A chemical vapor deposition device

A technology of chemical vapor deposition and air intake chamber, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., to prevent the deposition of reactants, reduce equipment maintenance costs, and reduce diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

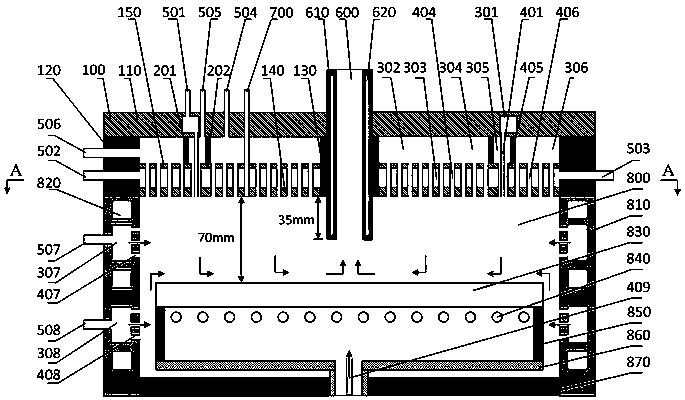

[0020] Such as figure 1 As shown, the present invention provides a chemical vapor deposition apparatus, including: a reaction chamber 800 and a shower head 100 located at the top of the reaction chamber 800 .

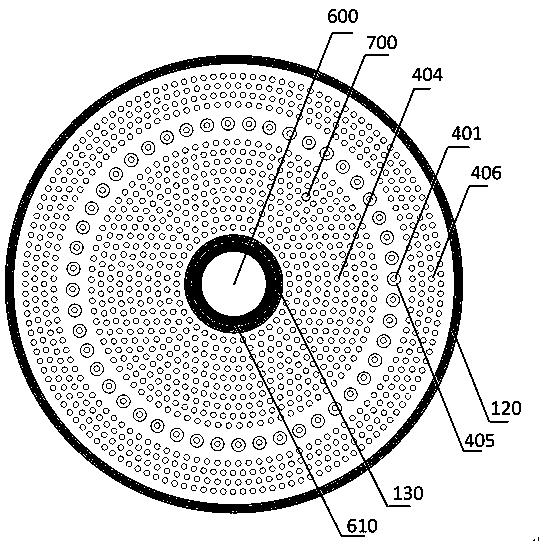

[0021] The shower head 100 includes a hollow cylinder composed of a top plate 110, an outer side wall 120, an inner side wall 130 and a bottom plate 140. An upper air inlet chamber 301 is arranged inside the top plate 110. The inside of the hollow cylinder is divided into two parts by a middle plate 150. An independent and mutually sealed part, from top to bottom is the lower air intake cavity 302 and the cooling cavity 303, wherein the lower air intake cavity 302 is divided into three parts by two vertical circular partition walls 201 and 202, along the radial direction From the center to the outside, there are an inner and lower air intake cavity 304 , a middle and lower air intake cavity 305 and an outer and lower air intake cavity 306 . The air inlet 501 of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com