Electrically expandable colloidal crystal thin film preparation method

A technology of colloidal crystals and thin films, which is applied in the field of preparation of colloidal crystal thin films, can solve the problems of difficult preparation of electro-expandable polymer materials, and achieve excellent electrochromic performance, wide discoloration range and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Embodiment 1: A method for preparing an electrically expandable colloidal crystal film in this embodiment is carried out in the following steps:

[0026] 1. Preparation of monodisperse polystyrene microspheres:

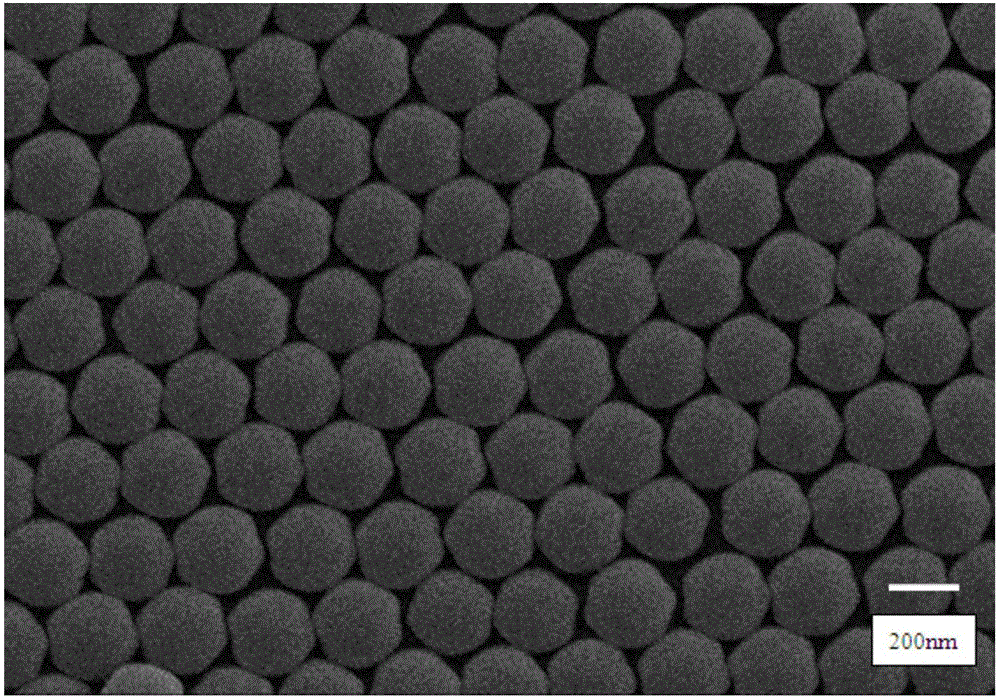

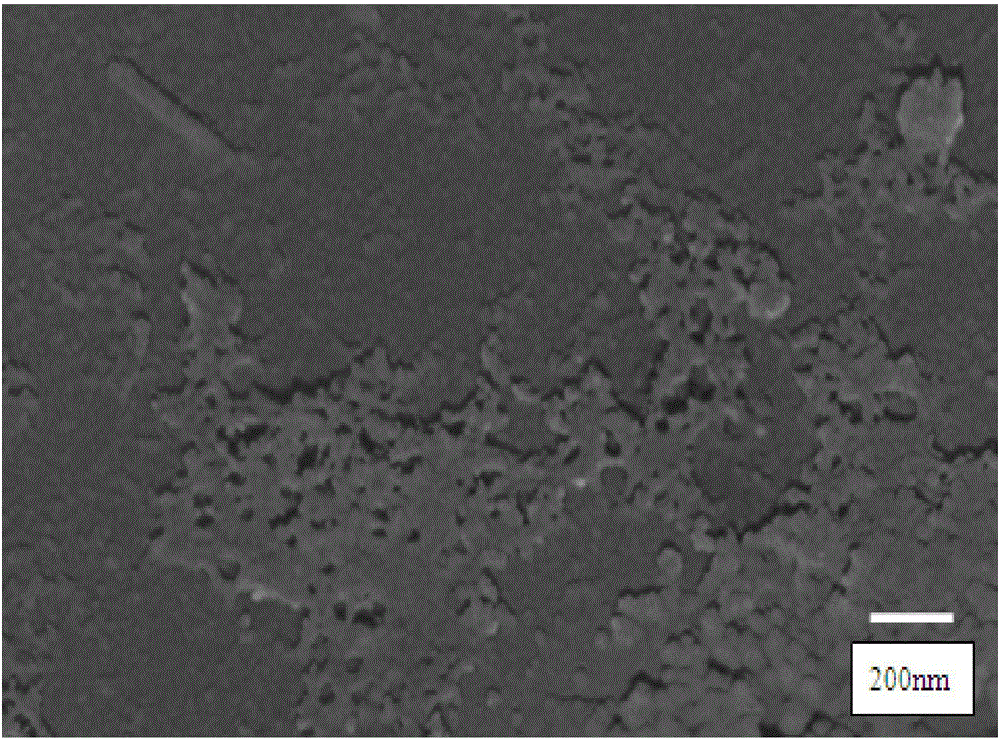

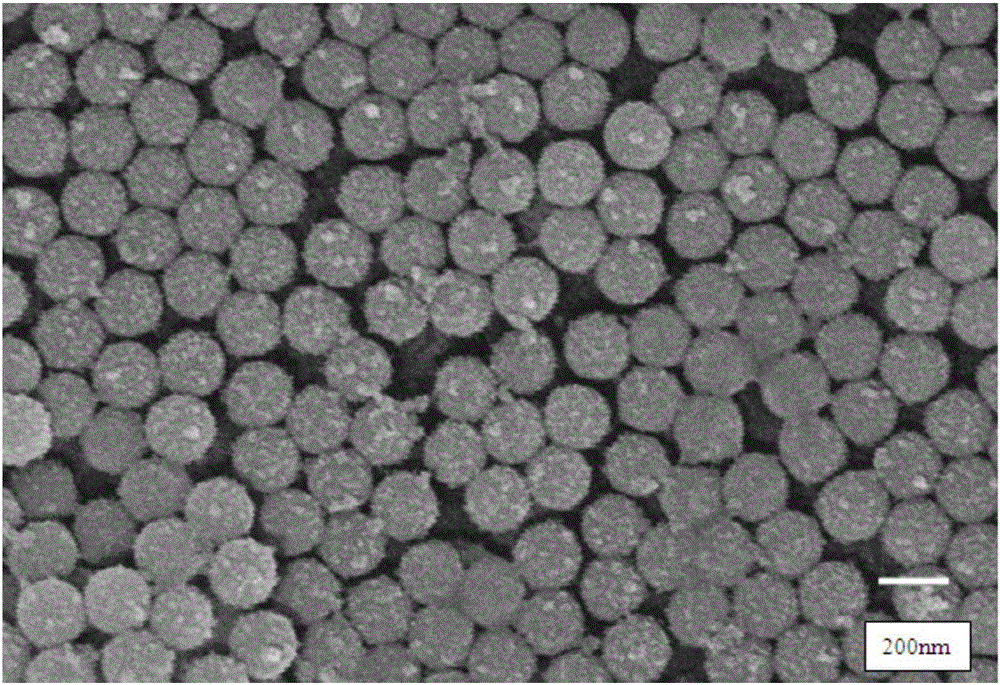

[0027] Add ultra-pure water into the three-port reactor, turn on the condensing circulating water, and use a mechanical stirrer to stir the ultra-pure water at the same time, and heat the three-port reactor to a temperature of 50°C with a super constant temperature water bath at a speed of 300rpm-3000rpm ~100°C, then pass nitrogen into the three-port reactor to remove the oxygen in the system, add styrene into the three-port reactor, then add potassium persulfate solution with a mass percentage of 1% to 50%, and react for 12h to 48h. Obtain monodisperse polystyrene microspheres with a particle size of 200nm to 1000nm;

[0028] The volume ratio of described styrene and ultrapure water is 1:(30~100); The volume ratio of described styrene and mass percentage is 1...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of styrene and ultrapure water described in step 1 is 1:(50-100). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Specific embodiment three: what this embodiment is different from one of specific embodiment one or two is: the volume ratio of the potassium persulfate solution of 1%~50% is 1:( 0.02~0.1). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com