Pulping machine shell machining method and pulping machine shell locating fixture

A technology for positioning fixtures and refiners, which is applied in the field of papermaking equipment, can solve the problems of affecting the processing accuracy, product processing quality, high labor intensity, and equipment utilization rate reduction, so as to shorten processing time, improve processing quality, and equipment utilization rate. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

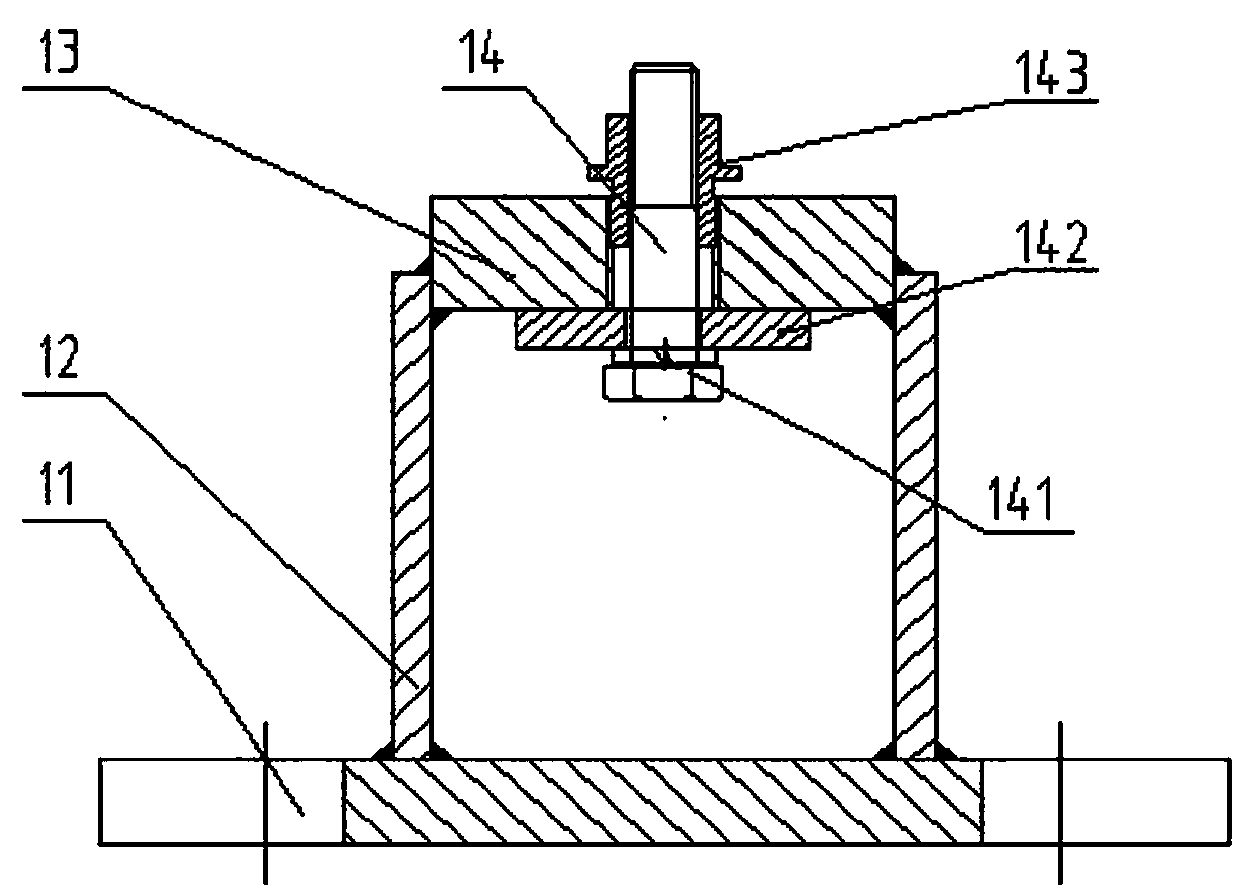

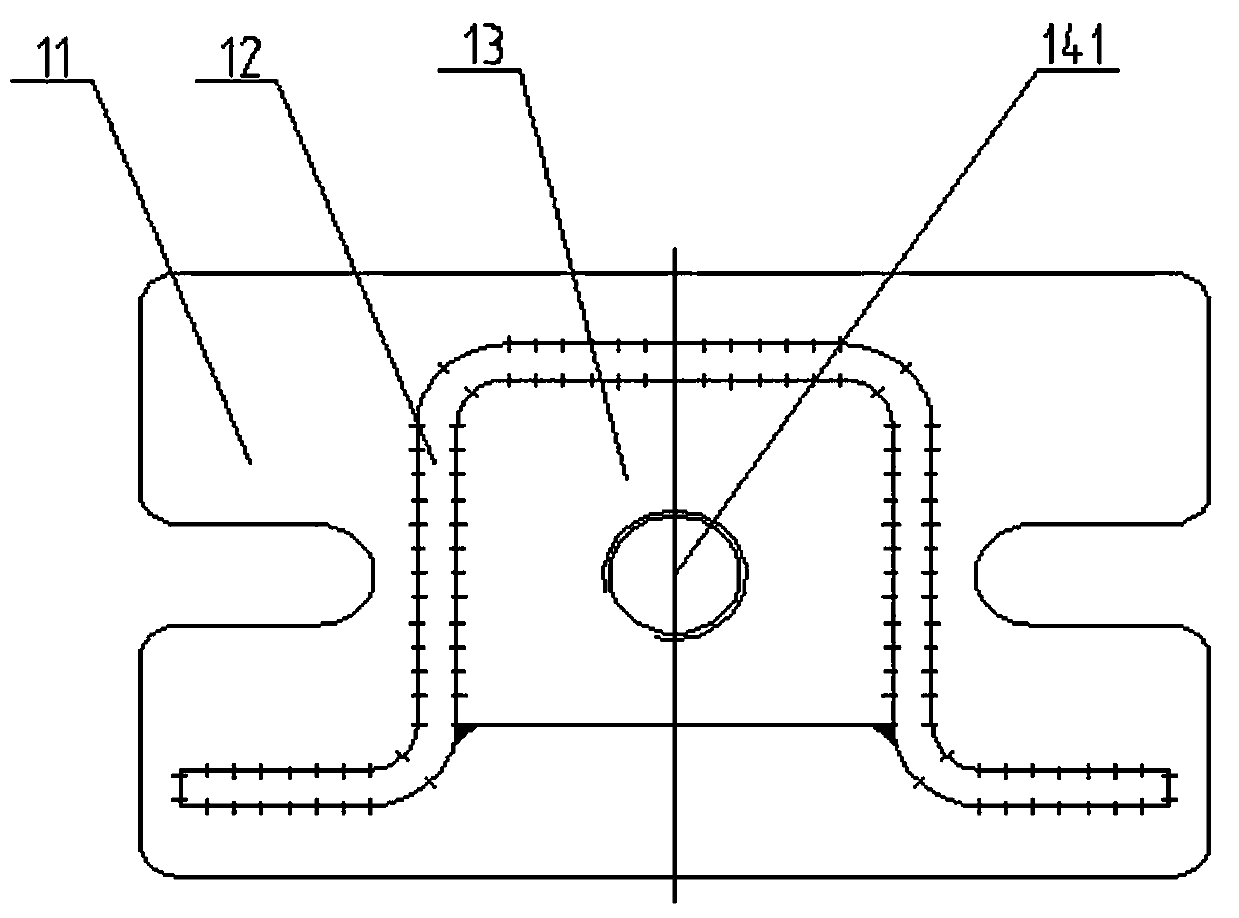

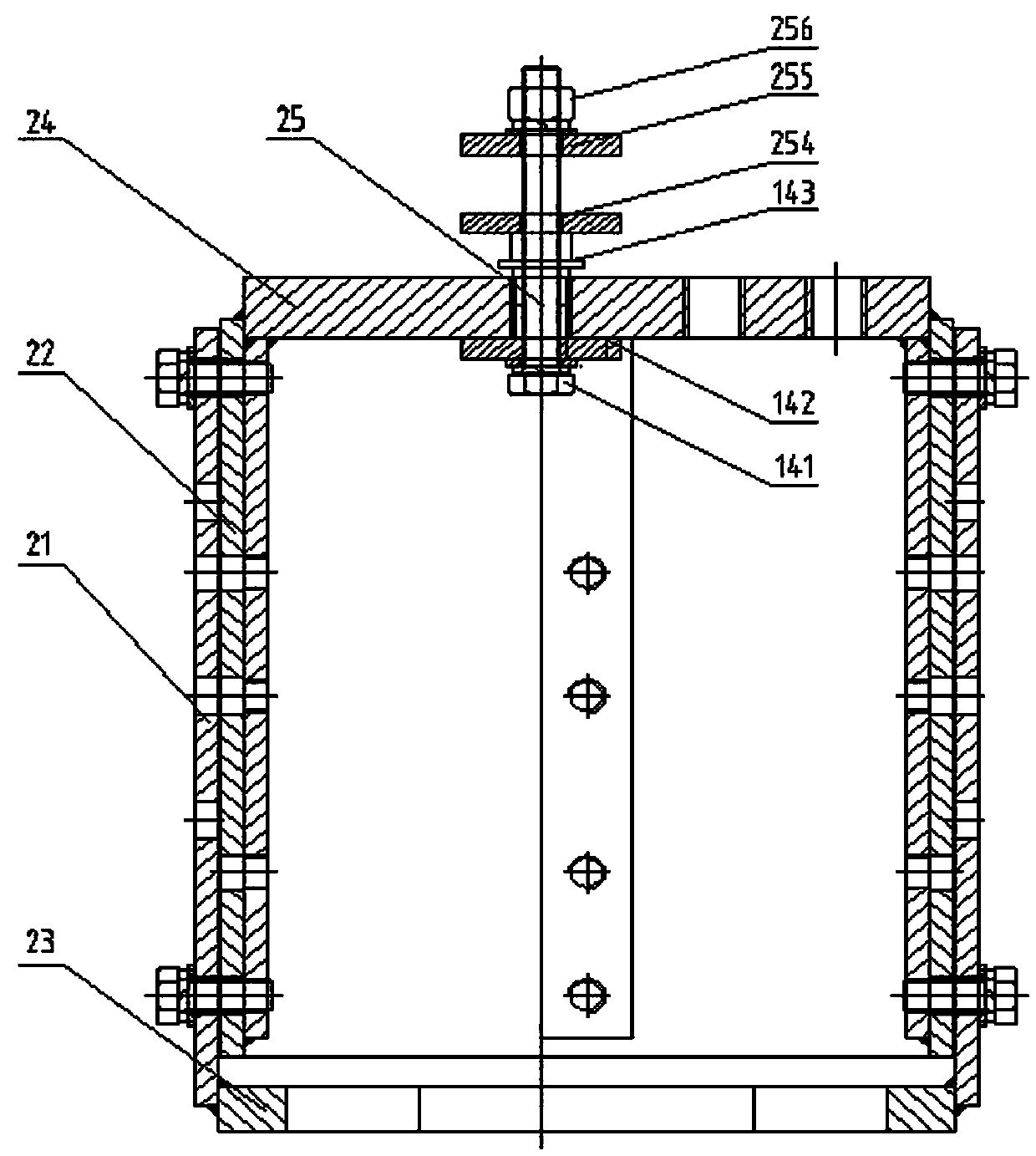

[0038] Such as Figure 1-7 As shown, in order to realize the positioning and clamping of the refiner shell, one clamping can realize the machining of multiple end surface structures, the present invention designs a positioning fixture for the refiner shell, including bottom tooling 1 and side tooling 2 , bottom tooling 1 is used for positioning the bottom surface of the refiner shell, side tooling 2 is used for positioning the side of the refiner shell, bottom tooling 1 and side tooling 2 cooperate to complete the positioning and clamping of the refiner shell .

[0039] For convenience of description, such as Figure 5-9 As shown, the end faces of the refiner shell of the workpiece to be processed are respectively set as A1 end face 41, A2 end face 42, A3 end face 43, A4 end face 44; B direction B5 end face 5; E direction E6 end face 6 , During the use of the refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com