Cyclone meat cutter

A whirlwind and meat slicer technology, which is applied in metal processing and other fields, can solve the problems of complex meat slice thickness adjustment mechanism, limited meat cutting efficiency, high manufacturing cost and maintenance cost, and achieves convenient adjustment and setting of working data and improves meat cutting. Efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

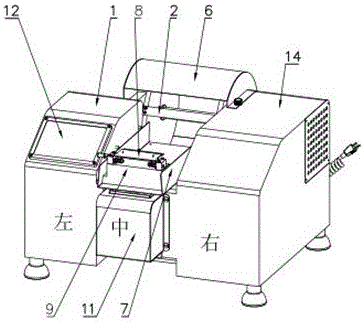

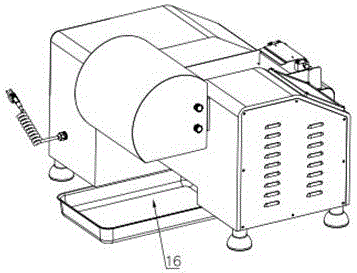

[0029] The present invention is a cyclone type meat cutting machine, which includes an electric control unit 12, a power part, a cutter head part 2, a meat pushing part; the power part is connected to the cutter head part 2; the meat pushing part is arranged on the cutter head part 2 Front lower part.

[0030] The specific structure of the cyclone meat slicer of the present invention and the function of each part of the structure are as follows:

Embodiment 2

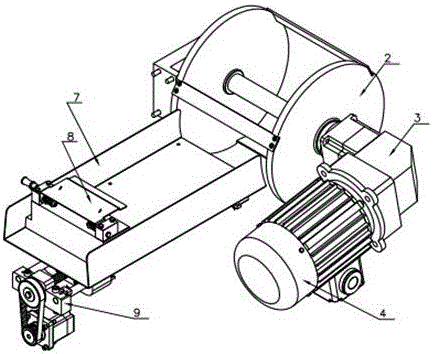

[0032] The power components include a motor 4 and a planetary reducer 3; the motor 4 is connected to the planetary reducer 3, and the planetary reducer 3 is connected to the cutter head part 2;

[0033] The power component is the power source of the cutter head component in the cyclone meat cutting machine of the present invention, and the electric-planetary reducer drives the cutter head to rotate for cutting action.

Embodiment 3

[0035] The structure of the cutter head part 2 is as follows:

[0036] The cutter head part 2 is a cylindrical cutter head part, which includes left and right cutter heads 2.5, 2.1, a central shaft 2.3, a cutter head support seat 2.9, and a number of blades 2.2; the center 2.3 shaft is aligned with the center holes of the left and right cutter heads 2.5, 2.1 Cooperate, the left and right ends of several blades 2.2 are fixed on the circumferential surfaces of the left and right cutterheads 2.5, 2.1; the leftmost end of the central shaft 2.3 is assembled in the bearing 2.8 of the inner hole of the cutterhead support seat 2.9, the output of the planetary reducer 3 The shaft is assembled in the blind hole at the right flange end of the central shaft 2.3.

[0037] Among them, the left end of the central shaft 2.3 is connected to the left cutter head 2.5 by a flat key 2.6, and its right end is fixed on the right cutter head 2.1 by a screw 2.9. The left and right sides of the left cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com