A nanofiltration salt separation process confirmation method based on isoelectric point identification

An isoelectric point and process technology, applied in chemical instruments and methods, membranes, reverse osmosis, etc., can solve the problems of unsuitable process requirements, low efficiency, complex process formulation process, etc., to improve the success rate and work efficiency, accurate definite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

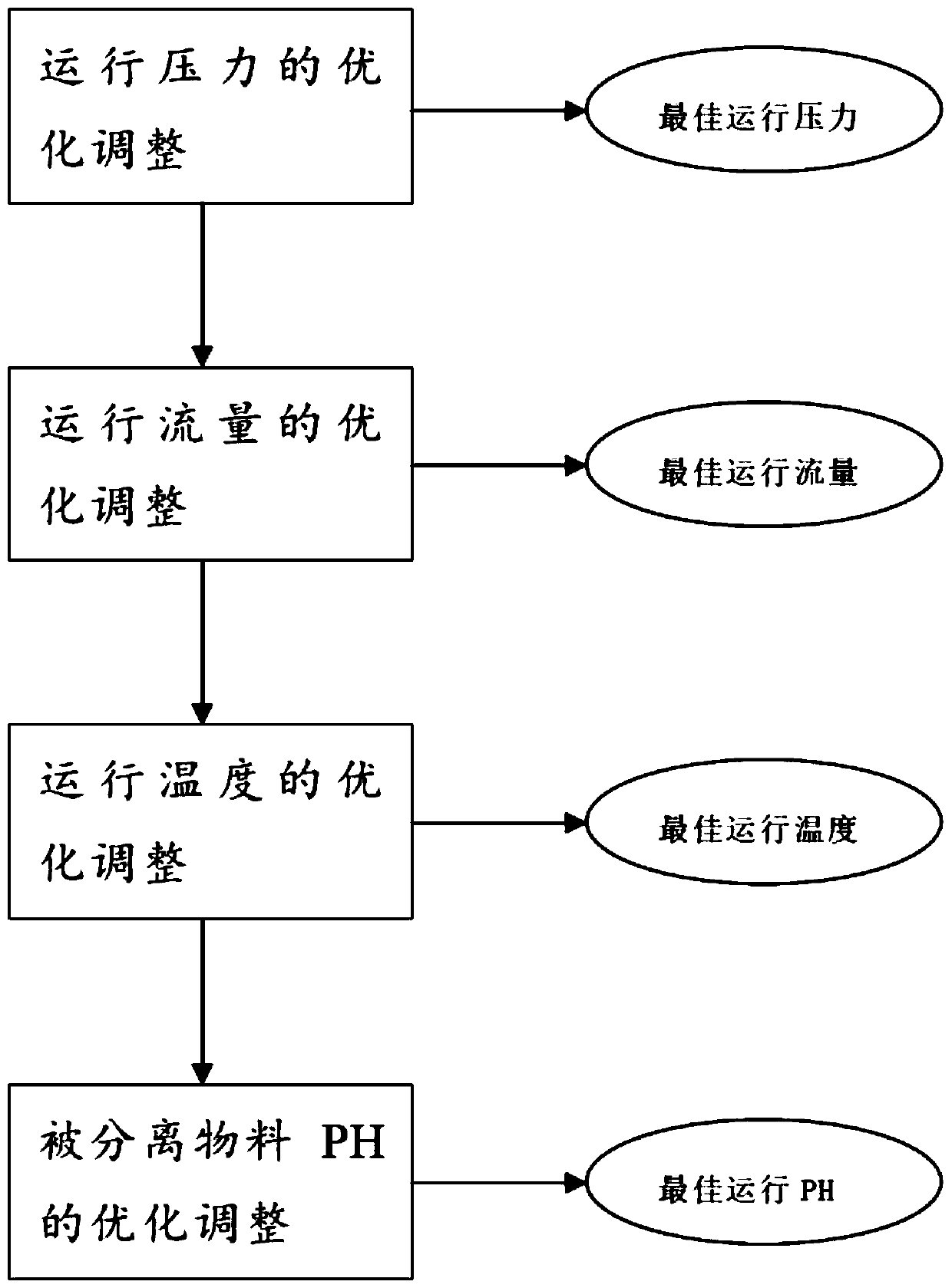

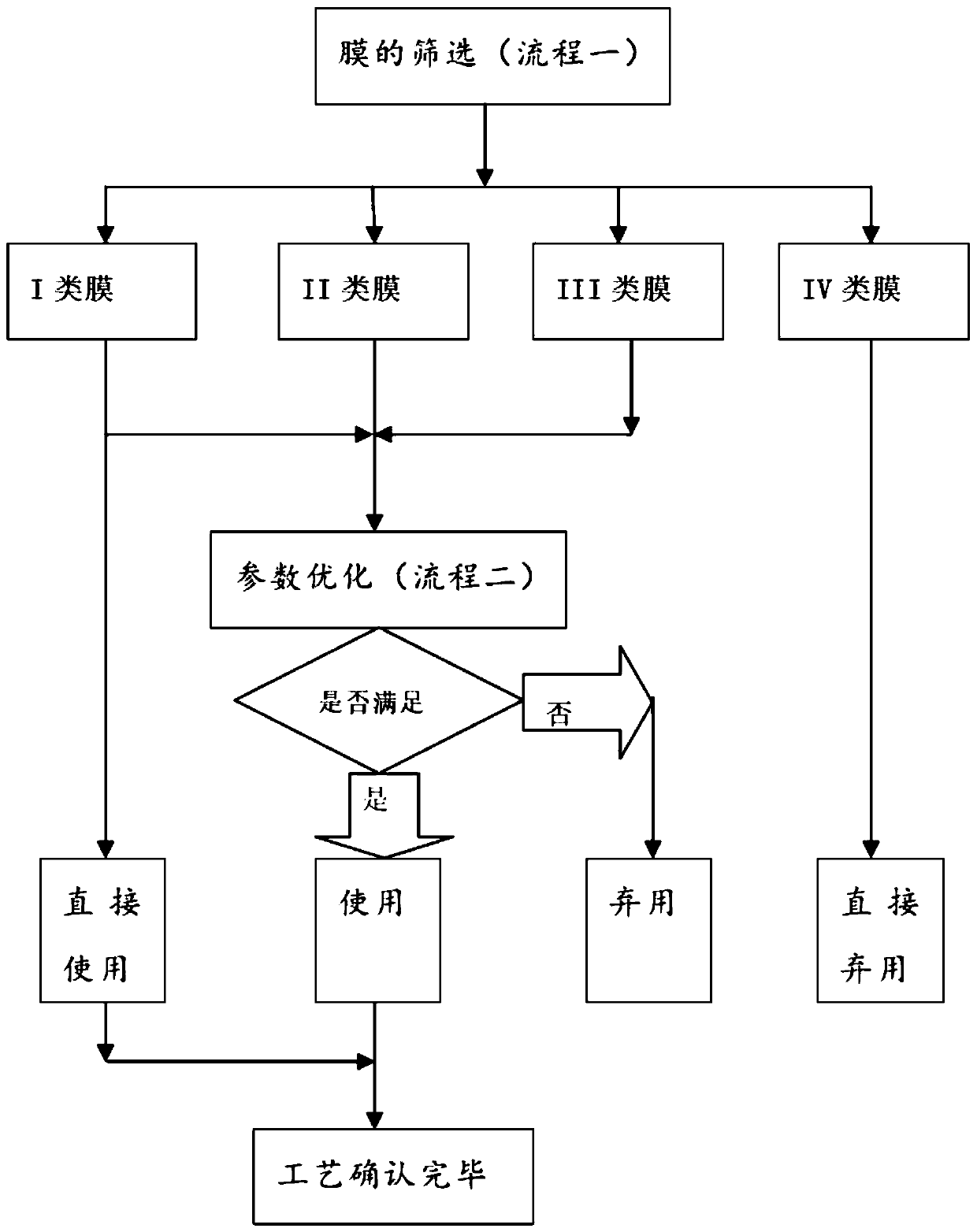

Method used

Image

Examples

Embodiment 1

[0049] Nanofiltration Membrane Separation of Na 2 SO 4 And the process confirmation method of the mixed solution of NaCl:

[0050] For membrane screening, select a nanofiltration membrane roll-type NF2540 component. After testing, the initial separation coefficient of the membrane for the two components is about 2.5, which can meet the process requirements and can be used directly. Reach above 15Bar, the operating flow is 1m 3 About / h, the operating temperature is 30-35 degrees Celsius, and when the pH is adjusted to 5 with HCl, the initial separation coefficient increases to 2.8, which is finally confirmed as the optimal separation process scheme.

Embodiment 2

[0052] Separation of Mg by Nanofiltration Membrane 2+ and Li + The process confirmation method of the mixed solution:

[0053] For membrane screening, select a nanofiltration membrane roll-type NF2540 module. After testing, the initial separation coefficient of the membrane for the two components is about 1.3, and in the relative isoelectric point detection, the rejection rate of 2000ppmNaCl is 60%. You can try to pass various processes Parameter optimization, increase the initial separation coefficient, found that when the operating pressure reaches above 15Bar, the operating flow rate is 1m 3 / h, temperature 25-35 degrees Celsius, HCl to adjust the pH to about 4, the initial separation coefficient increased to 1.9, and finally confirmed as the optimal separation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com