Optical system distortion measuring method based on Shack-Hartmann wave-front sensor

An optical system and measurement method technology, applied in the direction of geometric characteristics/aberration measurement, testing optical performance, etc., can solve problems such as the inability to meet the application problems of large-diameter and large-field telescopes, and achieve enhanced versatility and scalability. Measurement cost and effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

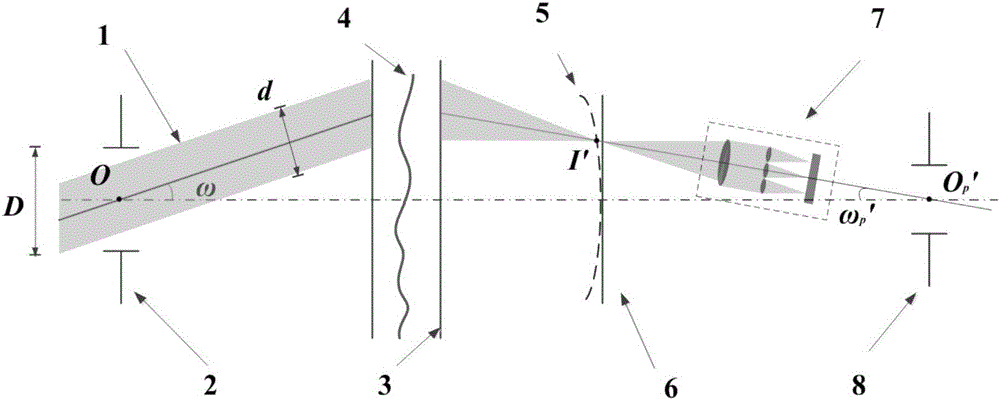

[0026] The principle of optical system distortion measurement involved in the present invention is shown in figure 1 , mainly including the parallel light source 1, the entrance pupil 2 of the optical system under test 3, the optical system under test 3 and its wave aberration 4, the actual image plane 5, the Gaussian image plane 6, the Shaker-Hartmann wavefront sensor 7 and Exit pupil 8.

[0027] In the measurement method of the present invention, a small-caliber parallel light source 1 is used for measurement, and the diameter is smaller than that of the measured optical system 3, which can be selected according to the size of the wave aberration 4 of the measured optical system 3 and the requirements for distortion measurement accuracy. The parallel light source 1 needs to rotate around the center of the entrance pupil 2 of the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com