Rough set and ANFIS (adaptive neuro-fuzzy inference system) based quantitative analysis method for relation between glass batch and quality

A glass batch material, quantitative analysis technology, applied in the direction of analyzing materials, measuring devices, material inspection products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

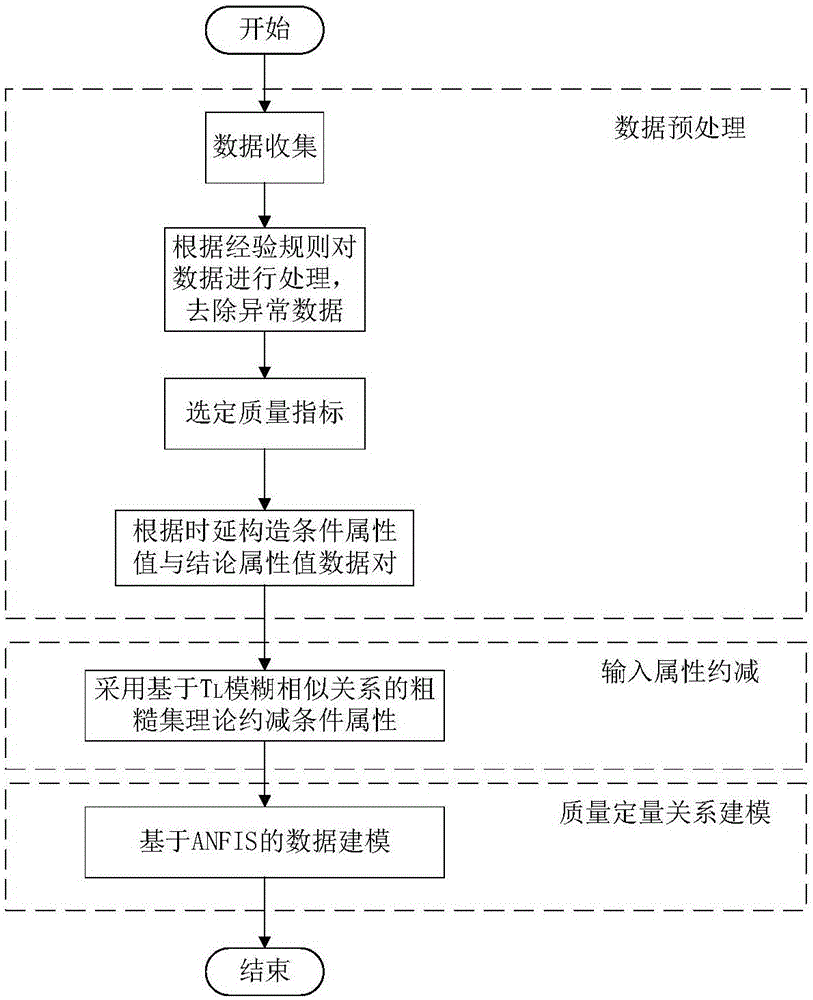

[0084] In order to better understand the technical scheme of the present invention, figure 1 A flow chart of the method of the present invention is given. The method includes:

[0085] Step (1): Data collection and preprocessing

[0086] The present invention collects the weight and proportion data of ingredients, moisture and alkali content from the DCS control system of the glass melting furnace every 4 hours; collects the grade data of the finished glass product every hour; collects the defect data of the finished glass every 8 hours; According to the law that the glass production process takes about 2.5 hours from the feeding of glass batch materials to the output of finished products, the batch composition data and the quality data of glass products after 2.5 hours are composed of data pairs for data modeling.

[0087] Step (2): Reduction of influencing factors based on fuzzy rough set theory

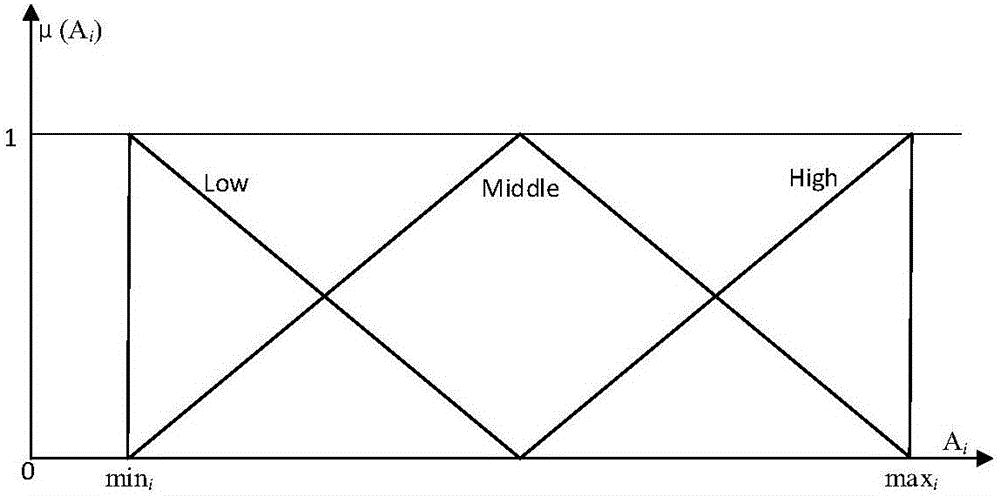

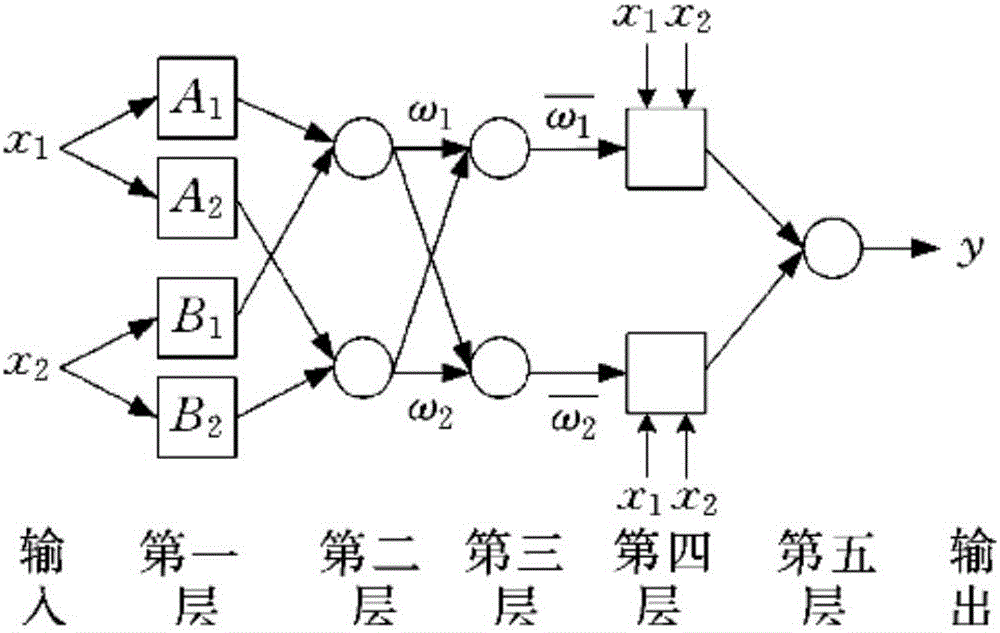

[0088] Step (2.1): Let R be the reduced attribute set of the conditional a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com