end of the piston rod 2 is covered with a return spring 4. The small end of the piston rod 2 has an interference An extruding head 3 is cooperatingly installed, and the extruding head 3 is in contact with a light pipe 7, and the light pipe 7 is in contact with a concave-convex mold 8.

[0019] The working principle of the device is: hydraulic oil flows into the cylinder barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com