A method for evaluating the performance of electroosmotic deep dewatering of excess sludge

A technology for deep dehydration and excess sludge, applied in dehydration/drying/thickening sludge treatment, weighing by removing certain components, etc., can solve problems such as heavy workload and inability to guarantee electroosmotic dehydration performance of excess sludge , to achieve the effects of simple estimation, reduced experimental workload, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

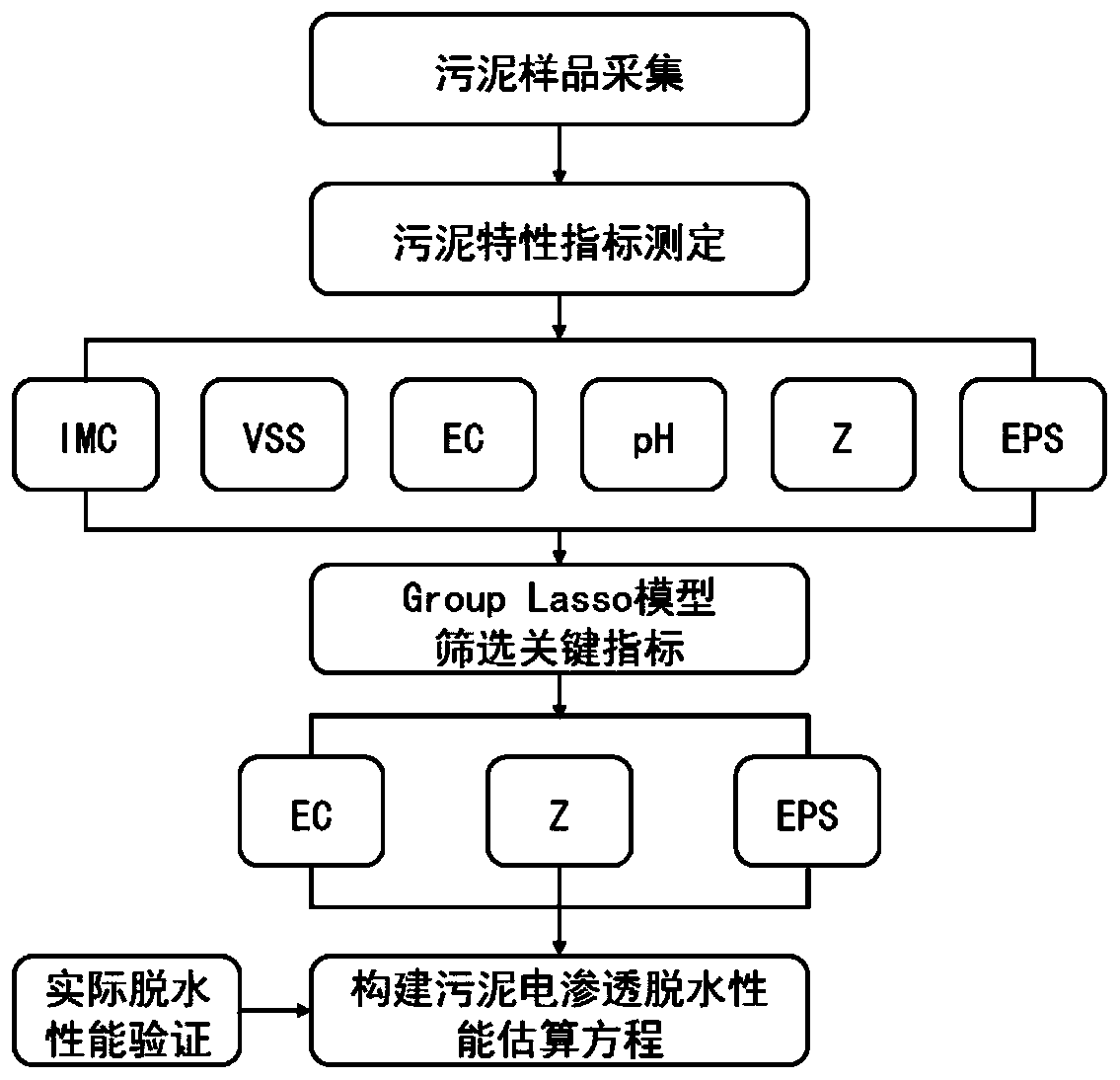

[0076] A kind of evaluation method of electroosmosis deep dewatering performance of excess sludge in this embodiment, such as figure 1 As shown, the specific steps are as follows:

[0077] S1: Collect remaining sludge samples and measure their IMC: Weigh 10g of sludge in a crucible, dry it in an oven at 105°C for 24 hours, then cool and weigh it, and measure IMC=81.80%.

[0078] S2: EC measurement: Add 25 mL of deionized water to 10 g of sludge sample, stir vigorously with a glass rod for 1-2 min, and after standing for 30 min, use a conductivity meter to measure the conductivity of the sludge supernatant to 1271 μs / cm.

[0079] S3: Z measurement: add 50mL deionized water to 0.5g sludge sample to make a suspension solution, and use HCl, NaOH solution to adjust the pH of the suspension, and KCl solution to adjust the conductivity of the suspension to make it the same as the original sludge , and then measured with a zeta potentiometer, the measured Z=-14.4mV.

[0080] S4: EPS...

Embodiment 2

[0084] A kind of evaluation method of electroosmosis deep dewatering performance of excess sludge in this embodiment, such as figure 1 As shown, the specific steps are as follows:

[0085] S1: Collect remaining sludge samples, and measure IMC: Weigh 10 g of sludge in a crucible, dry it in an oven at 105°C for 24 hours, then cool and weigh it, and measure IMC=80.90%.

[0086] S2: EC measurement: Add 25 mL of deionized water to 10 g of sludge sample, stir vigorously with a glass rod for 1-2 min, and after standing for 30 min, use a conductivity meter to measure the conductivity of the sludge supernatant to 1469 μs / cm.

[0087] S3: Z measurement: add 50mL deionized water to 0.5g sludge sample to make a suspension solution, and use HCl, NaOH solution to adjust the pH of the suspension, and KCl solution to adjust the conductivity of the suspension to make it the same as the original sludge , and then measured with a zeta potentiometer, the measured Z=-16.7mV.

[0088] S4: EPS mea...

Embodiment 3

[0092] A method for evaluating the performance of excess sludge electroosmosis deep dehydration in this embodiment, such as figure 1 As shown, the specific steps are as follows:

[0093] S1: Collect remaining sludge samples and measure IMC: Weigh 10 g of sludge in a crucible, dry it in an oven at 105°C for 24 hours, then cool and weigh it, and measure IMC=84.60%.

[0094] S2: EC measurement: Add 25 mL of deionized water to 10 g of sludge sample, stir vigorously with a glass rod for 1-2 min, and after standing for 30 min, use a conductivity meter to measure the conductivity of the sludge supernatant to 1138 μs / cm.

[0095] S3: Z measurement: add 50mL deionized water to 0.5g sludge sample to make a suspension solution, and use HCl, NaOH solution to adjust the pH of the suspension, and KCl solution to adjust the conductivity of the suspension to make it the same as the original sludge , and then measured with a zeta potentiometer, the measured Z=-18mV.

[0096] S4: EPS measurem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com