Method for connection of aluminum alloy and stainless steel special-section rotary components

A connection method, stainless steel technology, applied in welding equipment, metal processing equipment, welding/welding/cutting objects, etc., can solve the problem of inertia friction welding connection method without aluminum, aluminum alloy and steel, and ensure the welding quality and The effect of drawing size requirements, good joint quality, and satisfactory joint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention will be described in detail below with reference to the drawings and specific embodiments.

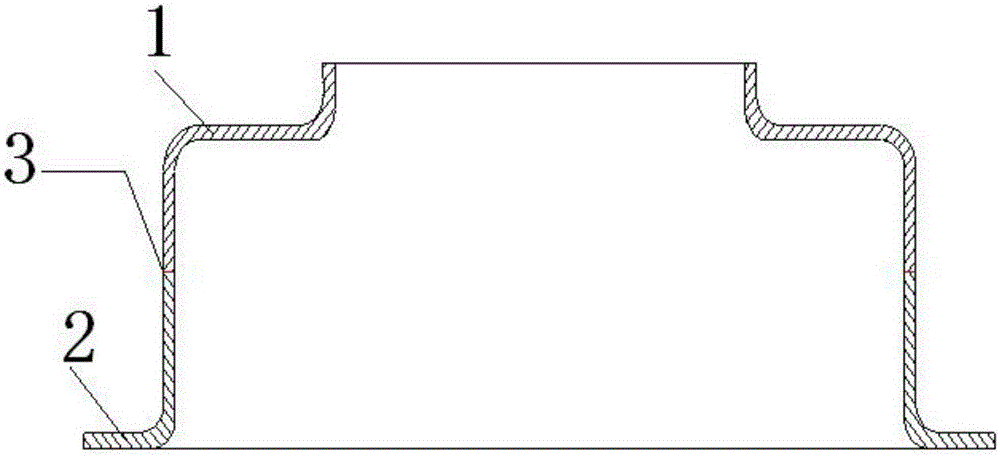

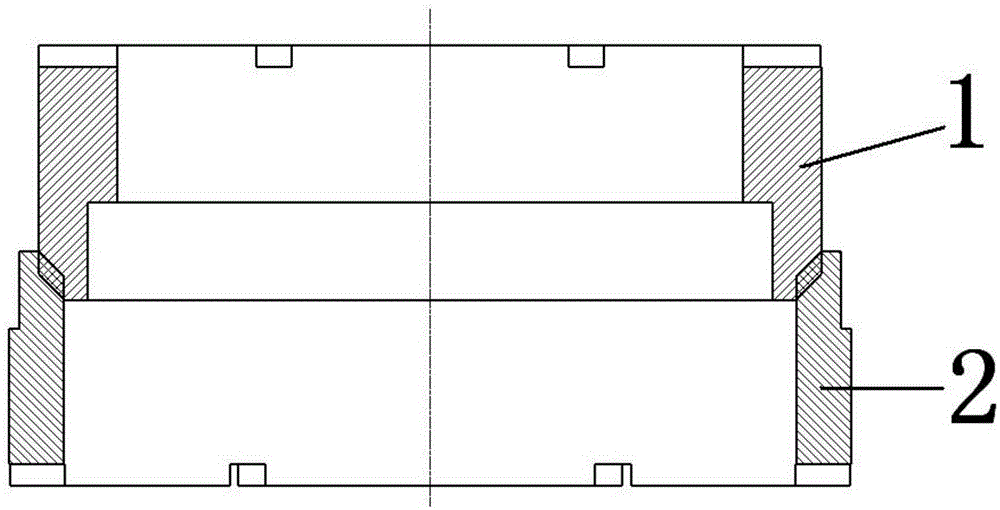

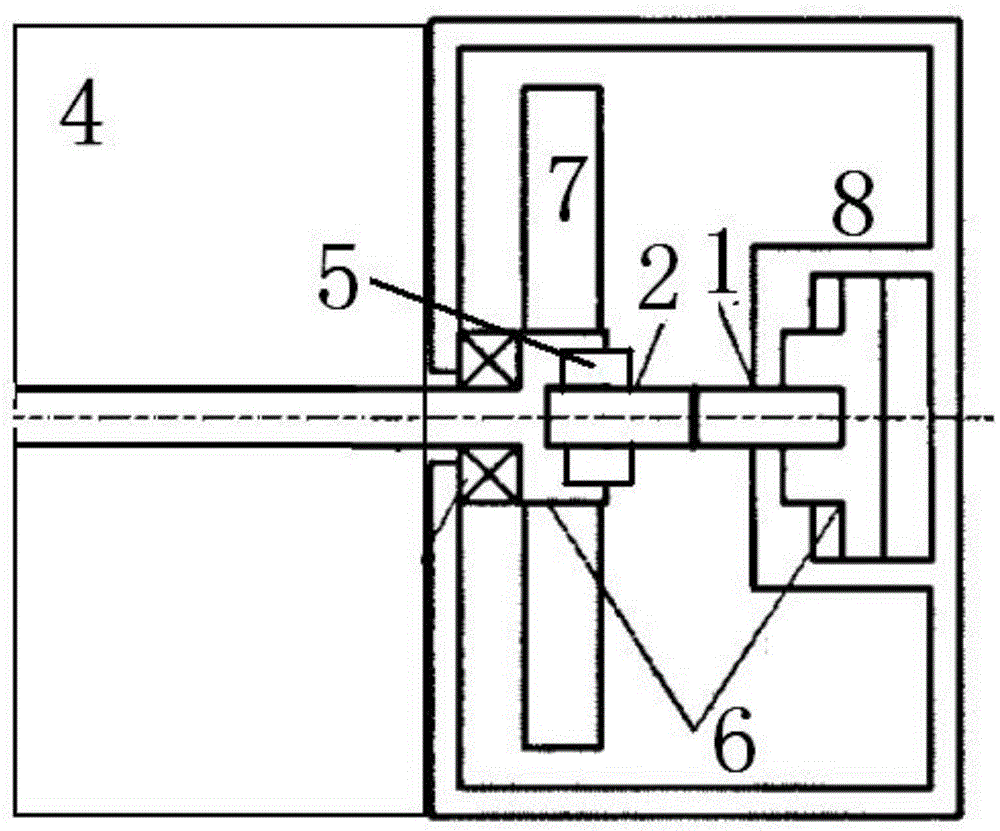

[0046] The present invention is a method for connecting aluminum alloy and stainless steel special profile revolving body components, which is suitable for inertial friction welding of aluminum alloy and stainless steel. The inertial friction welding of aluminum-steel outer cover joints in the transportation pipeline of aerospace launch vehicle is divided according to the process flow. For the three parts before welding, welding process, and after welding, each part has some key points, and these key points need to be comprehensively controlled to obtain good quality inertial friction welded joints. In this embodiment, the profile is figure 1 The double L-shaped structure shown, the diameter of the large end is Φ200mm, the size of the welded joint after processing, that is, the inertial friction welding process of 2219 aluminum alloy w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com