Water purifying system

A technology for water purification and pumping pipes, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve the problems of slow purification process, high purification cost, low dissolved oxygen, etc., achieve short purification cycle, low processing cost, The effect of high dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

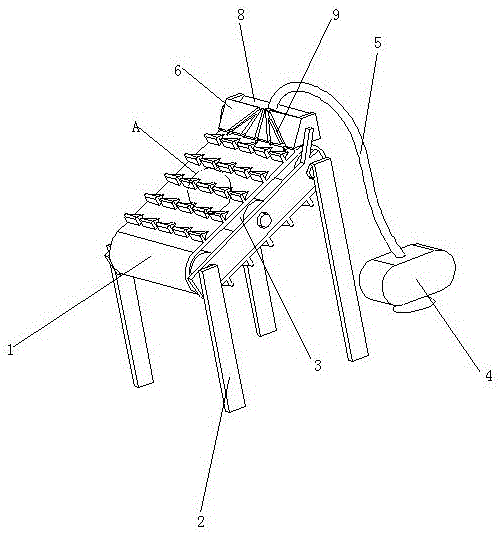

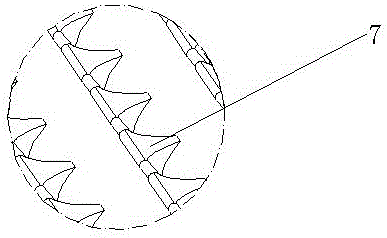

[0014] Such as figure 1 , 2 As shown, the present invention provides a water purification system, comprising a support frame 2, a plurality of support rollers 3, a belt 1, a motor, a suction pipe 5 and a submersible pump 4, the support roller 3 is installed on the support frame 2, and the belt 1 is wound around Outside the support roller 3, the motor drives the support roller 3 to rotate, and the belt 1 is installed obliquely. There is a dispersion tank 6 above the high point of the belt 1. The suction pipe 5 is connected to the submersible pump 4, and the outlet end of the suction pipe 5 is fixed to the dispersion tank. The top of the box 6, the top surface of the dispersion tank box 6 has a water tank 8, the front side of the dispersion tank is an inclined surface from top to bottom, and an umbrella-shaped diversion groove 9 is arranged on the inclined surface, and the upper end of the umbrella-shaped diversion groove 9 is located at In the middle of the tank 8, the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com