Polyethylene microporous membrane and preparation method of polyethylene microporous membrane

A microporous diaphragm, polyethylene technology, applied in the direction of separators/films/diaphragms/spacers, electrical components, circuits, etc. Stability and safety, improved thickness uniformity, improved poor ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a preparation method of a polyethylene microporous diaphragm, comprising the following steps:

[0023] A) mixing ultra-high molecular weight polyethylene with white oil to obtain oil flakes through melt extrusion and casting;

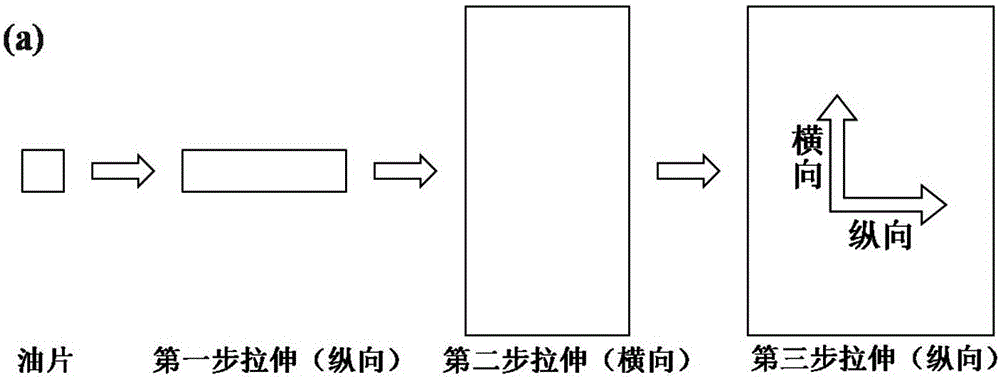

[0024] B) Stretching the oil sheet in the first step in the direction of casting, stretching in the second step perpendicular to the direction of casting, and stretching in the third step in accordance with the direction of casting to obtain a film;

[0025] The stretching strain of the first step is 1-4, the stretching strain of the second step is 5-7, and the stretching strain of the third step is 1-4;

[0026] The stretching temperatures of the first step stretching, the second step stretching and the third step stretching are independently 95-105°C, and the first step stretching, the second step stretching and the third step stretching The stretching speed is independently 1-3mm / s.

[0027] see figure 1 , figure 1 T...

Embodiment 1

[0043] Put ultra-high molecular weight polyethylene and white oil into the mixing container at a ratio of 2:8, stir well and use for melt extrusion. The molecular weight of ultra-high molecular weight polyethylene is 340,000 g / mol. After the mixture of polyethylene and white oil is extruded by a twin-screw extruder, an oil sheet is formed on a casting roll. During casting, the roll temperature was set at 60° C., and the thickness of the obtained oil sheet was 0.9 mm.

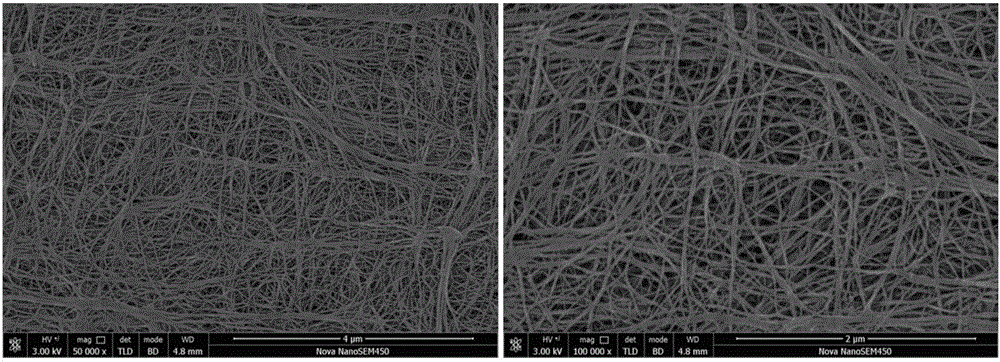

[0044] Two-way three-step stretching is carried out on the oil sheet by using a film bidirectional stretching device. The stretching temperature was 100° C., and the stretching speed was 3 mm / s. The first step of the three-step stretching process is stretching along the longitudinal direction to a strain of 4, the second step is stretching along the transverse direction to a strain of 7, and the third step is stretching along the longitudinal direction to a strain of 1. The parameters of the three-step stretch...

Embodiment 2

[0052] Add ultra-high molecular weight polyethylene and white oil into the mixing container at a ratio of 5:5, stir well and use for melt extrusion. The molecular weight of ultra-high molecular weight polyethylene is 470,000 g / mol. After the mixture of polyethylene and white oil is extruded by a twin-screw extruder, an oil sheet is formed on a casting roll. During casting, the roll temperature was set at 30° C., and the thickness of the obtained oil sheet was 1.5 mm.

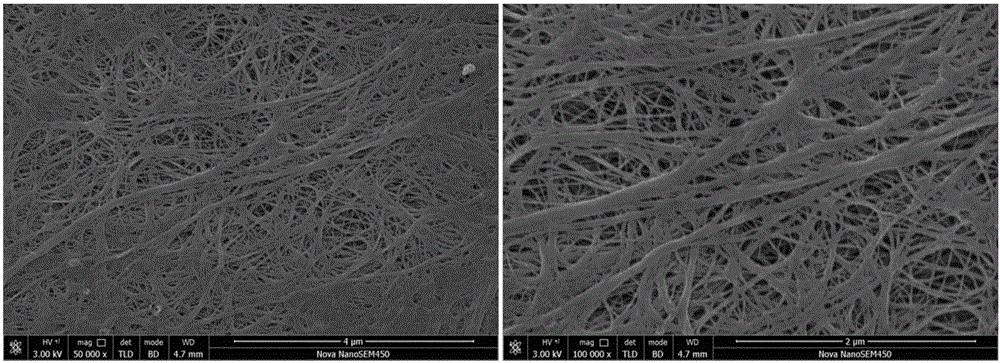

[0053] Two-way three-step stretching is carried out on the oil sheet by using a film bidirectional stretching device. The stretching temperature was 98° C., and the stretching speed was 1.5 mm / s. The first step of the three-step stretching process is stretching along the longitudinal direction to a strain of 3, the second step is stretching along the transverse direction to a strain of 5.5, and the third step is stretching along the longitudinal direction to a strain of 2. The parameters of the three-step stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com