Frameless film photovoltaic cell pack

A thin-film photovoltaic cell, photovoltaic cell technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of different widths of butyl rubber, affect the appearance, cannot be made very wide, etc., achieve color controllable, extended use life, and the effect of preventing electric leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

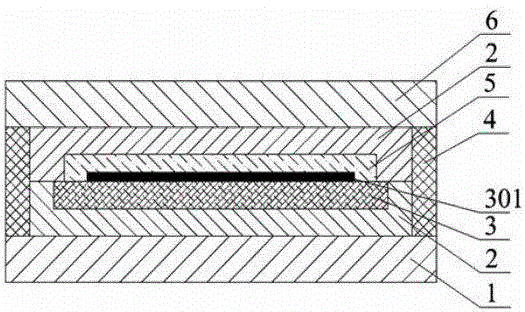

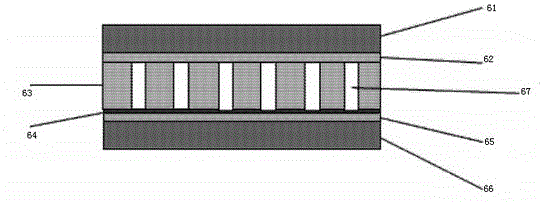

[0016] The present invention will be further described below in conjunction with accompanying drawing and embodiment: Figure 1-2 As shown, a frameless thin-film photovoltaic cell module is mainly composed of front glass 1, adhesive film 2, photovoltaic cell core plate 3, film layer 301, butyl glue 4, insulating paint film 5 and back plate 6, wherein the front plate Glass 1 is ultra-clear tempered glass. The adhesive film 2 is PVB or EVA, and the photovoltaic cell core board 3 is an amorphous silicon thin-film solar cell with glass or polymer material as the substrate. The insulating paint film 5 is a modified silicone resin, which has insulation and aging resistance, good surface toughness and high adhesion by adding ultrafine silicon dioxide particles.

[0017] Remove the film layer 301 on the edge of the photovoltaic cell core board 3, weld the electrode lead-out strips on the positive and negative electrodes of the photovoltaic cell core board, and coat the insulating pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com