Grain multistep sorting combined cleaning sieve

A technology for grain and fractionation, which is applied in the direction of filtering, solid separation, and separation of solids from solids with airflow, to achieve the effects of ensuring screening quality, large output, and reducing working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

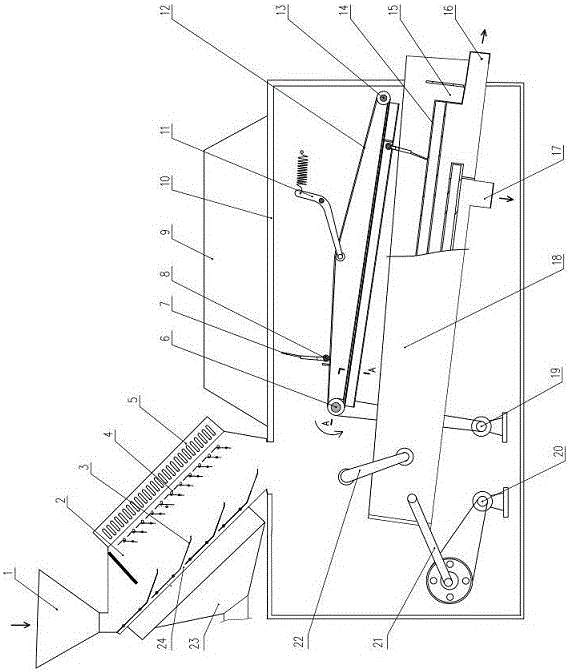

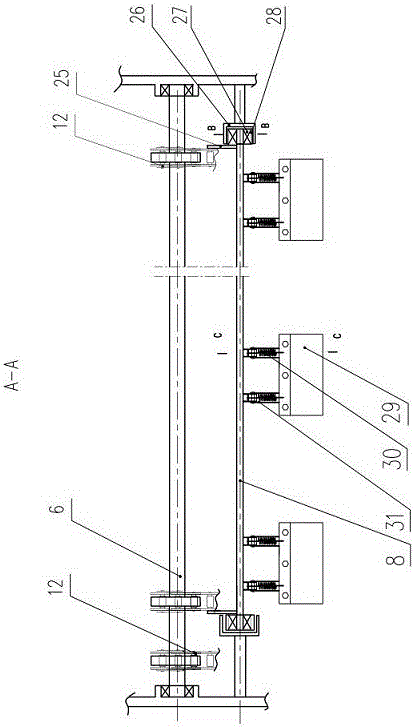

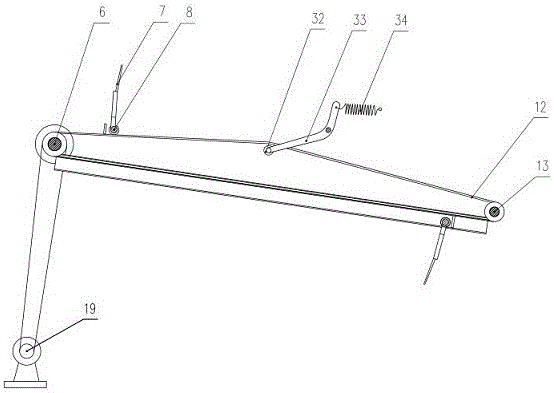

[0030] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0031] The present invention is a combination cleaning screen for multi-stage sorting of grain, which is composed of three parts: a screen box 18, a grain cleaning device 2 and a chain-type brush plate mechanism. The sieve box 18 is an integral sieve box, which is welded by multi-layer sieve plates 14 with different apertures, and the lower end is provided with a large miscellaneous outlet 15, a small miscellaneous outlet 17 and a grain net object outlet 16. Integral sieve box 18 is suspended in the body 10 by four cantilever arms 22. Driven by motor 20 and eccentric connecting rod 21, it can swing in the body 10 to carry out gravity screening to grain. The grain cleaner 2 is arranged on the top of the sieve box 18, and the feeding port 1 is located at the upper port of the grain cleaner 2. See figure 1 .

[0032] The body 10 is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com