Single-polarization fiber polarizer structure with light-absorption coating layer

A single-polarization optical fiber and polarizer technology, which is applied in the coupling of optical waveguides, instruments, optics, etc., can solve the problems of unsatisfactory use requirements, high brittleness of D-type optical fibers, complicated manufacturing process, etc., and is suitable for mass engineering The effect of production and use, low cost and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

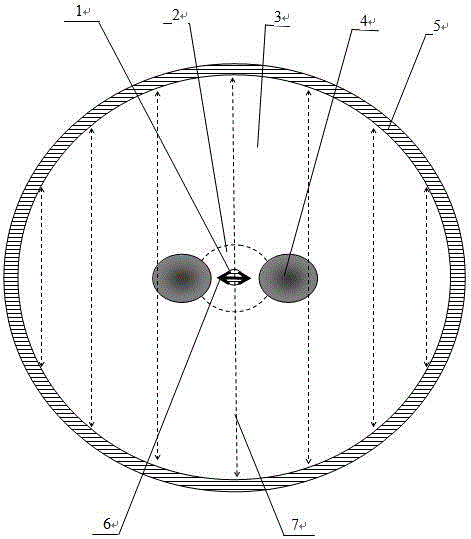

[0014] refer to figure 1 , a single-polarization fiber polarizer structure with a light-absorbing coating layer includes a single-polarization fiber core 1, a single-polarization fiber inner cladding 2, a single-polarization fiber outer cladding 3, a single-polarization fiber stress applying unit 4, and a single-polarization fiber HE transmitted by fiber core 1 11x Guided mode 6 and HE propagating in the outer cladding 3 of single-polarized fiber 11y Cut-off mode 7, this single polarization fiber polarizer structure has a layer of light-absorbing coating 5 on the surface of the single polarization fiber outer cladding 3.

[0015] The single-polarization fiber polarizer structure is not limited to the outer diameter of the single-polarization fiber, which can be various diameters such as Ф125 μm, Ф80 μm, Ф45 μm, etc.; its shape is not limited, and can be cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com