Gas energy-saving heater for fried food production line

A technology for fried food and production line, applied in the direction of oil/fat baking, etc., can solve the problems of high air pressure requirements of heat exchangers, low practical energy efficiency ratio, occupation of production space, etc., so as to reduce production space and equipment costs, and improve production. Safety and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

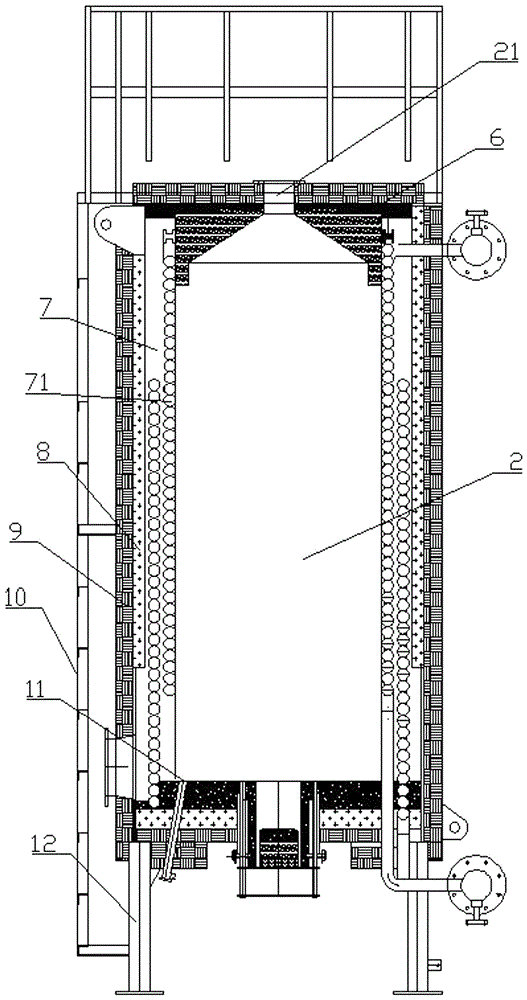

[0025] A gas-fired energy-saving heater for a fried food production line, such as figure 1 As shown, the furnace body 8 is included, and the furnace body 8 is vertically arranged. A leg 12 is provided at the bottom of the furnace body 8 , and the furnace body 8 is supported by the leg 12 . In addition, using the legs to support the furnace body 8 can reduce the influence of the high temperature inside the furnace body 8 on the ground.

[0026] A bottom cover 11 is arranged above the support, and the bottom cover 11 is connected to the bottom of the furnace body 8 by bolts. In order to ensure the sealing performance, a seal 6 is arranged between the furnace body 8 and the bottom cover 11. The seal 6 can be selected during implementation. Gasket. Seals are well established prior art.

[0027] Above the bottom cover 11, a top cover 1 located at the top of the furnace body 8 is arranged, and the top cover 1 is also connected to the furnace body 8 by bolts. In order to ensure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com