Method of recognizing circular defects based on weld X-ray digital images

A defect recognition and digital image technology, applied in image enhancement, image analysis, image data processing, etc., can solve the problems of low recognition rate of circular defects, difficult programming, complex mathematical and physical models, etc., to improve detection speed and accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The circular defect recognition method based on the weld X-ray digital image of the present invention is suitable for the circular defect detection of the weld.

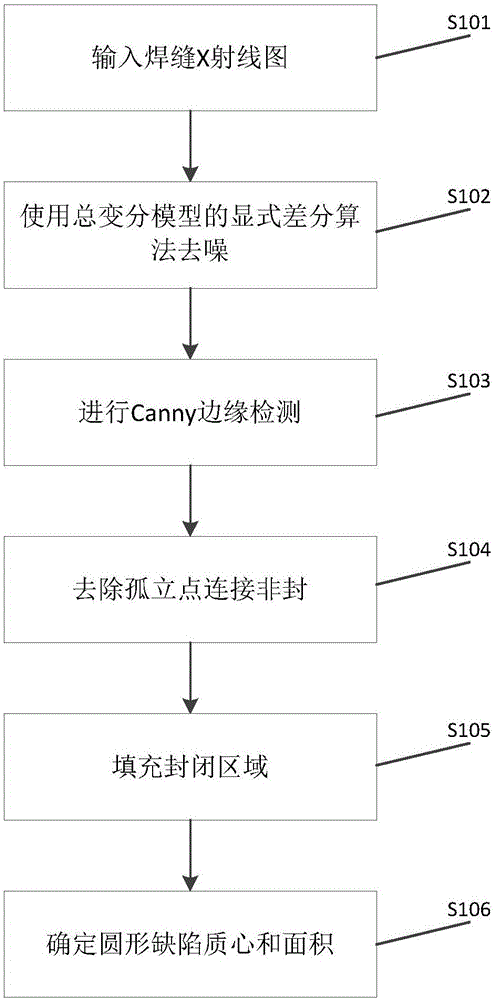

[0024] figure 1 Shown is a flowchart according to an embodiment of the invention. Including steps S101-S106, which are specifically as follows:

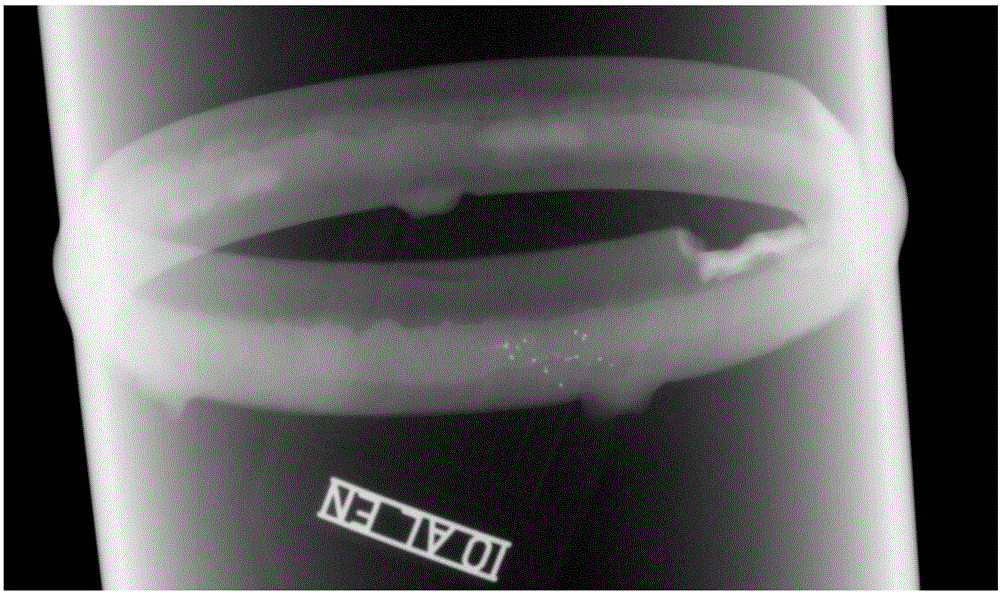

[0025] S101, placing the weld to be inspected under the X-ray non-destructive detector, acquiring the X-ray image of the weld through X-ray imaging, and collecting the X-ray image of the weld with a circular defect;

[0026] S102, performing denoising processing on the X-ray image of the weld;

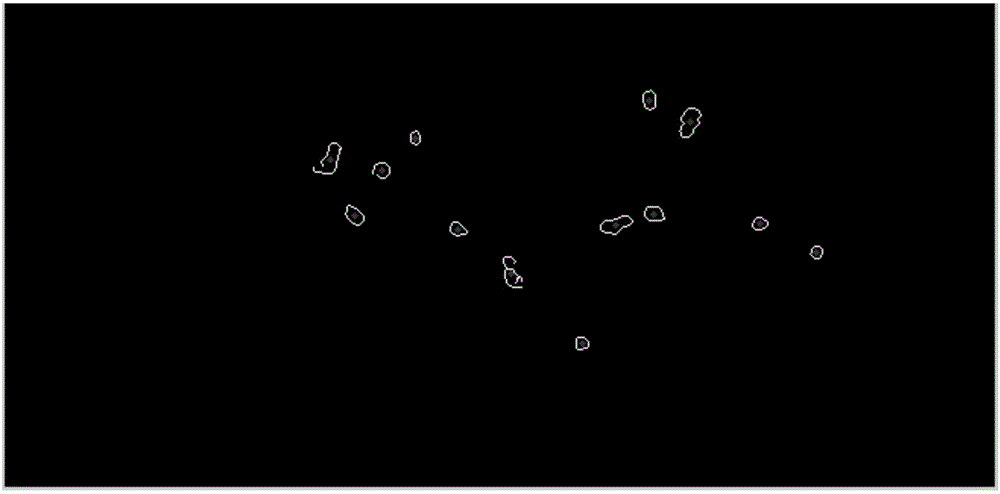

[0027] S103, initially determining the edge of the circular defect through the Canny edge detection operator;

[0028] S104, use morphological openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com