Device and method for monitoring a workspace for laser material processing

A monitoring device, optical device technology, applied in the direction of measuring device, auxiliary device, laser welding equipment, etc., can solve the problems of not ensuring enough reliable monitoring, complex and expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

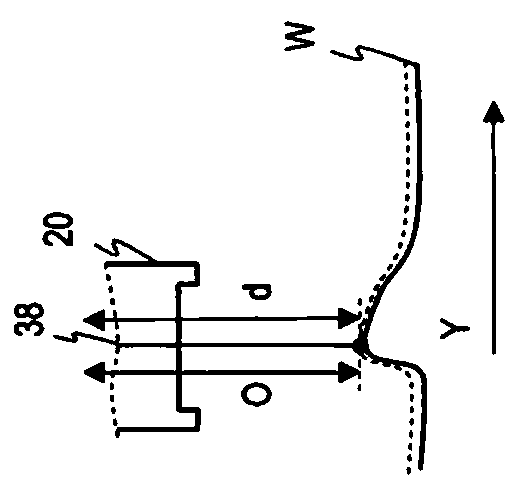

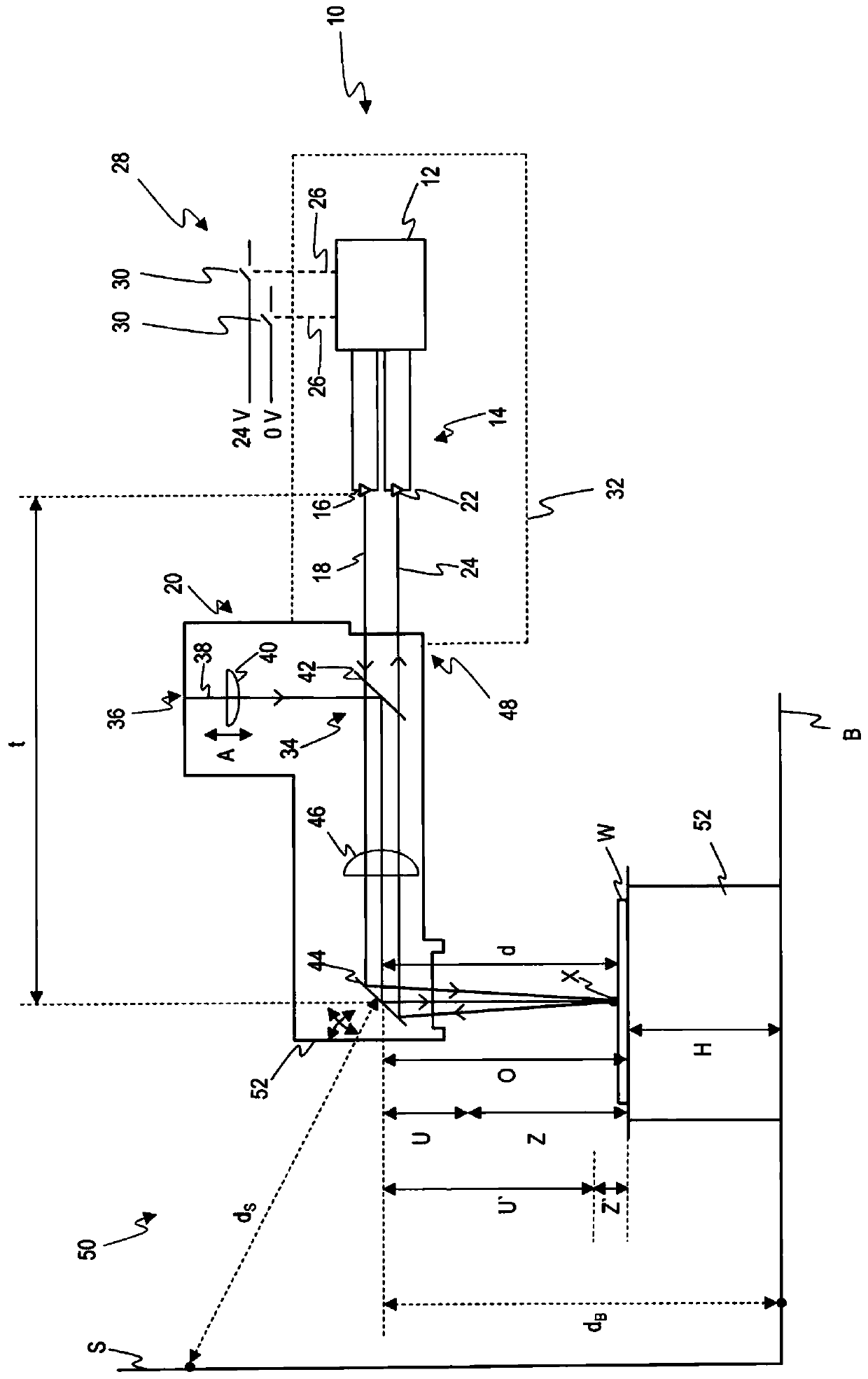

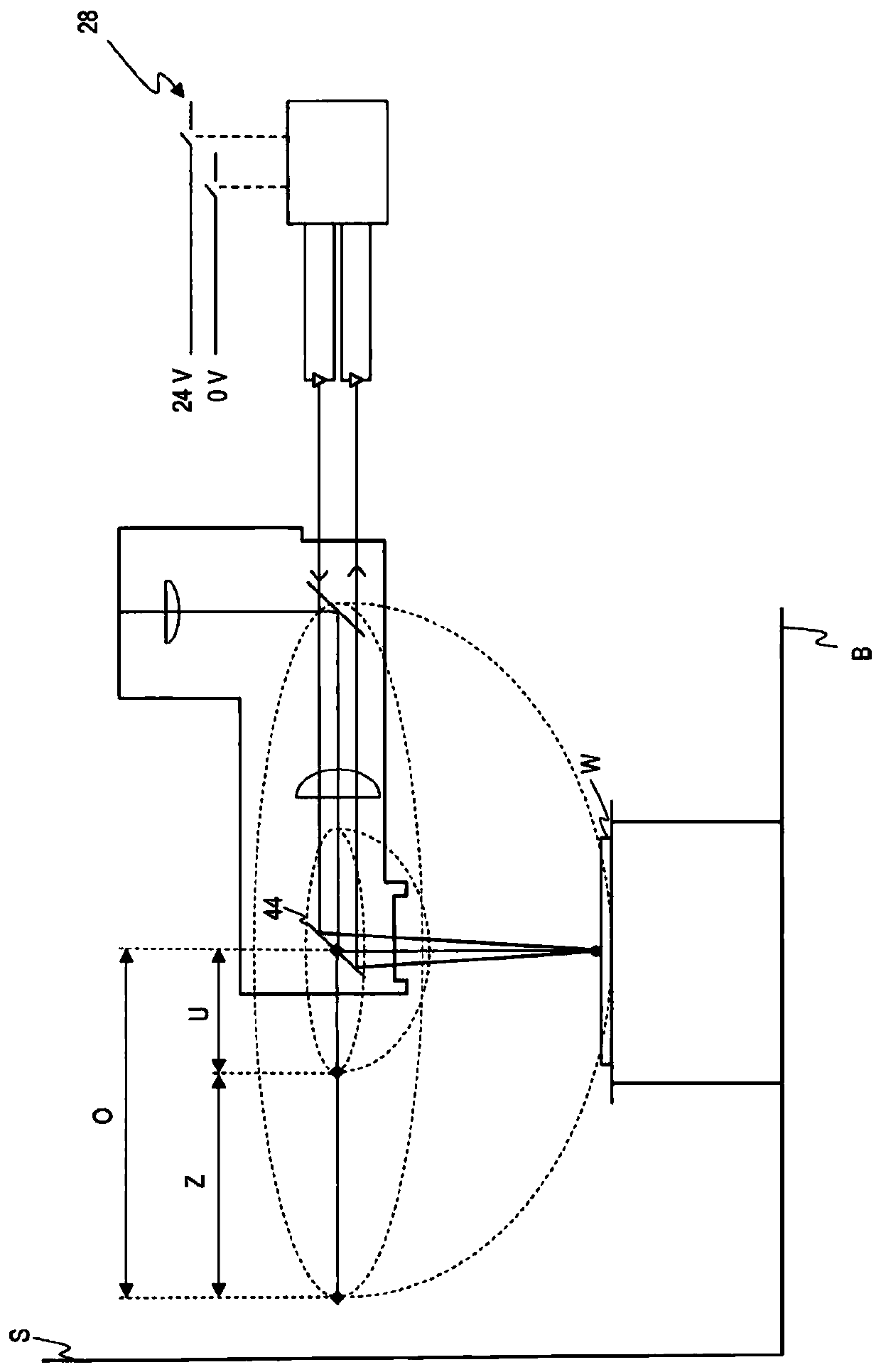

[0062] figure 1 A monitoring device according to the invention is shown and generally designated 10 . The monitoring device 10 includes an arithmetic unit 12 including a determination unit not shown separately. The computing unit 12 is connected to a measuring unit 14 , which in the present case is designed as an optical distance measuring unit in the form of a time-of-flight sensor device. In detail, the measuring unit 14 comprises a measuring beam source in the form of a laser diode 16 which emits measuring beam pulses 18 in the direction of the laser welding head 20 . Furthermore, the measuring unit 14 includes a recording unit in the form of a photodiode 22 , by means of which a measuring beam component 24 reflected by the environment can be detected.

[0063] It can also be seen that the computing unit 12 is connected to a power source 28 of the laser processing system, not shown separately, via a communication link 26 shown in dotted lines. More precisely, the computi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com