Preparation method of low-carbon steel sample for electron back scattering diffraction analysis

A technology of electron backscattering and low-carbon steel, which is applied in the preparation of samples for electron backscattering diffraction analysis and the preparation of low-carbon steel samples for electron backscattering diffraction analysis, which can solve the problems of poor sample reproducibility and low calibration rate , to achieve the effect of simple operation, avoiding poor reproducibility and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

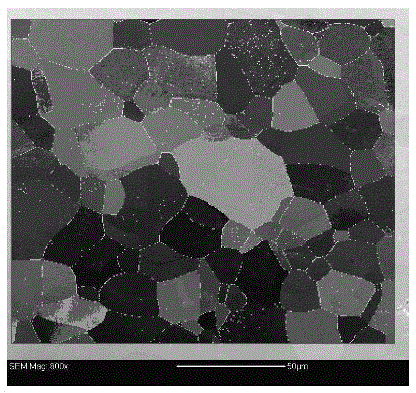

[0030] The steel plate used in Example 1 is a low-carbon IF steel with a thickness of 2.0 mm, and the cross-section of the sample is analyzed by EBSD microstructure. The equipment for EBSD analysis was FEI Quanta450 scanning electron microscope equipped with Oxford EBSD accessories.

[0031] A method for preparing a low-carbon steel sample for electron backscattered diffraction analysis, comprising the steps of:

[0032] 1) Use a metallographic special cutting machine to cut a steel plate with a surface size of 15mm×15mm, and the surface to be analyzed is a cross section, and use the Mecapress3 mosaic machine steel plate of France Press to make a mosaic sample;

[0033] 2) Place the mosaic sample on the Buehler phoenix4000X semi-automatic dynamic grinding machine, and mechanically grind the mosaic sample. The grinder uses sandpaper with a particle size of 180 mesh, 400 mesh, 800 mesh, and 1200 mesh to grind the mosaic sample for 20 minutes respectively. The speed is 100RPm, t...

Embodiment 2

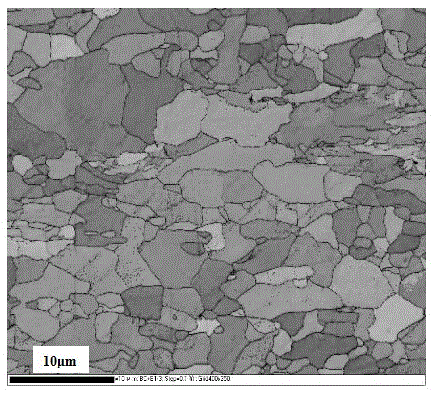

[0039] The steel plate in Example 2 is a low-carbon alloy steel HR700F with a thickness of 5.0 mm, and the cross-section of the sample is analyzed by EBSD microstructure. The equipment for EBSD analysis was FEI Quanta450 scanning electron microscope equipped with Oxford EBSD accessories.

[0040] A method for preparing a low-carbon steel sample for electron backscattered diffraction analysis, comprising the steps of:

[0041] 1) Use a metallographic special cutting machine to cut out a steel plate with a surface size of 15mm×15mm, and the surface to be analyzed is a cross section, and use the Mecapress3 mosaic machine steel plate of France Press to make a mosaic sample;

[0042] 2) Put the mosaic sample on the Buehler phoenix4000X semi-automatic grinding machine, and mechanically grind the mosaic sample. The grinder uses sandpaper with a particle size of 180 mesh, 400 mesh, 800 mesh, and 1200 mesh to grind the mosaic sample for 30 minutes respectively. The speed is 200RPm, th...

Embodiment 3

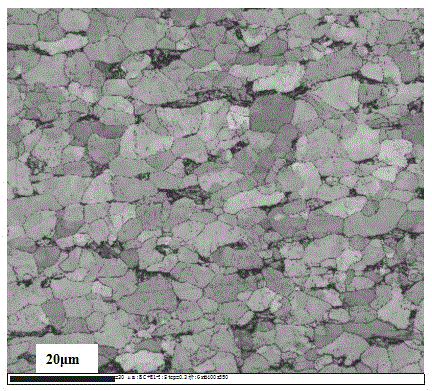

[0048] The steel plate in Example 3 is a low-carbon microalloy dual-phase steel DP600 with a thickness of 4.0 mm, and the cross-section of the sample is analyzed by EBSD microstructure. The equipment for EBSD analysis was FEI Quanta450 scanning electron microscope equipped with Oxford EBSD accessories.

[0049] A method for preparing a low-carbon steel sample for electron backscattered diffraction analysis, comprising the steps of:

[0050] 1) Use a metallographic special cutting machine to cut a steel plate with a surface size of 15mm×15mm, and the surface to be analyzed is a cross section, and use the Mecapress3 mosaic machine steel plate of France Press to make a mosaic sample;

[0051] 2) Place the mosaic sample on the Buehler phoenix4000X semi-automatic dynamic grinding machine, and mechanically grind the mosaic sample. The grinder uses sandpaper with a particle size of 180 mesh, 400 mesh, 800 mesh, and 1200 mesh to grind the mosaic sample for 20 minutes respectively. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com