Self-adaption pulse detonation engine valve system driven by pressure

An engine valve, pulse detonation technology, applied in mechanical equipment, intermittent injection devices, etc., can solve problems such as difficult application, additional drive motor, work delay, etc., to avoid head leakage or air leakage, and improve service life. , to prevent the effect of negative thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples and drawings

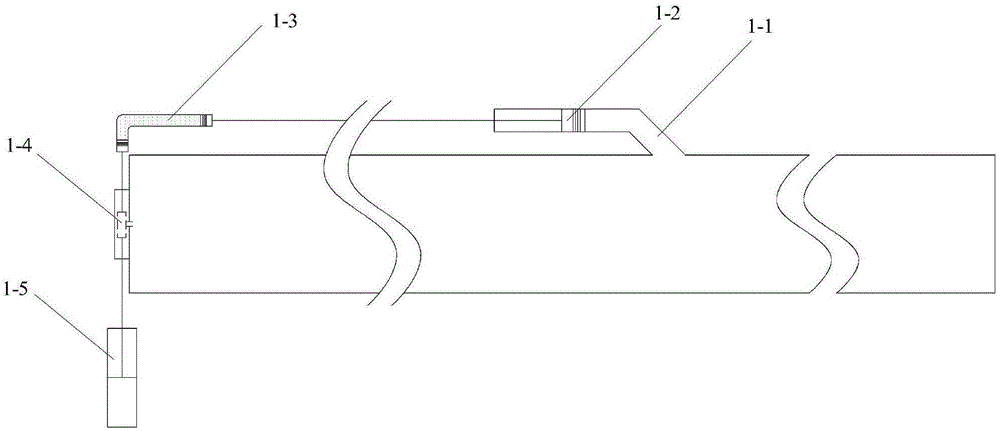

[0019] A pressure-driven adaptive pulse detonation engine valve system, each part of the component is in accordance with the attached figure 1 Assemble the structure shown in the attached figure 1 In the direction shown, the left side is the head of the detonation device, and the right side is the tail of the detonation device. The ignition device is installed on the head.

[0020] Since the sliding valves 1-4 are normally open, after the previous cycle ends, the PDE can normally intake air and inject fuel. After the filling process is over, the slow combustion wave generated by the ignition of the head generates a high-pressure detonation wave and back propagation wave through the DDT section. The detonation wave develops towards the tail and the back propagation wave propagates to the head. When the detonation wave propagates to the entrance of the drainage tube 1-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com