Locomotive traction calculation model calibration method based on actual operation data

A traction calculation and actual operation technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve problems such as inaccuracy, inaccuracy, and lack of data, to ensure adaptability and accuracy, and reduce statistical errors. , good adaptability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

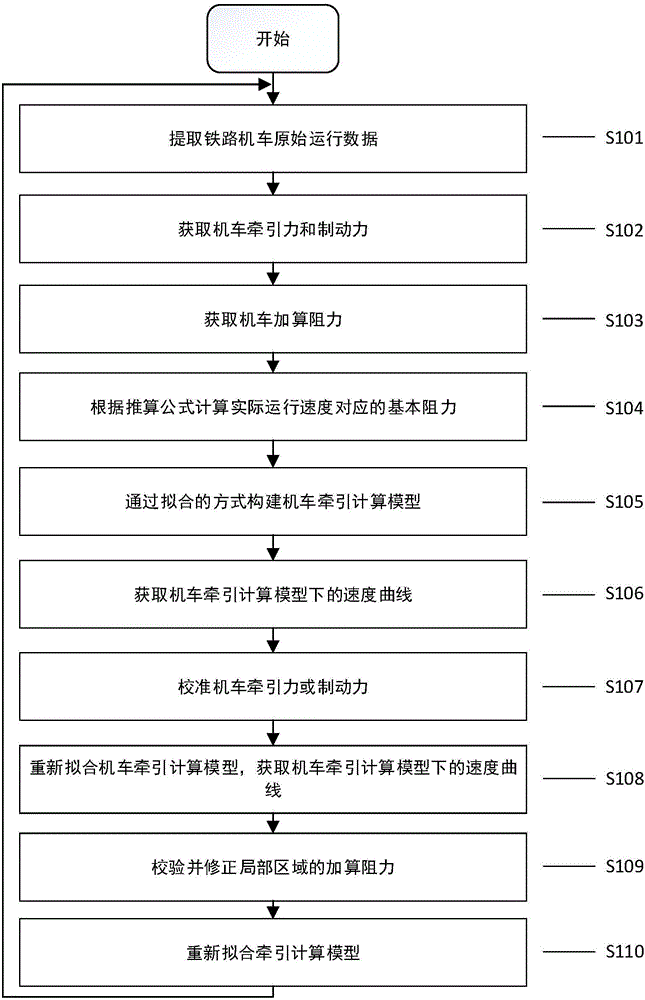

[0038] In order to make the present invention clearer, the present invention is described in detail below in conjunction with accompanying drawing: as figure 1 Shown is a schematic flow chart of a locomotive traction calculation model calibration method based on actual operating data provided by the present invention.

[0039] In general, the model calibration process of the present invention includes two parts: reverse fitting and forward verification:

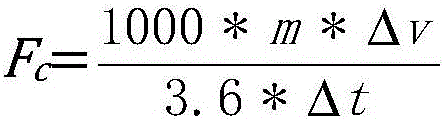

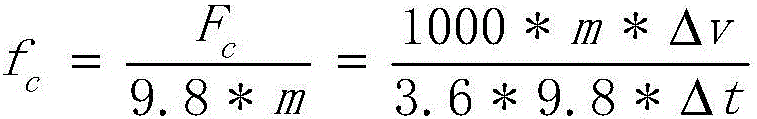

[0040] The reverse fitting part includes collecting the original running data of the locomotive, obtaining the traction force and braking force of the locomotive according to the original running data of the locomotive, and further obtaining the added resistance of the locomotive, and then obtaining the speed curve of the driver operating the locomotive by analyzing the running data of the locomotive, and calculating the corresponding The basic resistance under the speed and gear, and finally the corresponding locomotive tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com