A kind of preparation method of nanometer cu2o/ag/tio2-zeolite composite photocatalyst

A composite light and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as difficult separation, and achieve the effects of improving efficiency, high flexibility, and large adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

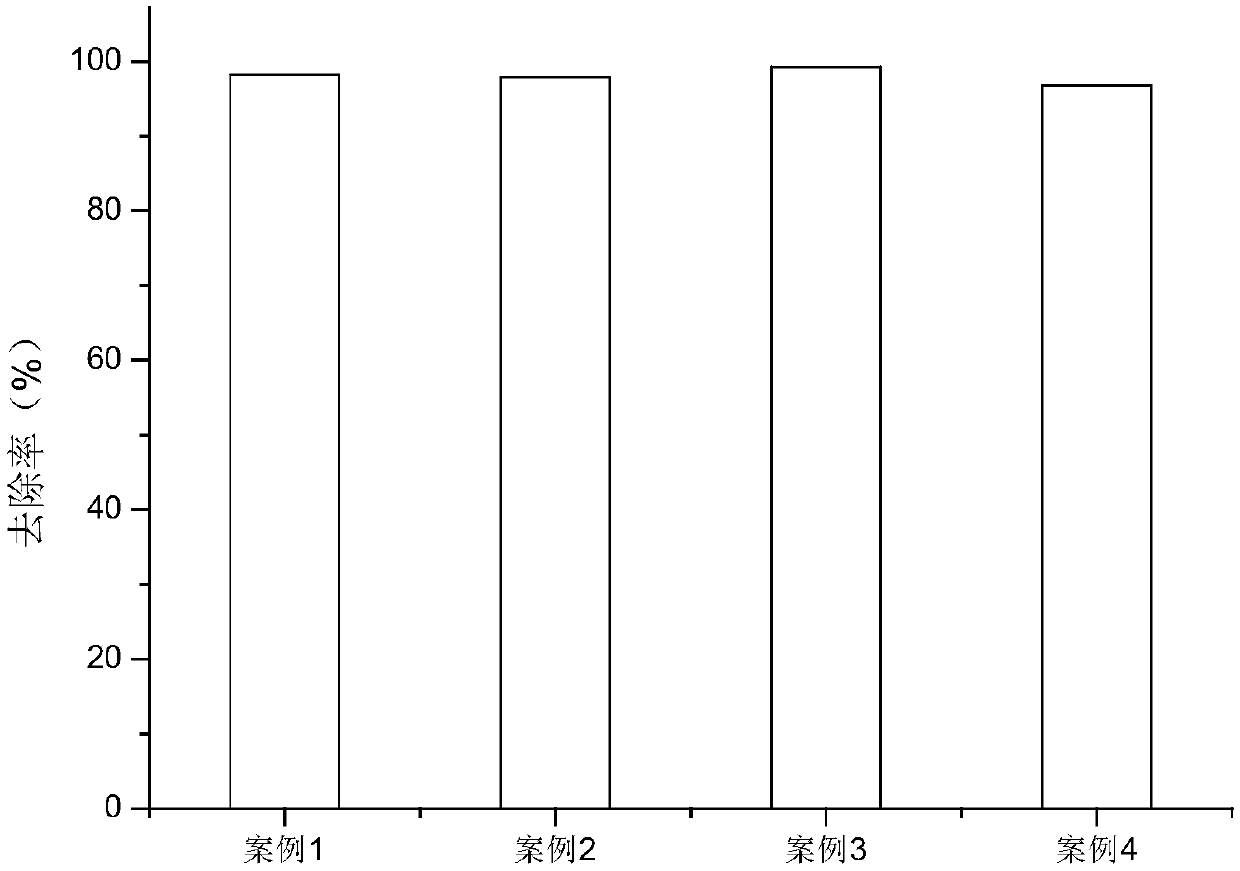

Examples

Embodiment 1

[0024] Nano-Cu in this embodiment 2 O / Ag / TiO 2 -The preparation method of zeolite composite photocatalyst specifically comprises the following steps:

[0025] (1) Disperse 5 g of artificial zeolite A in 50 mL of 10 mol / L NaOH solution, and stir at 100 ° C for 1 hour to form a zeolite precursor;

[0026] (2) Preparation of nano Cu 2 O, Ag and TiO 2 Mix the aqueous solution, and then fully mix with the zeolite precursor to prepare a mixed gel;

[0027] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0028] (4) The intermediate is separated, washed and dried, and then calcined at a high temperature to obtain the nano-Cu 2 O / Ag / TiO 2 - Zeolite composite photocatalyst.

[0029] In step (1), the amount of zeolite added in the alkali solution is: 0.01 g of zeolite is added to each milliliter of alkali solution.

[0030] Nano Cu in step (2) 2 O, Ag and...

Embodiment 2

[0035] Nano-Cu in this embodiment 2 O / Ag / TiO 2 -The preparation method of zeolite composite photocatalyst specifically comprises the following steps:

[0036] (1) Disperse 10 g of artificial zeolite X in 100 mL of 12 mol / L NaOH solution, and stir at 120 ° C for 3 hours to form a zeolite precursor;

[0037] (2) Preparation of nano Cu 2 O, Ag and TiO 2 Mix the aqueous solution, and then fully mix with the zeolite precursor to prepare a mixed gel;

[0038] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0039] (4) The intermediate is separated, washed and dried, and then calcined at a high temperature to obtain the nano-Cu 2 O / Ag / TiO 2 - Zeolite composite photocatalyst.

[0040] In step (1), the amount of zeolite added in the alkali solution is: 0.008g of zeolite is added per milliliter of alkali solution.

[0041] Nano Cu in step (2) 2 O, Ag and ...

Embodiment 3

[0045] Nano-Cu in this embodiment 2 O / Ag / TiO 2 -The preparation method of zeolite composite photocatalyst specifically comprises the following steps:

[0046] (1) Add the silicon source and the aluminum source into the alkali solution, mix thoroughly, and form a zeolite precursor under a certain temperature condition;

[0047] (2) Nano-Cu2 O, Ag and TiO 2 Add to the zeolite precursor and mix thoroughly to make a mixed gel;

[0048] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0049] (4) The intermediate is separated, washed and dried, and then calcined at a high temperature to obtain the nano-Cu 2 O / Ag / TiO 2 - Zeolite composite photocatalyst.

[0050] In step (1), the molar ratio of silicon source, aluminum source and alkali solution is 1:2:200. The silicon source is silica sol, and the aluminum source is pseudo-boehmite. Wherein, the alkalin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com