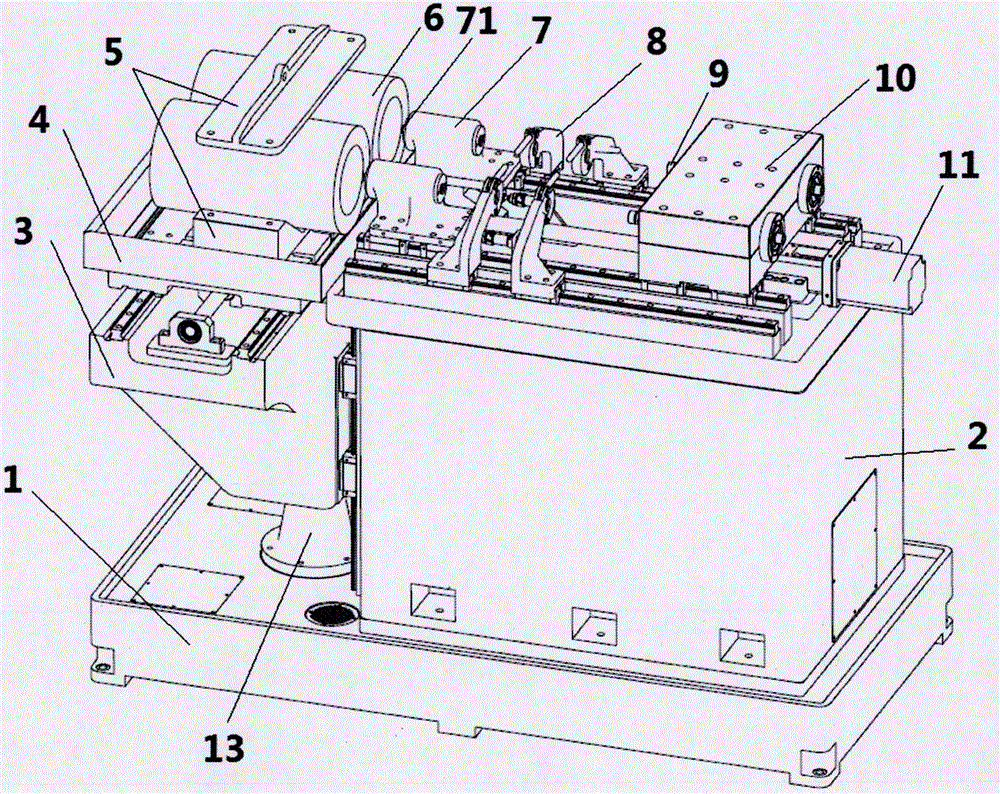

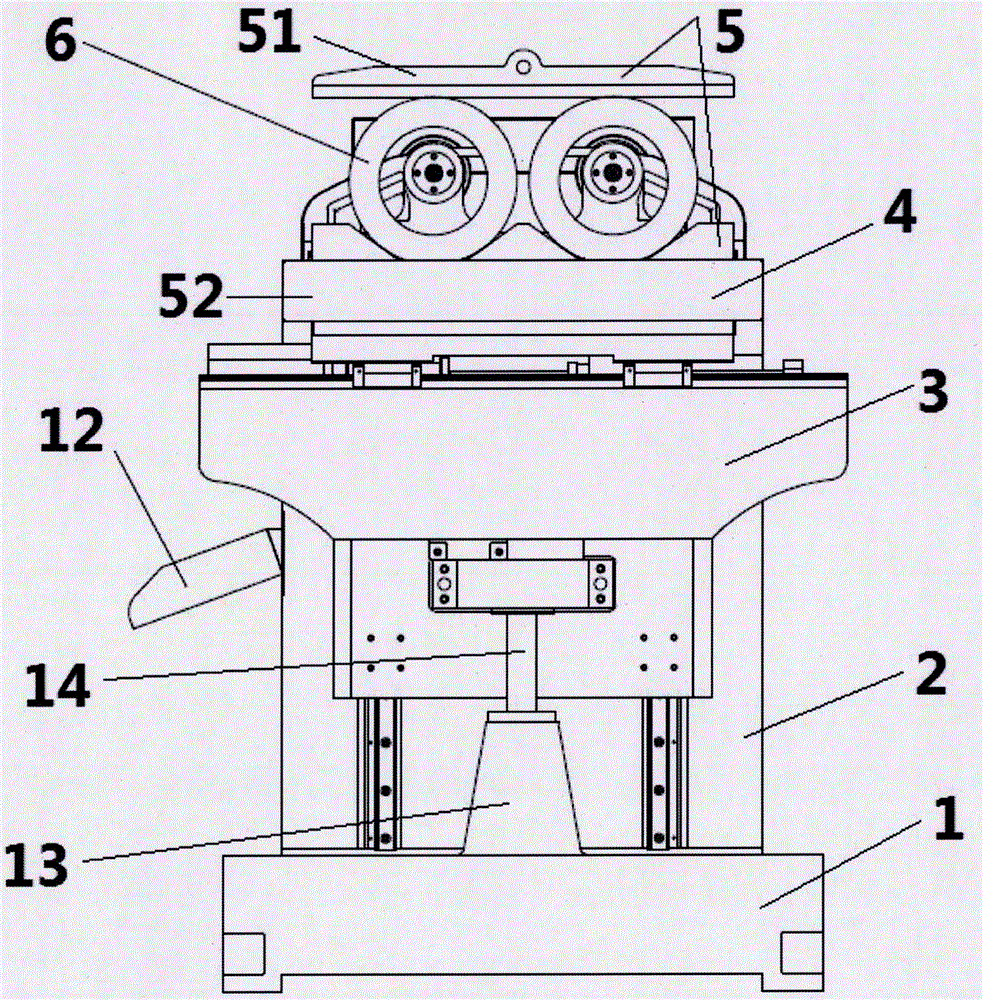

Double-end CNC (numerical control) deep hole drilling machine

A technology of deep hole drilling machine and bed, which is applied in the direction of boring/drilling, drilling/drilling equipment, maintenance and safety accessories, etc. It can solve the problem that the operator cannot find it immediately, the gun drilling tool is prone to bending, and the processing state Instability and other problems, to achieve the effect of wide application range, increase rigidity, and simplify structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Such as figure 1 and figure 2 As shown, the double-head CNC deep hole drilling machine of the present invention includes a workpiece moving module, a gun drill feed module, a bed 2 and a base 1, the bed 2 is fixedly arranged on the base 1, and the workpiece moving module includes a Y-axis lifting slide 3 , X-axis worktable 4 and workpiece fixture 5, Y-axis lifting slide 3 is movable and set on one side of bed 2, Y-axis lifting slide 3 and bed 2 are movably connected by guide rod and guide sliding sleeve , a hydraulic cylinder 13 is arranged below the Y-axis lifting slide table 3, the ejector rod 14 of the hydraulic cylinder 13 is fixedly connected with the bottom of the Y-axis lifting slide table 3, the hydraulic cylinder 13 is arranged on the base 1, and the Y-axis lifting slide table 3 The top surface is provided with an X-axis worktable guide rail perpendicular to the guide rail. The X-axis worktable 4 is movably set on the X-axis worktable guide rail. The workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com