Vibration sensor tunnel on-line monitoring system based on wireless network transmission

A vibration sensor and wireless network technology, applied in the field of vibration monitoring systems, can solve the problems of vibration monitoring of difficult-to-rotate components, poor maintainability and scalability, and high deployment costs, achieving fast response time, fast processing, and low system resource occupancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

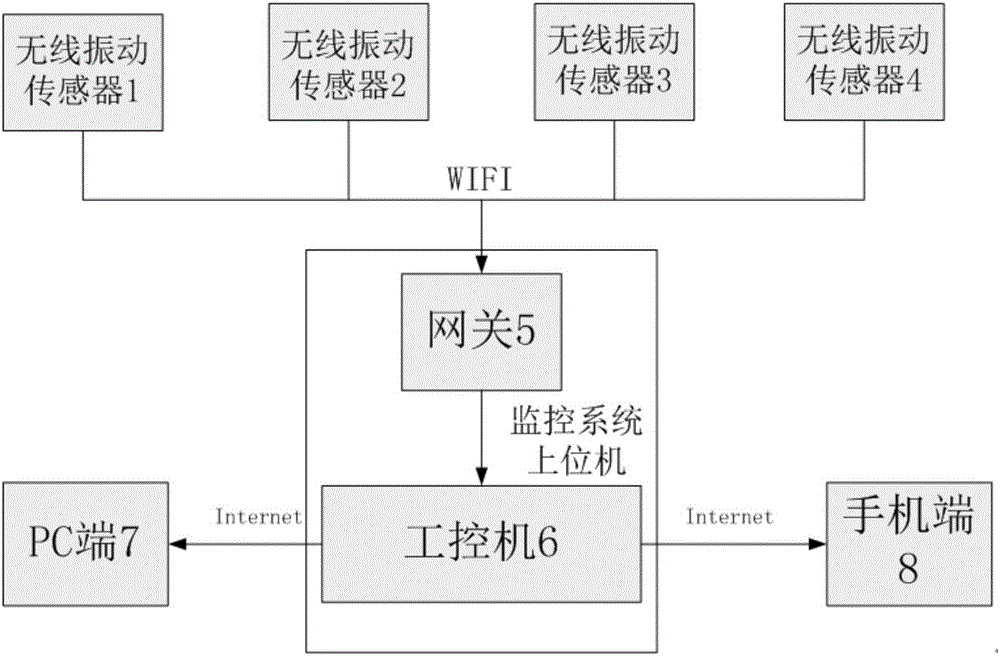

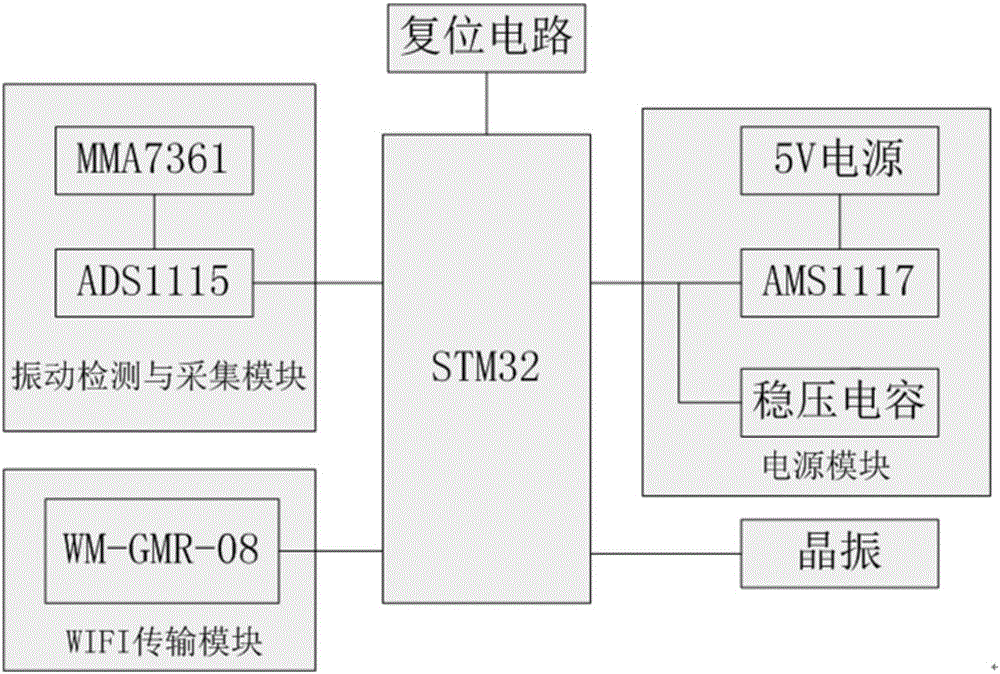

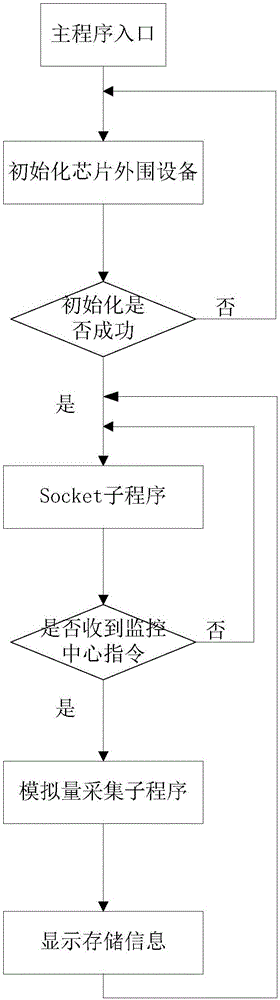

[0033] Such as figure 1 As shown, an online vibration sensor tunnel monitoring system based on wireless network transmission includes a monitoring center host system: a gateway 5, an industrial computer 6; a wireless vibration sensor; PC receiving software 7 and mobile phone receiving software 8. The wireless vibration sensor includes a first sensor 1 , a second sensor 2 , a third sensor 3 and a fourth sensor 4 . The wireless vibration sensor is placed on the tunnel in sequence in space, the wireless vibration sensor is directly connected to the gateway 5 through WIFI, and the gateway 5 is connected to the on-site industrial computer system 6 through a data line, wherein the gateway 5 and the industrial computer 6 Together they constitute the upper computer of the monitoring system. The wireless vibration sensor records the real-time vibration data at different positions of the tunnel in real time, sends the data to the gateway 5 through the wireless network, and transmits th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com