Method for treating water by using steel slag to catalyze ozone

A technology for water treatment and steel slag, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of poor pollutant removal effect, high catalyst cost and low reaction efficiency, etc. Achieving the effect of low price, high catalytic activity, and improved removal rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

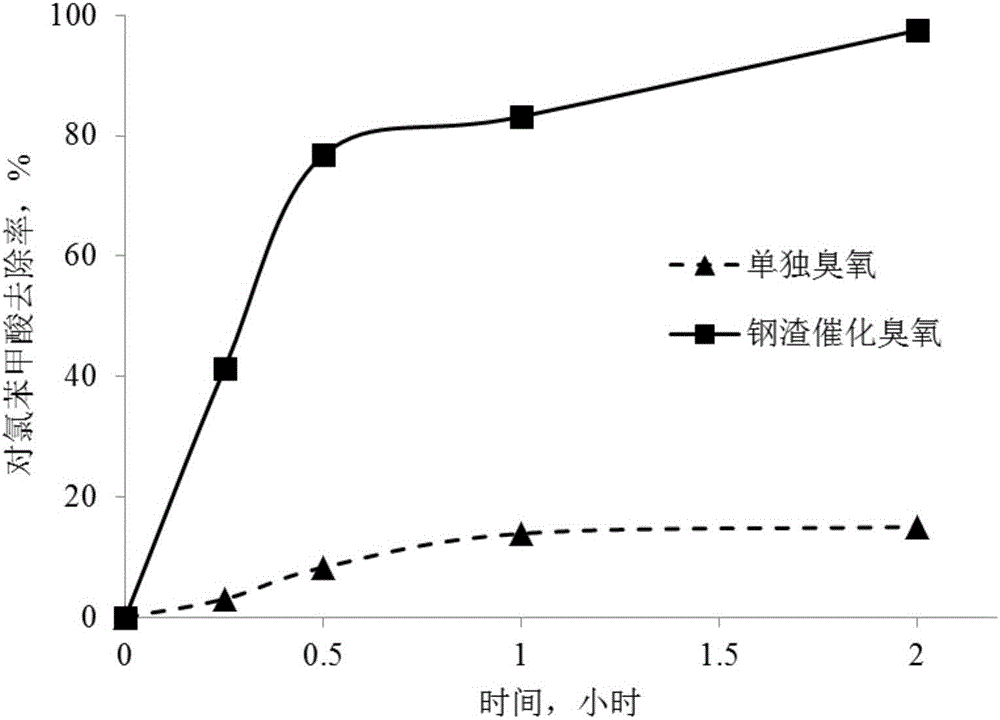

[0012] Add 20g / L steel slag to the reactor containing sewage (the concentration of p-chlorobenzoic acid is 50mg / L), and then introduce ozone for aeration. The ozone inlet concentration is 1mg / L, and the inlet flow rate is 0.2L / min, the residence time of wastewater in the reactor is 30min.

[0013] Depend on figure 1 The comparison of the p-chlorobenzoic acid removal rate curves of single ozonation and steel slag catalytic ozonation shows that the p-chlorobenzoic acid removal rate of single ozonation 2h is only 15%.

Embodiment 2

[0015] Add 50g / L steel slag to the reactor containing the water to be treated, and use ozone to aerate the water to be treated with the steel slag added. The ozone intake concentration is 30mg / L, and the intake flow rate is 0.6L / min. The residence time of the water to be treated in the reactor is 60min.

[0016] Depend on figure 1 The comparison of the p-chlorobenzoic acid removal rate curves of single ozonation and steel slag catalytic ozonation shows that the removal rate of p-chlorobenzoic acid can reach more than 82% after 1h of steel slag catalytic ozonation.

Embodiment 3

[0018] Add 50g / L steel slag to the reactor containing the water to be treated, and use ozone to aerate the water to be treated with the steel slag added. The ozone intake concentration is 15mg / L, and the intake flow rate is 1.0L / min. The residence time of the water to be treated in the reactor is 120min.

[0019] Depend on figure 1 The comparison of the p-chlorobenzoic acid removal rate curves of single ozonation and steel slag catalytic ozonation shows that the removal rate of p-chlorobenzoic acid can reach more than 98% after 2 hours of steel slag catalytic ozonation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com