Cold-rolled and recrystallisation annealed flat steel product, and method for production thereof

A technique of crystallization annealing, flat steel, used in the manufacture of tools, coatings, furnace types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] The cold-rolled, roll-hardened flat steel products are supplied in the form of steel strips B1-B12 consisting of steel materials S1-S6 with the compositions given in Table 1.

[0121] These flat steel products are heat treated in different sizes in a continuously operating RTF type heat treatment furnace, then cooled to room temperature and subsequently temper rolled in-line.

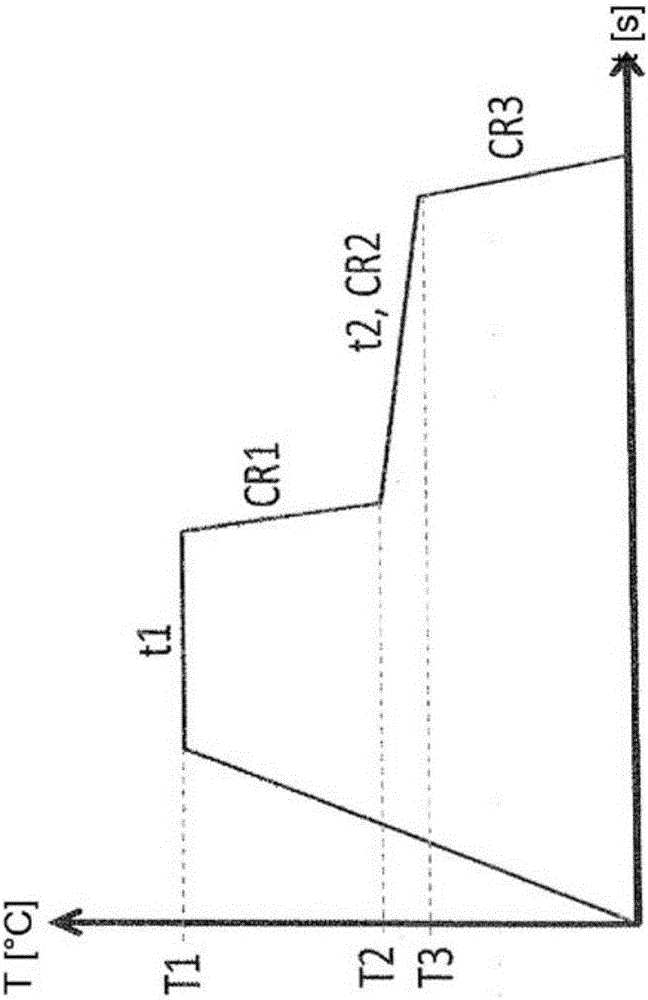

[0122] The heat treatment includes recrystallization annealing, in which the steel strips B1-B12 are heated to a holding temperature T1 of 835° C.±15° C., where they are held for a holding time of 60 s.

[0123] After recrystallization annealing, steel strips B1-B12 were overaged. For this, they were cooled from the holding temperature T1 to the overaging initiation temperature T2 of 530±15° C. at a cooling rate CR1 of 8.5° C. / s.

[0124] The steel strips B1-B12 are then cooled from this temperature to an overaging end temperature T3 of 280±15° C. over an overaging duration t2 of 302 seconds. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com