High belite sulphoaluminate cement based self-leveling mortar

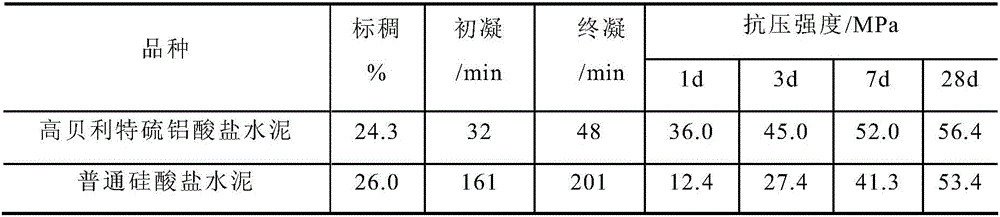

A special sulfoaluminate and self-leveling mortar technology is applied in the field of cement-based self-leveling mortar and high-belite sulfoaluminate cement-based self-leveling mortar, which can solve the difficulty in controlling the performance of self-leveling mortar and the preparation of self-leveling mortar. Complex process, high cost of self-leveling mortar preparation, to overcome conflict and compatibility problems, small dimensional change rate, smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh each powder raw material component according to the following weight: 740g of high belite sulfoaluminate cement; 100g of anhydrous gypsum, 290g of heavy calcium powder; 810g of river sand; 40g of latex powder; 7g of water reducer; 7g of defoamer; Cellulose ether 2g; tartaric acid 3g; lithium carbonate 1g, a total of 2000g. Pour the weighed materials into a mixer and mix them thoroughly until the bulk density of multiple samples taken at random does not change after measurement, and they are mixed uniformly to obtain high belite sulphoaluminate cement-based self-leveling mortar.

Embodiment 2

[0024] Weigh each powder raw material component according to the following weight: 600g of high belite sulfoaluminate cement; 100g of anhydrous gypsum, 300g of heavy calcium powder; 870g of river sand; 45g of latex powder; 9g of water reducer; 9g of defoamer; 3.5g of cellulose ether; 2g of tartaric acid; 1.5g of lithium carbonate, a total of 2000g. Pour the weighed materials into a mixer and mix them thoroughly until the bulk density of multiple samples taken at random does not change after measurement, and they are mixed uniformly to obtain high belite sulphoaluminate cement-based self-leveling mortar.

Embodiment 3

[0026] Weigh each powder raw material component according to the following weight: 800g of high belite sulfoaluminate cement; 120g of anhydrous gypsum, 240g of heavy calcium powder; 864g of river sand; 50g of latex powder; 8g of water reducer; 8g of defoamer; Cellulose ether 4g; tartaric acid 4g; lithium carbonate 2g, a total of 2000g. Pour the weighed materials into a mixer and mix them thoroughly until the bulk density of multiple samples taken at random does not change after measurement, and they are mixed uniformly to obtain high belite sulphoaluminate cement-based self-leveling mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com