Car body assembly welding clamp

A technology for welding fixtures and car bodies, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low personnel safety, difficulty in ensuring production rhythm, and difficulty in operation, so as to improve production efficiency and improve Safety and production cycle time, the effect of reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

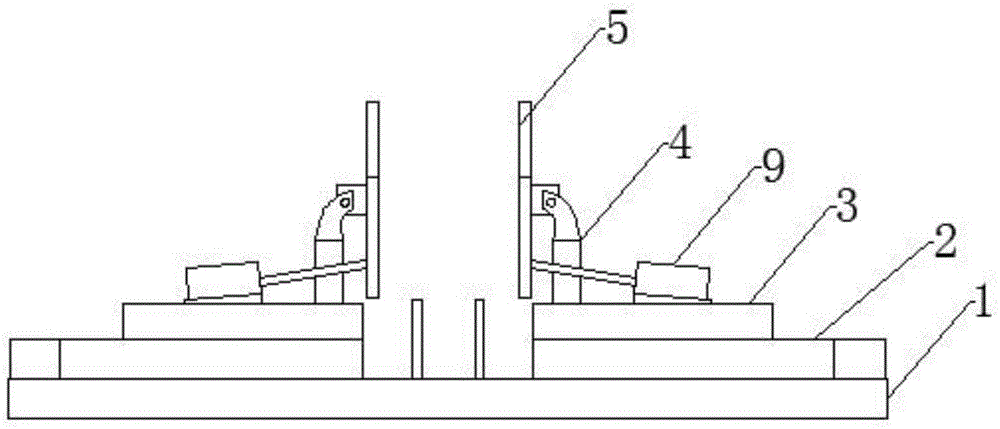

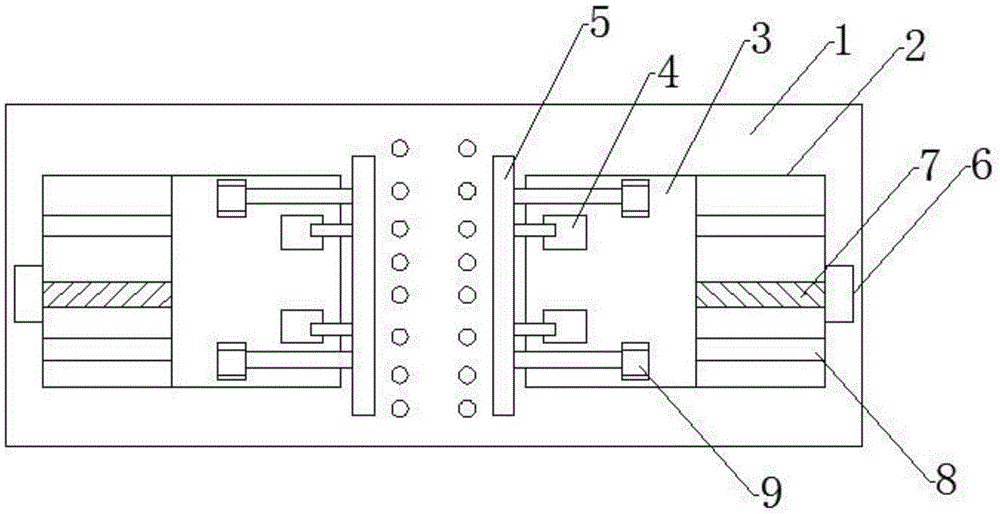

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0015] A welding fixture for automobile body assembly, comprising a base 1, two side clamping parts symmetrically set up on the base 1, the side clamping parts include a mounting seat 2, a guide seat 3, a hinge seat 4 and Clamp the bracket 5, the mounting seat (2) is provided with a screw rod (6), the two sides of the screw rod (6) are provided with a sliding rod (8), the sliding rod (8) and the screw rod (6) The extension direction is consistent with the length direction of the mounting seat (2), the guide seat (3) is sleeved on the sliding rod (8), the screw rod (6) and the bottom of the guide seat (3) are screwed together, One end of the screw rod (6) is connected with a driving motor (7) to drive the guide seat (3) to slide along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com