Combustion controlling device, combustion controlling method, combustion controlling program, and computer-readable recording medium

A control device, computing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

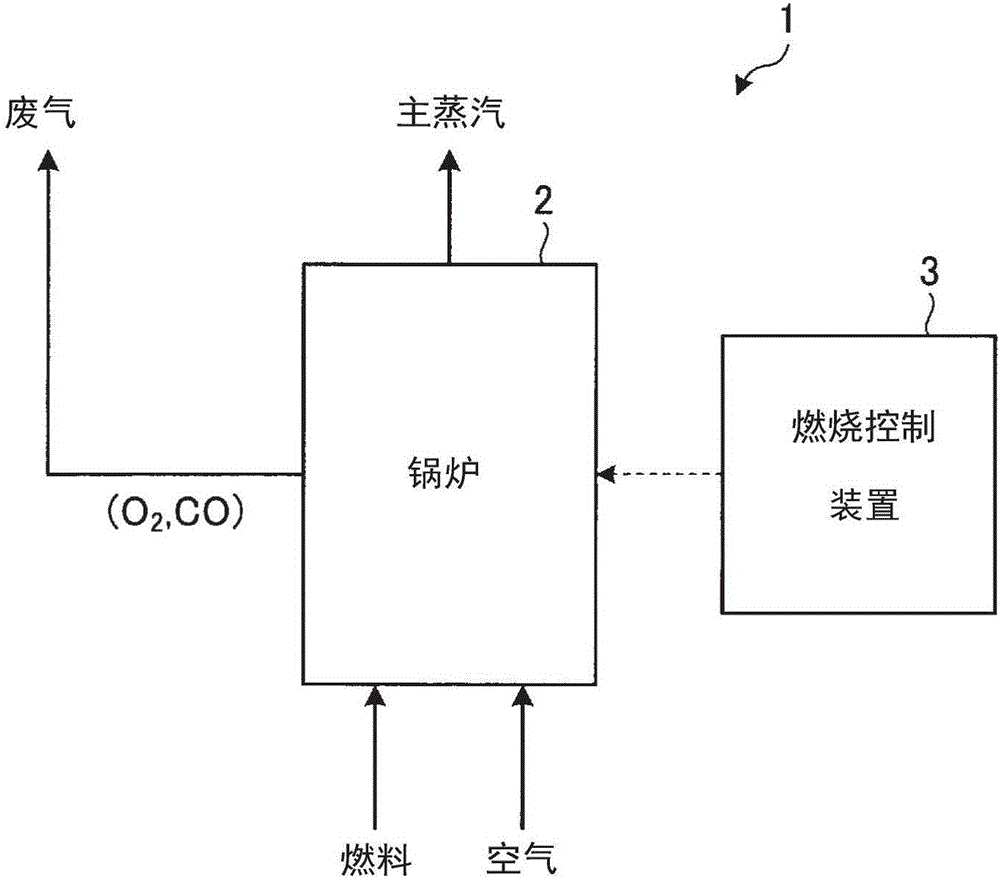

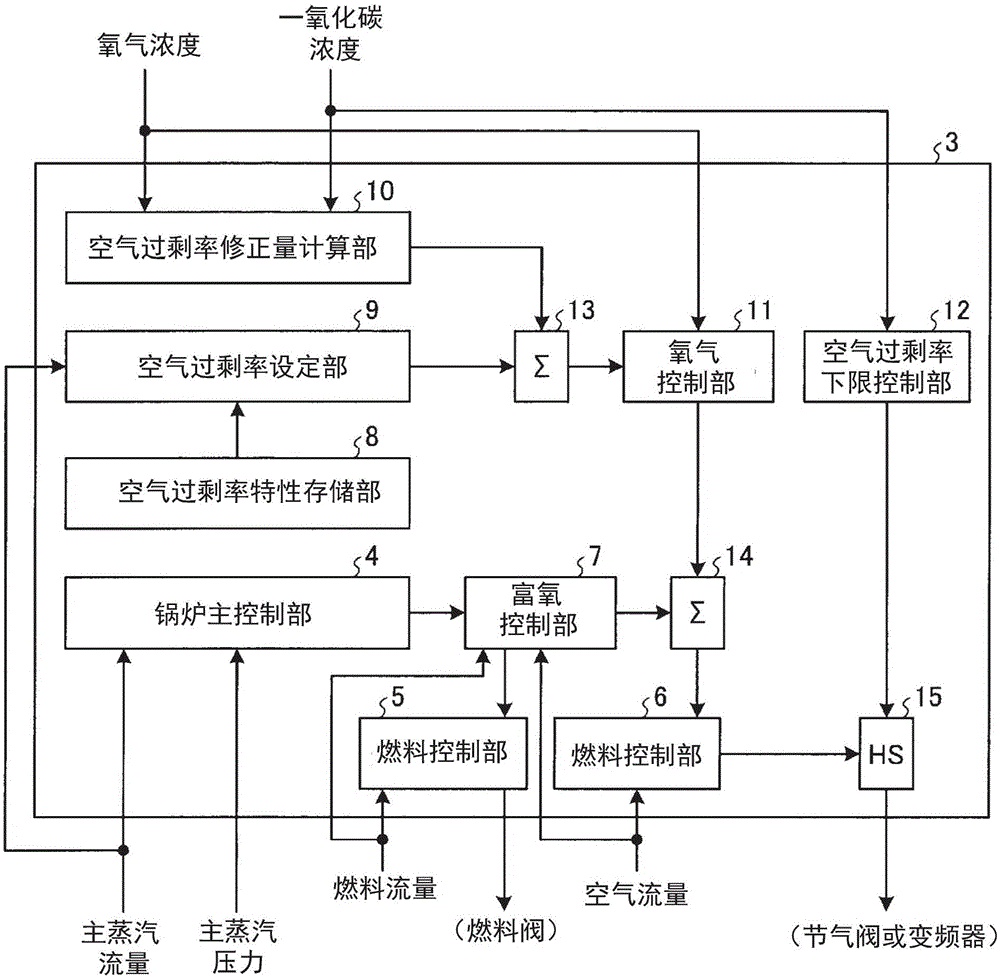

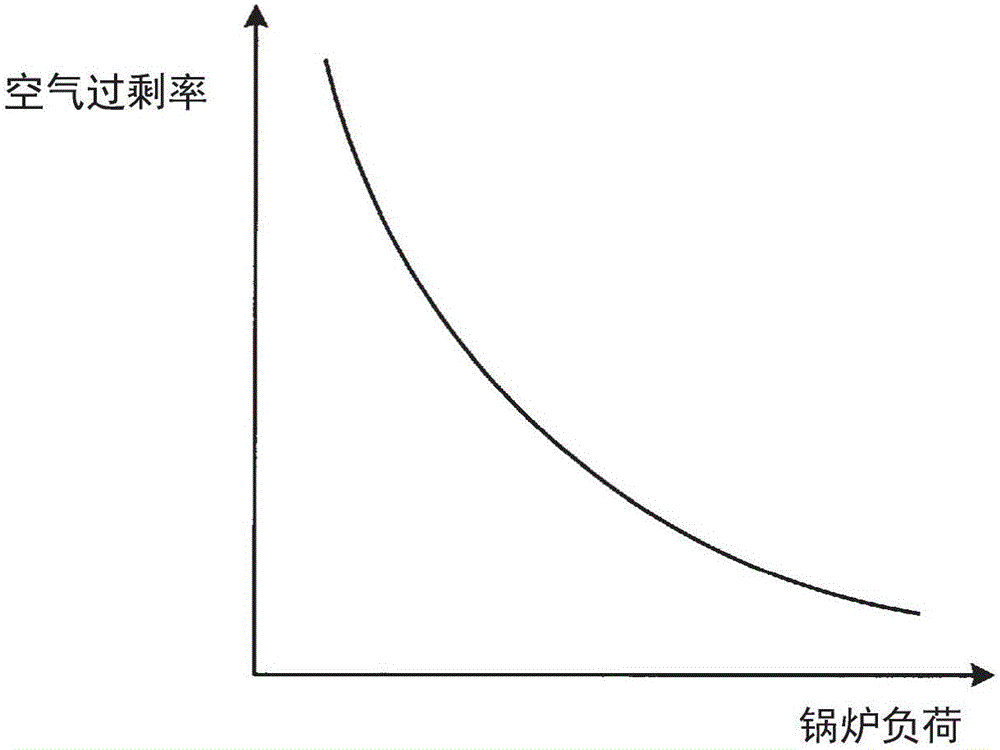

[0036] figure 1 It is a schematic configuration diagram showing a combustion system including the combustion control device according to Embodiment 1 of the present invention. The combustion system 1 shown in this figure includes: a boiler 2 that burns fuel to generate steam, and discharges waste gas (combustion gas) generated by fuel combustion through a discharge channel such as a chimney; and a combustion control device 3 that The device 3 controls the action of the combustion system 1 in a unified manner. The combustion system 1 has various measuring instruments for respectively measuring or setting the following items, namely: fuel flow rate and air flow rate flowing into the boiler 2; main steam flow rate and main steam pressure at the steam outlet of the boiler 2; exhaust gas at the exhaust gas outlet of the boiler 2 temperature; oxygen concentration and carbon monoxide concentration; and the temperature around the boiler 2. In addition, the air flow rate fed into th...

Embodiment approach 2

[0075] Embodiment 2 of the present invention is characterized in that the limit value of carbon monoxide emission (carbon monoxide limit value) that is set is considered according to conditions such as the place where the boiler is installed, and the carbon monoxide emission is kept constant without being affected by the load of the boiler. control. The setting of the carbon monoxide limit value can be realized by inputting the limit value into the combustion control device according to Embodiment 2 in advance by an installation device such as an input device, or by setting (or updating) by communication via a communication network. The configuration of the combustion control device according to the second embodiment is the same as that of the combustion control device 3 described in the first embodiment.

[0076] In Embodiment 2, the following formula (5) which does not include the incomplete combustion factor α is applied as the first heat loss calculation formula for obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com