Method for sulfate process titanium dioxide salt treatment through wet process phosphoric acid

A wet-process phosphoric acid and salt treatment technology, applied in chemical instruments and methods, titanium dioxide, titanium compounds, etc., can solve the problems of large product content, inability to produce titanium dioxide, and inability to directly use sulfuric acid method for titanium dioxide salt treatment process, etc. The effect of broadening the application and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

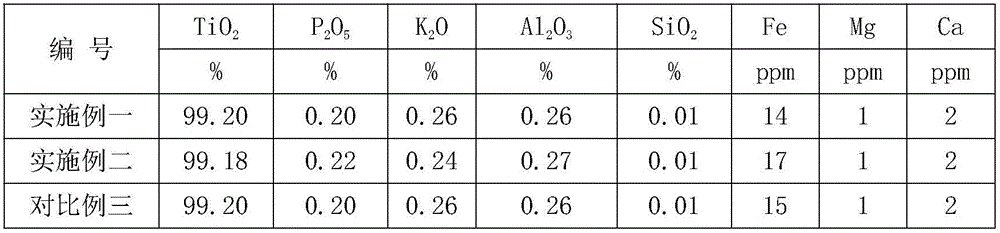

Examples

Embodiment 1

[0032] 1, get the thick metatitanic acid slurry 1000ml that obtains by hydrolyzing titanyl sulfate solution (wherein TiO 2 =160g / l), add 1.6ml of wet-process phosphoric acid (wherein P 2 o 5 =200g / l), mixed slurry is carried out solid-liquid separation after mixing evenly, obtains a filter cake;

[0033] 2. Wash the filter cake once with water to remove the iron ions in it, and measure the Fe / TiO in the filter cake base after washing 2 =2428ppm, obtain a wash metatitanic acid cake;

[0034] 3. After washing the metatitanic acid cake, add water and beat until TiO 2 =300g / l, then add 98 acid, trivalent titanium to the slurry, and add calcined seeds to adjust the H in the mixed slurry 2 SO 4 = 40g / l, Ti 3+ = 0.1g / l, calcined seed crystal = 2.5%, then keep the temperature at 60°C for 60 minutes, and then perform solid-liquid separation on the bleached slurry to obtain a secondary filter cake;

[0035] 4. Wash the filter cake twice with water to remove the iron ions in it, a...

Embodiment 2

[0038] 1, get the thick metatitanic acid slurry 1000ml that obtains by hydrolyzing titanyl sulfate solution (wherein TiO 2 =160g / l), add 2.0ml wet-process phosphoric acid (wherein P 2o 5 =200g / l), mixed slurry is carried out solid-liquid separation after mixing evenly, obtains a filter cake;

[0039] 2. Wash the filter cake once with water to remove the iron ions in it, and measure the Fe / TiO in the filter cake base after washing 2 =2943ppm, obtain a wash metatitanic acid cake;

[0040] 3. After washing the metatitanic acid cake, add water and beat until TiO 2 =346g / l, then add 98 acid, trivalent titanium to the slurry, and add calcined seeds to adjust the H in the mixed slurry 2 SO 4 =42g / l, Ti 3+ = 0.24g / l, calcined seed crystal = 1.5%, then keep the temperature at 60°C for 60min, and then perform solid-liquid separation on the bleached slurry to obtain a secondary filter cake;

[0041] 4. Wash the filter cake twice with water to remove the iron ions in it, and measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com