A kind of anti-freezing method of gas path

A gas circuit and heating chamber technology, applied in earthwork drilling, wellbore/well components, fluid pressure actuators, etc., can solve problems such as slowing down of air control transmission speed, lower drilling rig efficiency, and easy freezing of air control components , to achieve the effect of preventing condensation and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

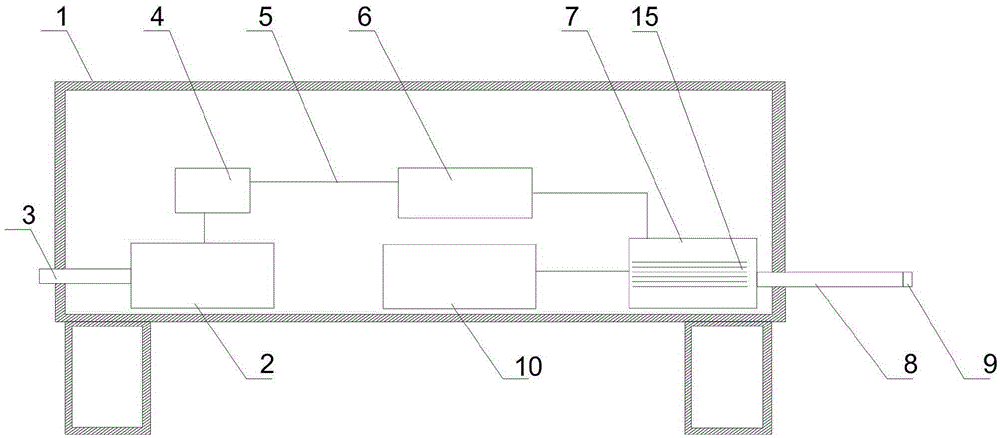

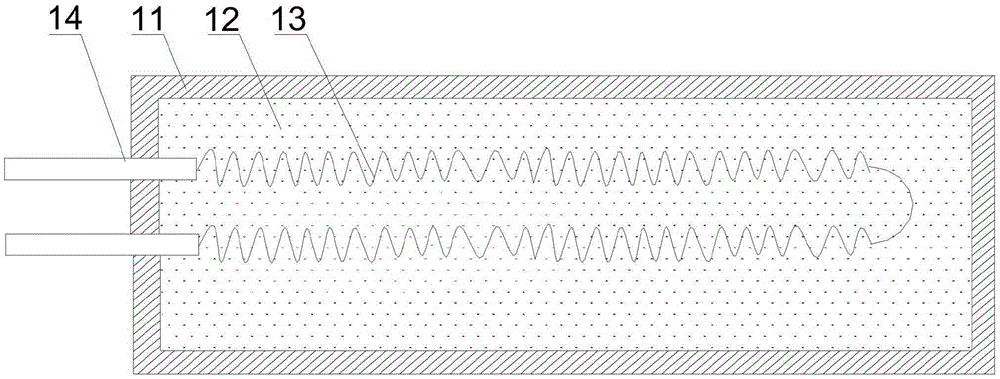

[0020] Such as figure 1 and figure 2 As shown, the present invention first antifreezes the gas path of the oil drilling rig through the antifreeze mechanism in a low temperature environment. The cabinet of the antifreeze mechanism can be arranged outdoors together with the rig. It is sent to the fan, and the compressed air becomes pure and dry after being finely filtered by the water separator. The filtered air is sent to the heating chamber to be heated by the heating pipe, and then enters the external drilling rig air circuit through the air outlet pipe. , the air control components can be reheated, so that each air control component can maintain a temperature above 0°C in a low temperature environment without freezing and freezing; wherein the antifreeze mechanism includes a cabinet 1, an air compressor 2, a fan 4, a heating Chamber 7, air inlet pipe 3 and air outlet pipe 8, air compressor 2, fan 4 and heating chamber 7 are all arranged in cabinet 1, fan 4 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com