A structural layout method of an ammonia uniform distribution device for flue denitrification

A technology with structural layout and uniform distribution, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as uneven distribution of ammonia gas, large amount of ammonia gas escape, and reduced denitrification efficiency, and achieve gas flow. Adjustable control, reduce ammonia escape rate, and benefit the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

[0017] Example:

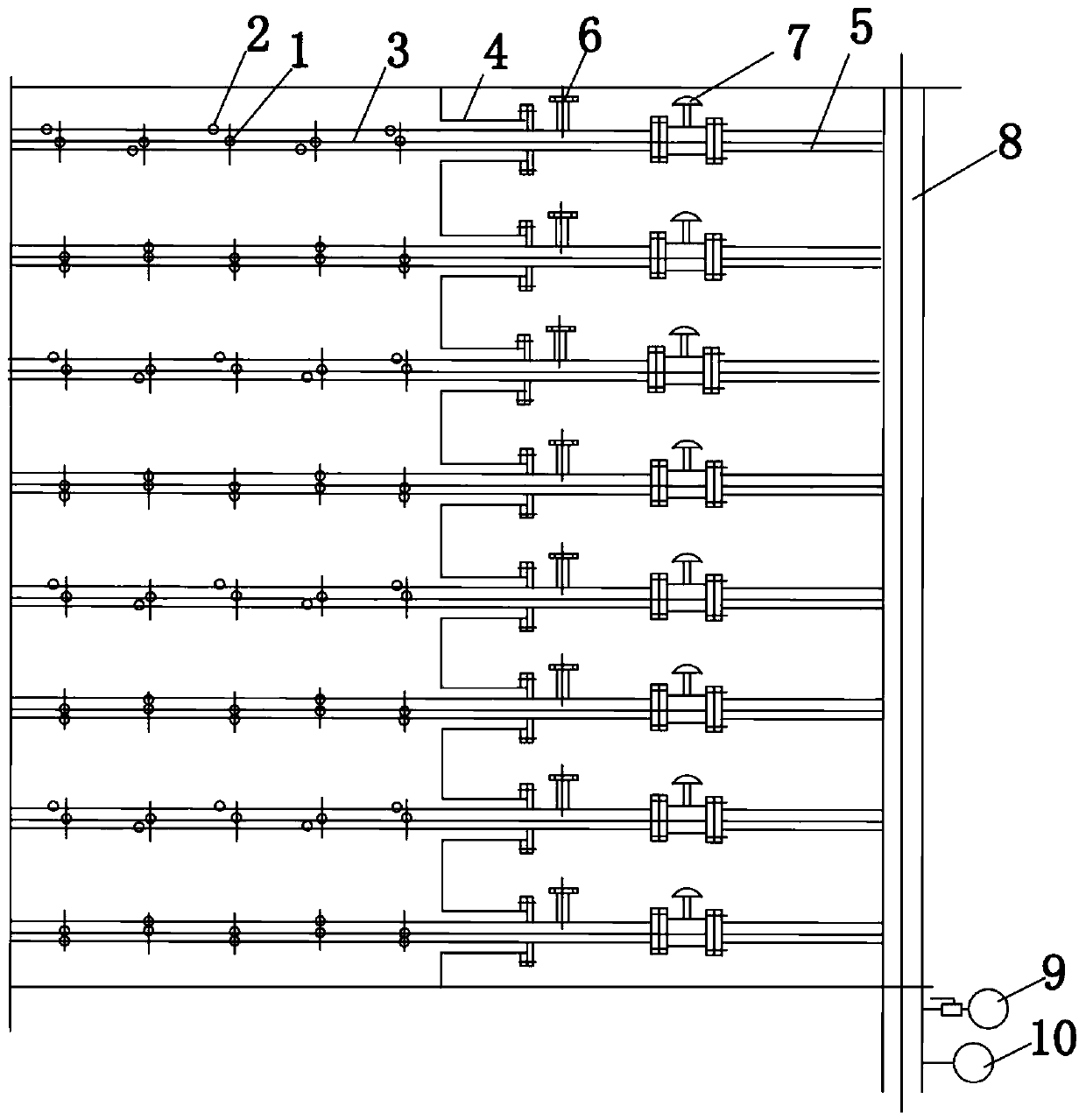

[0018] Such as figure 1 The structural layout method of an ammonia gas uniform distribution device for flue denitrification is shown, including ammonia gas nozzle 1, ammonia gas auxiliary nozzle 2, ammonia gas nozzle 3, installation sleeve 4, ammonia injection branch pipe 5, anti Blocking filter 6, manual adjustment valve 7, ammonia injection main pipe 8, ammonia pressure instrument 9, ammonia temperature instrument 10.

[0019] Firstly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com