Mems vibrating mirror for suppressing laser speckle and manufacturing method thereof

A laser speckle and laser technology, applied in the direction of mirrors, optics, optical components, etc., can solve the problems of light energy loss, high cost, poor process controllability, etc., to reduce the loss of light energy, reduce the loss of light energy, The effect of enhancing the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

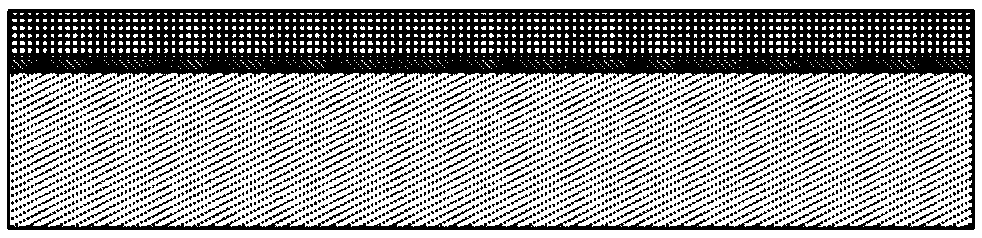

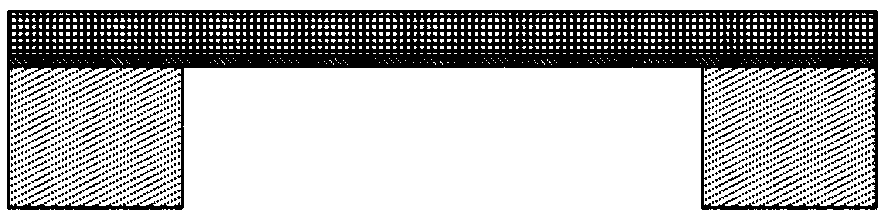

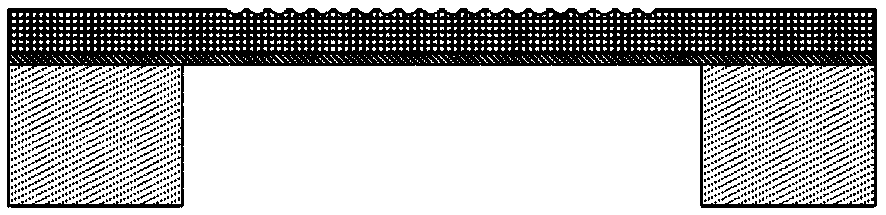

Method used

Image

Examples

Embodiment Construction

[0033] See Picture 9 As shown, the working schematic diagram of the MEMS galvanometer of the present invention in the laser display system. The schematic diagram includes a laser source 1, a MEMS galvanometer, a short focal length optical plano-convex lens 2, a homogenizing tube 4, a laser display chip 5, and a display screen 6. The MEMS galvanometer is located on the exit light path of the laser source 1, passing through the MEMS galvanometer Phase interference and specular reflection convert the highly coherent incident light from the laser source 1 into outgoing light with an uneven phase difference. The outgoing light with a certain scattering cone angle passes through the convergence, homogenization and focusing of the front short focal length plano-convex lens, the homogenizing tube 4 and the rear short focal length plano-convex lens, and then enters the laser display chip 5 and is finally projected onto the display screen 6.

[0034] See Figure 7 As shown, the MEMS galv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com