Monitoring device and monitoring method for water content of coal powder and coal type on basis of multiple sensors

A multi-sensor and monitoring device technology, applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problem of inability to guide power plants, real-time adjustment of pulverizing systems and boiler combustion parameters, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

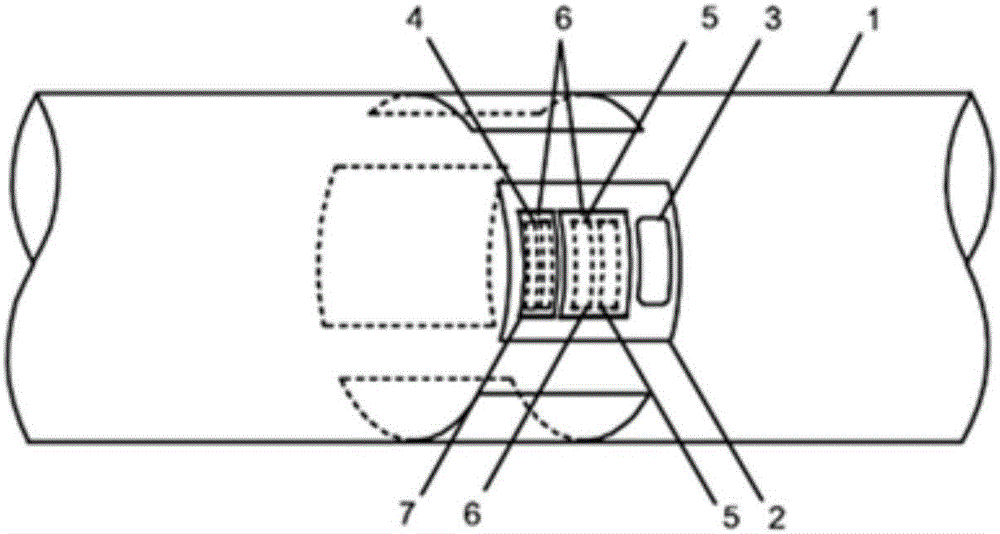

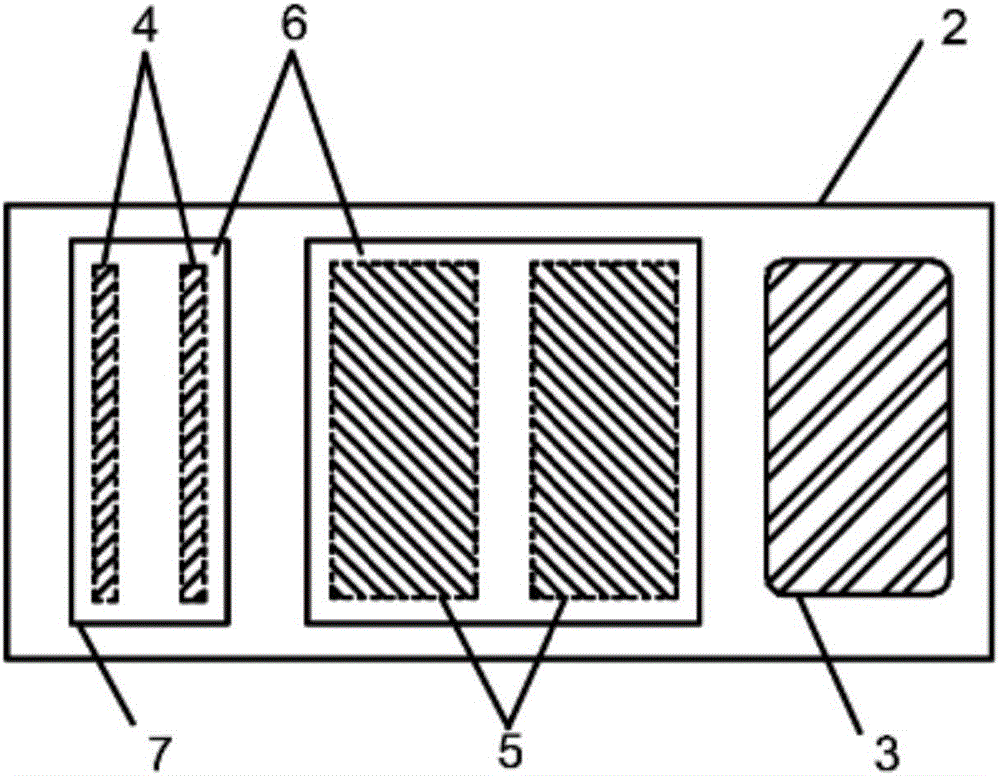

[0033] The invention provides a method and device for monitoring the moisture content of pulverized coal and coal type based on multi-sensors, which can realize the real-time detection of the moisture content of pulverized coal and coal type in a circular pipeline, and the strip electrode is not affected by the shape of the pipeline and is easy to install .

[0034] Below in conjunction with accompanying drawing and implementation example the present invention will be further described:

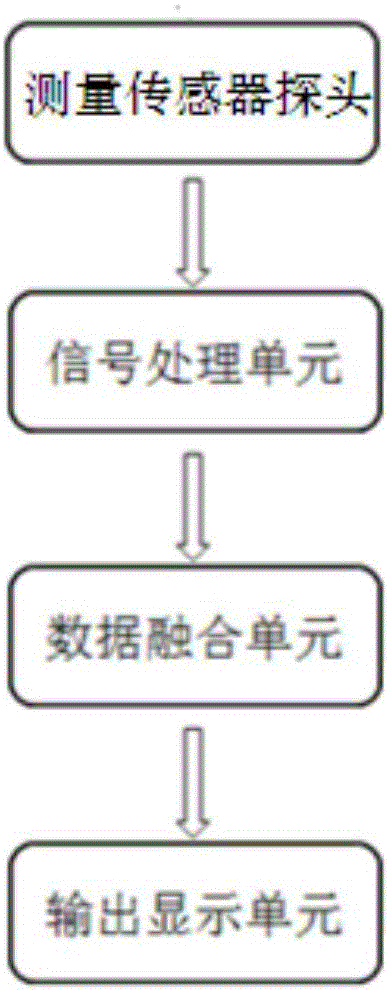

[0035] The composition block diagram of a multi-sensor based monitoring device for coal moisture content and coal type is as follows: figure 1 As shown, it is composed of a measurement sensor probe 2, a signal processing unit, a data fusion unit and an output display unit connected in sequence; the measurement sensor probe 2 is composed of a temperature sensor 3, a speed measurement electrode 4 and an electrostatic signal measurement electrode 5, and is made of an insulating material 6 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc length | aaaaa | aaaaa |

| Axial width | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com