Nuclear power plant steam generator water chamber partition weld seam penetration testing equipment

A steam generator, penetration testing technology, which can solve the problems of poor penetration visualization, complex structure and high manufacturing cost by detecting the appearance of fluid at the leak point, chemical instruments and methods, optical testing flaws/defects, etc. , to achieve the effect of overcoming the blind spot of penetration inspection, reducing the collective dose, and reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

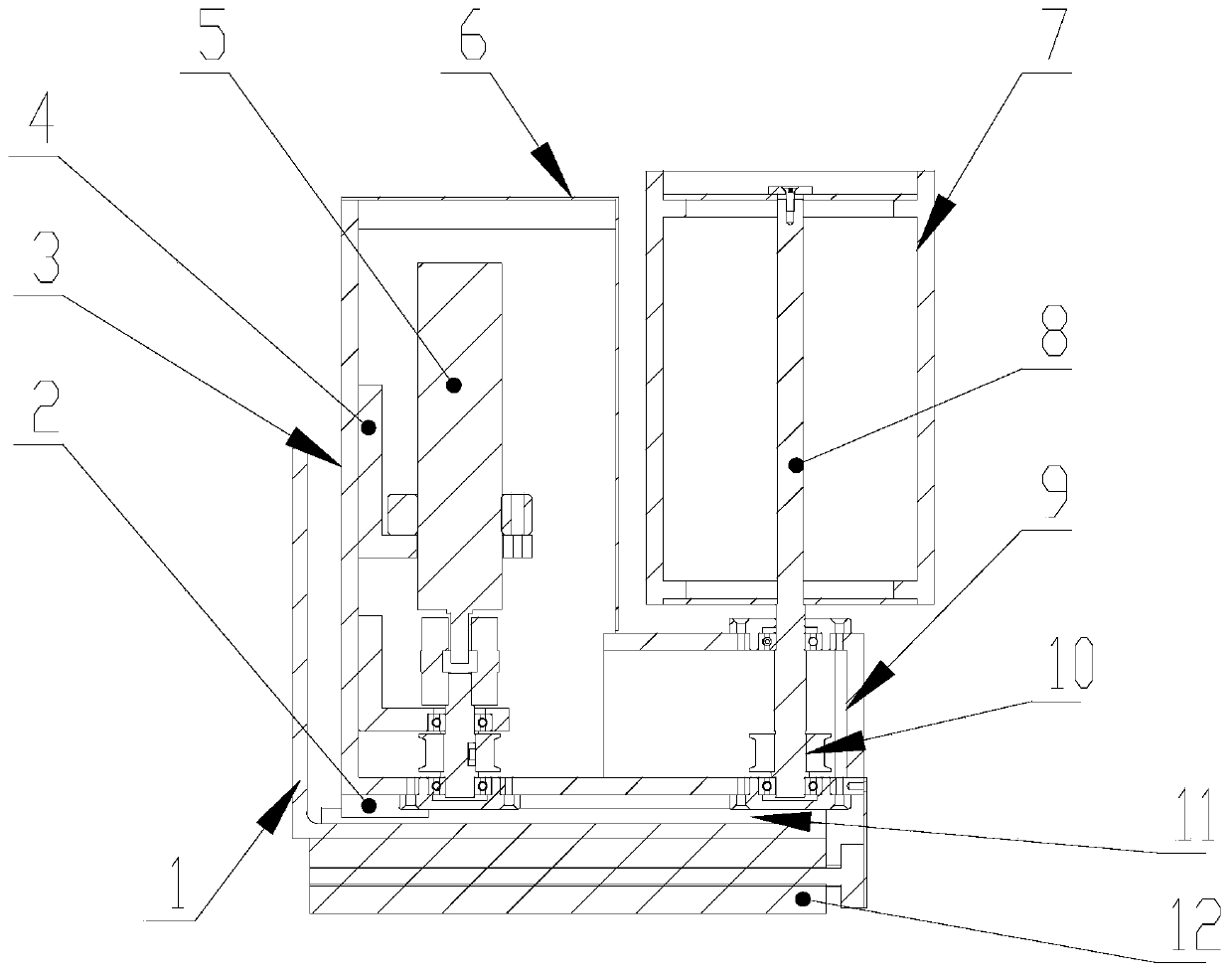

[0022] Such as figure 1 , 2 As shown, the welding seam inspection equipment for the water chamber partition plate of the nuclear power plant steam generator includes a cleaning tool for cleaning the weld seam, a penetration tool for spraying various reagents on the weld seam, and sending the cleaning tool and penetration tool to the weld seam And a conveying mechanism that moves along the weld seam (the conveying mechanism can be a manipulator or a conveying track, which is not the focus of the present invention, and will not be described in detail here).

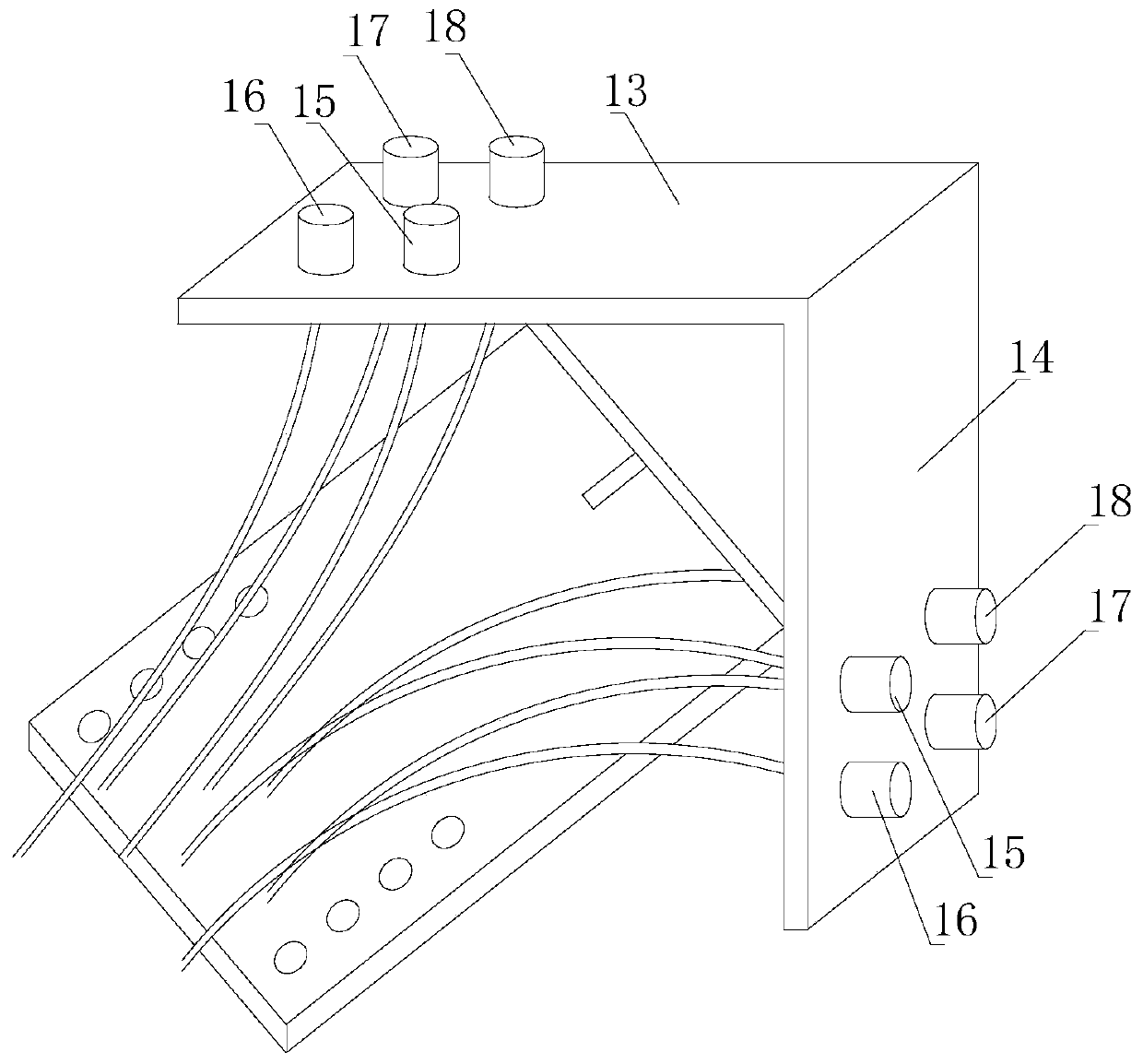

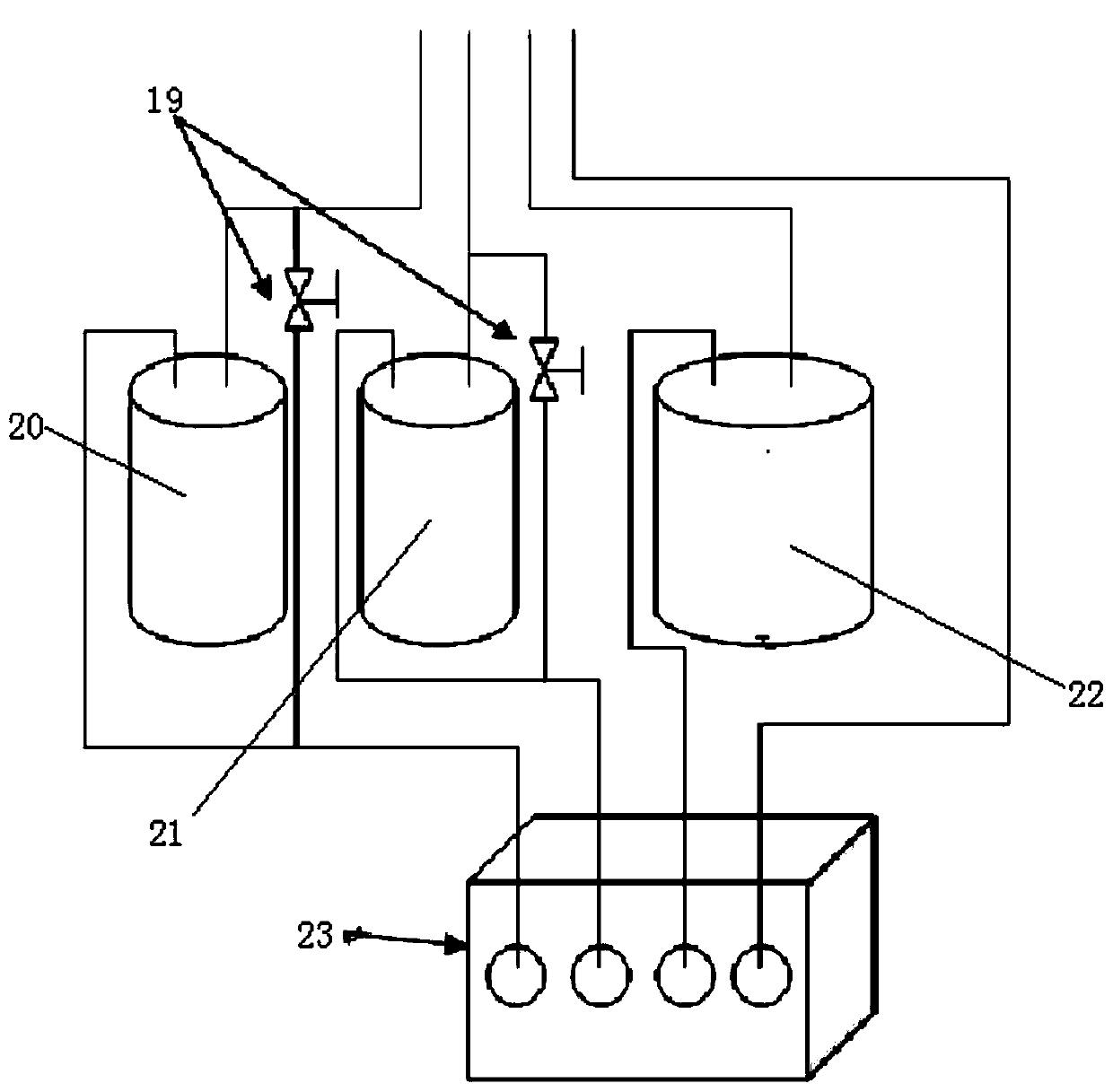

[0023] Such as figure 1 , 3 As shown, the infiltration tool includes a mounting frame, at least one spray head assembly connected to the mounting frame, a pressure tank for respectively providing spray for the spray head assembly, and a connection between the spray head assembly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com