A kind of method for preparing superhydrophobic activated carbon

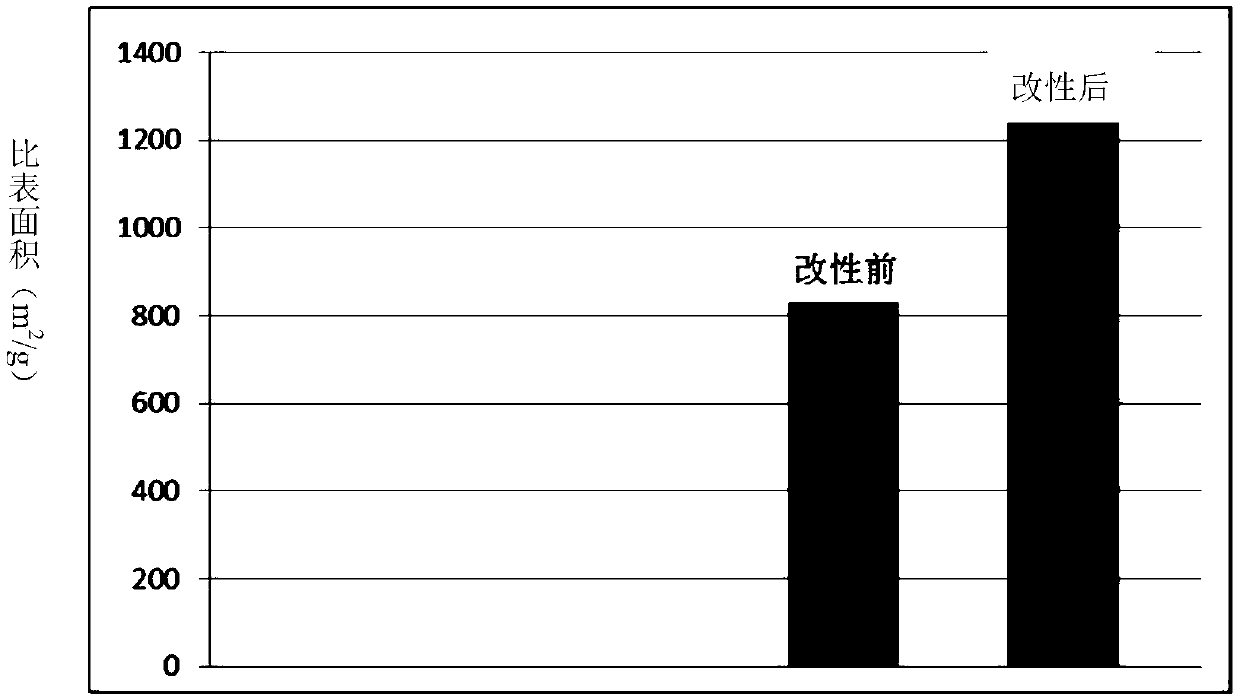

An activated carbon, super-hydrophobic technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of reducing the adsorption performance of activated carbon, high cost, complicated process, etc., to increase the amount of gas adsorption, increase the specific surface area, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the first step, add 100 mg of simethicone oil (Silicone elastomer base, Dow Corning 184) into 100 ml of heptane; simethicone is a simethicone whose terminal group is a hydroxyl group.

[0024] In the second step, add 10 mg of simethicone curing agent (silicone elastomer curing agent, Dow Corning 184) to the above solution, and keep stirring until uniform; One of cross-linking agents or cross-linking agents containing silicon hydrogen groups.

[0025] In the third step, 50g of activated carbon is added to the solution obtained in the second step, and after being completely absorbed, it is placed at room temperature to dry naturally;

[0026] In the fourth step, the obtained product is put into an oven and dried at a temperature of 150° C. for 2 hours.

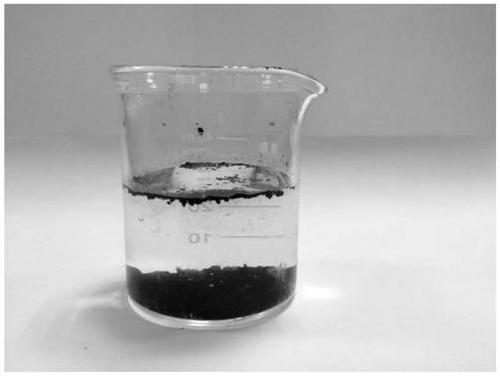

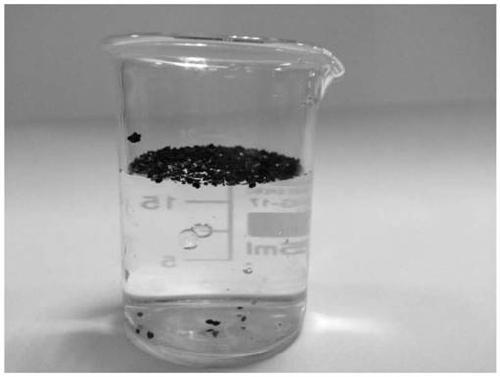

[0027] The fifth step is to compare the wetting of activated carbon before and after treatment. figure 1 For untreated activated carbon, it is obvious that when poured into water, there will be a large number of smal...

Embodiment 2

[0029] In the first step, add 10mg of simethicone (Silicone elastomer base) to 20ml of heptane;

[0030] In the second step, add 5 mg of simethicone curing agent (silicone elastomer curing agent) to the above solution, and keep stirring until uniform;

[0031] In the third step, 5g of activated carbon is added to the solution obtained in the second step, and after being completely absorbed, it is placed at room temperature to dry naturally;

[0032] In the fourth step, the obtained product is put into an oven and dried at 60° C. for 5 hours.

Embodiment 3

[0034] In the first step, add 100mg of simethicone (Silicone elastomer base) to 50ml of heptane;

[0035] In the second step, add 30 mg of simethicone curing agent (silicone elastomer curing agent) to the above solution, and keep stirring until uniform;

[0036] In the third step, 50g of activated carbon is added to the solution obtained in the second step, and after being completely absorbed, it is placed at room temperature to dry naturally;

[0037] In the fourth step, the obtained product is put into an oven and dried at 200° C. for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com