Improved LED (light-emitting diode) bracket production process

A technology of LED bracket and production process, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult operation and low precision of the production process, and achieve the effects of reducing defective rate, high precision and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

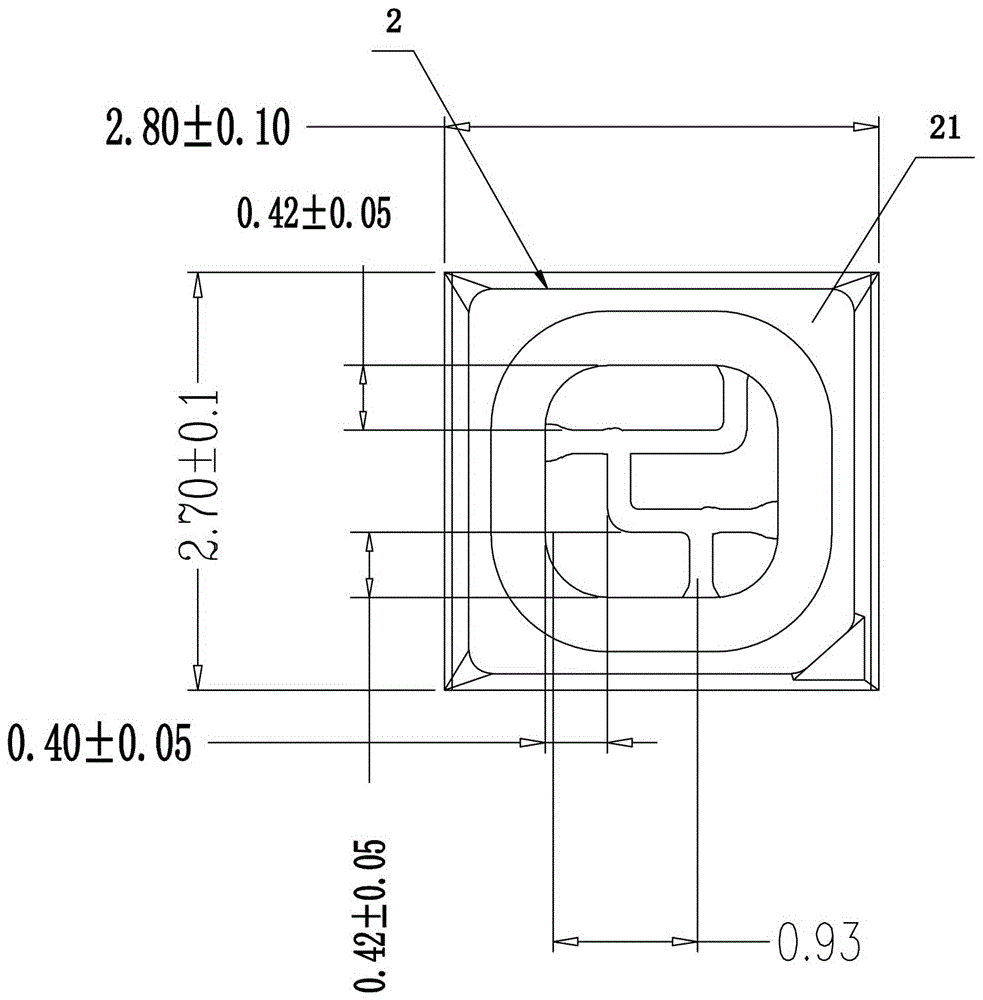

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

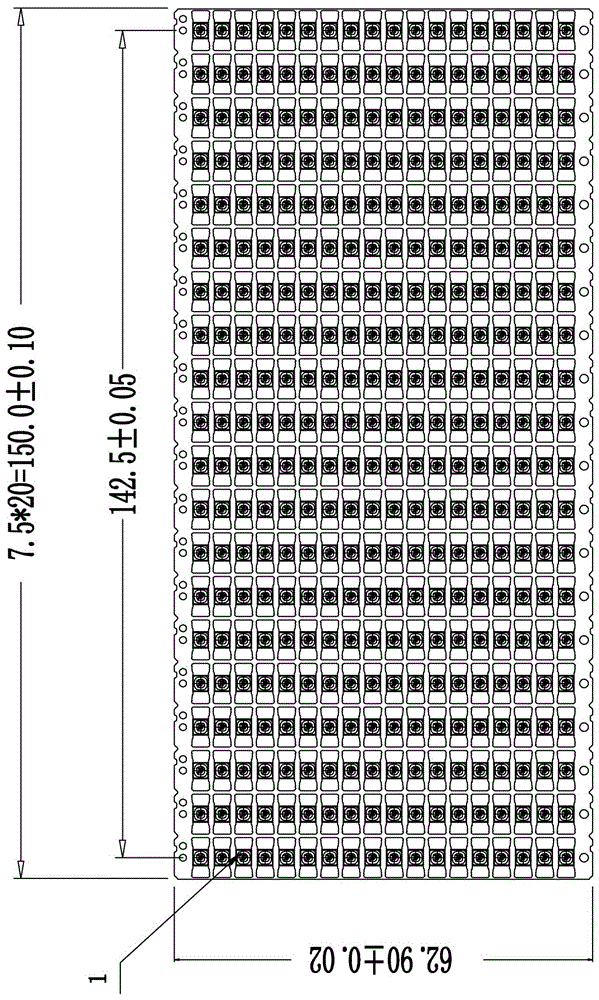

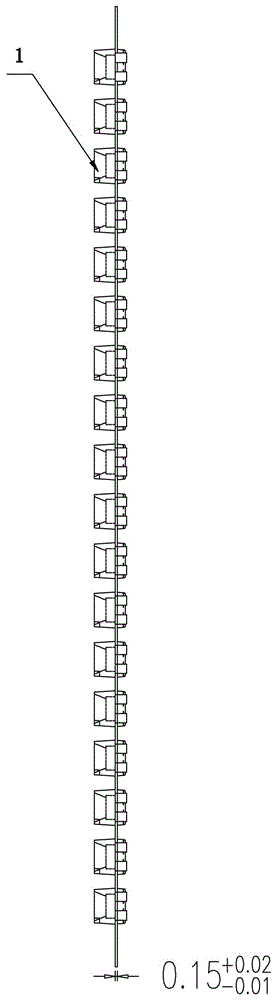

[0026] refer to figure 1 , figure 2 , image 3 and Figure 4 . An improved LED bracket production process, comprising the following steps:

[0027] step one

[0028] Put the plastic inside the 3D printer. The plastic can be EMC.

[0029] EMC-Epoxy Molding Compound is epoxy resin molding compound and epoxy molding compound. It is made of epoxy resin as matrix resin, high-performance phenolic resin as curing agent, silicon micropowder as filler, and various additives. Formed powder molding compound.

[0030] step two

[0031] Input the required model drawings of the LED bracket 1 into the computer, and then control the 3D printer through the computer to print the LED bracket 1 into shape.

[0032] step three

[0033] A layer of copper is electroplated on the outer layer of the printed LED bracket.

[0034] step four

[0035] A nickel layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com