A printed circuit board processing method, system and copper foil for processing

A technology of printed circuit boards and processing methods, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as endangering the health of workers, harming the health of operators, and inability to reuse them, and achieves a reduction in feces. The effect of avoiding the damage of toxic substances and reducing the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

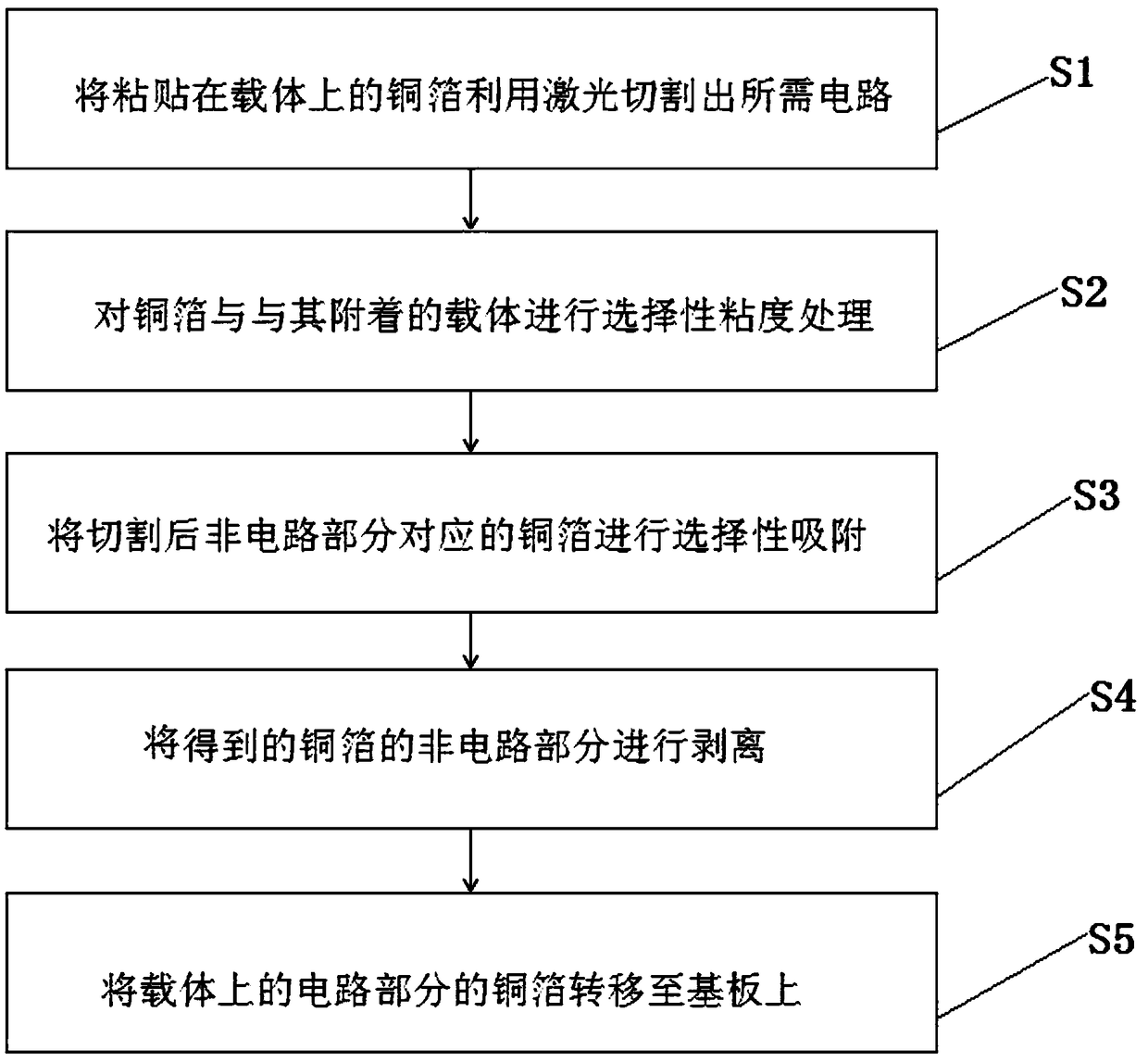

[0042] S5. Preparation of a printed circuit board, transferring the copper foil of the circuit part on the carrier to the substrate to obtain a printed circuit board. After the transfer is completed, use testing equipment to detect the circuit pattern of the printed circuit board on the substrate to ensure that the circuit pattern of the printed circuit board is correct.

[0043] Preferably, the selective viscosity treatment may specifically be to perform viscosity reduction treatment on the viscous substance between the copper foil corresponding to the non-circuit part and the carrier. In this embodiment, the physical viscosity treatment adopts water cooling treatment. The temperature of the water cooling treatment is 0-5 degrees. The water cooling treatment adopts a water cooling circulation device for cooling treatment, which includes a controller, a cooling circulation device and a water temperature sensor arranged inside the cooling circulation device. The cooling circula...

specific Embodiment 1

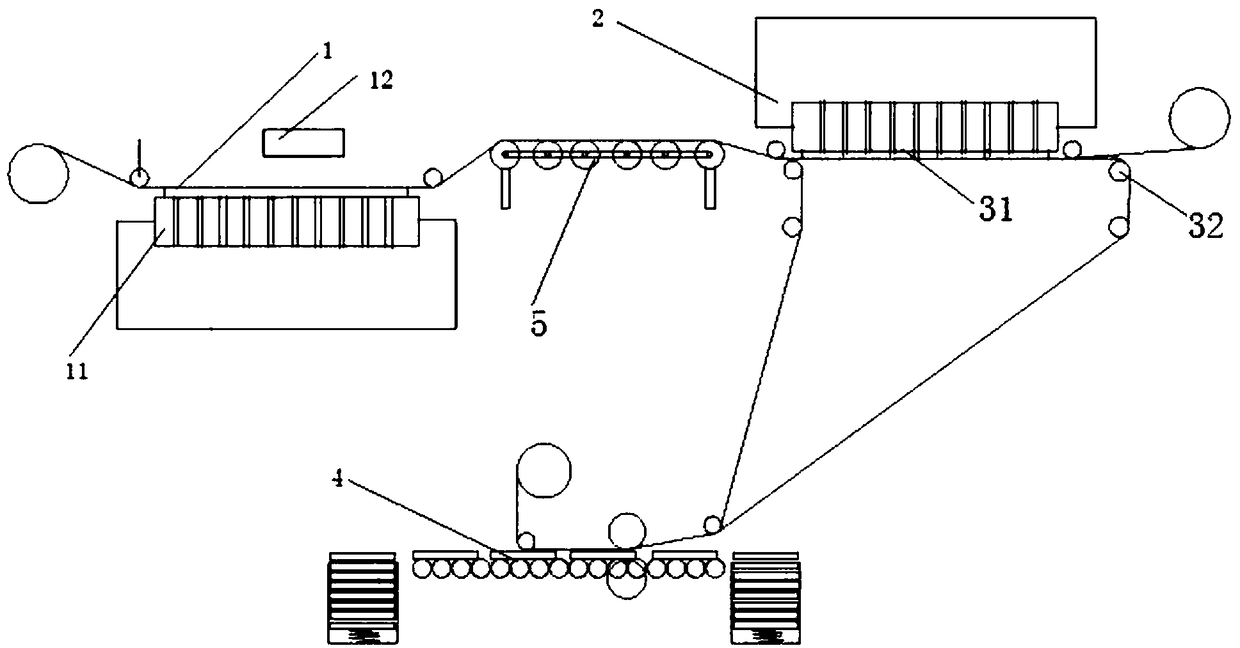

[0055] S1. Laser cutting: the copper foil pasted on the carrier is cut out of the required circuit by laser. Before laser cutting, the copper foil is first adhered to the carrier by means of an adhesive substance to obtain the copper foil to be cut.

[0056] S2. Perform selective viscosity treatment between the copper foil corresponding to the non-circuit part and the carrier. The viscosity between the copper foil corresponding to the non-circuit part and the carrier is different from the viscosity between the copper foil corresponding to the circuit part and the carrier, so as to facilitate the peeling of the copper foil of the non-circuit part.

[0057] S3. Selective adsorption: selectively adsorb the copper foil corresponding to the non-circuit part after cutting. The adsorption method can be electrostatic adsorption or negative pressure adsorption. The copper foil on the carrier corresponding to the non-circuit part is selectively adsorbed, so that it can be peeled off b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com