Coal slime and sludge drying upgrading device and process

A technology of sludge drying and drying medium, which is used in combined devices, dewatering/drying/concentrating sludge treatment, gas treatment, etc., which can solve the problem of poor particle size and quality of finished products, large floor space, and limited processing capacity of a single system. problems, to achieve the effect of small footprint, low system resistance, and accelerated water diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

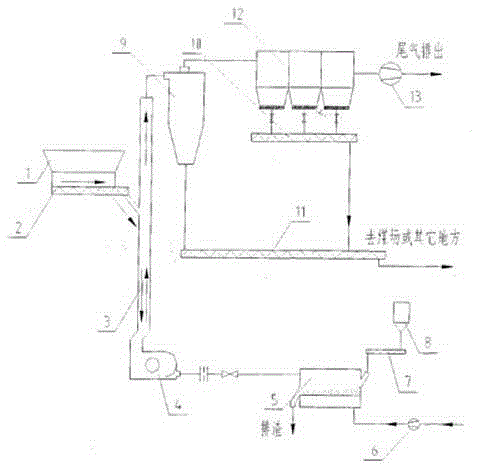

[0032] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

[0033] see figure 1 , the drying pipe 3 of this embodiment 1 adopts an equal cross-sectional structure, and the inlet of the high-moisture material to be dried is configured in the middle of the drying pipe 3 below the outlet of the drying pipe 3 and above the outlet of the material breaking device 4, so as to realize feeding in the middle; The inlet of the dry high-moisture material is connected to the discharge port of the feeder 2, the feed port of the feeder 2 is connected to the silo 1, the feeder 2 is a coal slime rotary cutter, and the smoke of the material breaking device 4 The gas inlet is arranged at the bottom of the material breaking device 4 and communicates with the flue gas outlet of the flue gas generator 5. The flue gas is fed from the bottom of the material breaking device 4, and the flue gas generator 5 is a chain furnace. in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com