A method of processing glass products

A processing method and technology of glass products, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems affecting the quality of glass products, difficult demoulding, roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

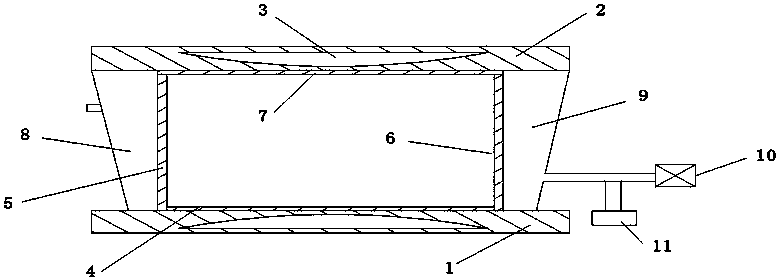

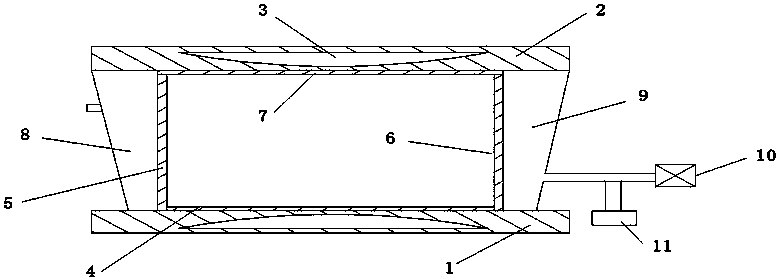

Image

Examples

Embodiment 1

[0019] A method for processing glass products, comprising the steps of:

[0020] (1) Ingredients: Mix 70 parts of quartz sand, 8 parts of limestone, 12 parts of feldspar, 6 parts of soda ash, and 1 part of boric acid as glass raw materials.

[0021] (2) Melting: Glass raw materials are melted in a continuous kiln at a melting temperature of 1300°C to form a uniform molten glass without bubbles. The melting area of the continuous kiln is 140m 2 , large capacity, less heat loss, thermal efficiency is significantly higher than that of ordinary kilns, which can homogenize the temperature of the molten glass. Since the temperature of the molten glass near the bottom of the continuous kiln is low and it is in a stagnant state, the molten glass in the continuous kiln The total capacity of the liquid is greater than the amount of working glass, and the feeding amount and molding amount of continuous operation are kept in balance.

[0022] (3) Molding: Before pouring molten glass, ...

Embodiment 2

[0025] A method for processing glass products, comprising the steps of:

[0026] (1) Ingredients: Mix 75 parts of quartz sand, 9 parts of limestone, 13 parts of feldspar, 7 parts of soda ash, and 1.5 parts of boric acid as glass raw materials.

[0027] (2) Melting: Glass raw materials are melted in a continuous kiln at a melting temperature of 1400°C to form a uniform glass liquid without bubbles. The melting area of the continuous kiln pool is 145m 2 , large capacity, less heat loss, thermal efficiency is significantly higher than that of ordinary kilns, which can homogenize the temperature of the molten glass. Since the temperature of the molten glass near the bottom of the continuous kiln is low and it is in a stagnant state, the total amount of molten glass in the continuous kiln is The capacity is greater than the amount of working glass, and the feeding amount and molding amount of continuous operation are in balance.

[0028] (3) Molding: Before pouring molten glass...

Embodiment 3

[0031] A method for processing glass products, comprising the steps of:

[0032] (1) Ingredients: Mix 80 parts of quartz sand, 10 parts of limestone, 14 parts of feldspar, 8 parts of soda ash and 2 parts of boric acid as glass raw materials.

[0033] (2) Melting: Glass raw materials are melted in a continuous kiln at a melting temperature of 1500°C to form a uniform glass liquid without bubbles. The melting area of the continuous kiln pool is 150m 2 , large capacity, less heat loss, thermal efficiency is significantly higher than that of ordinary kilns, which can homogenize the temperature of the molten glass. Since the temperature of the molten glass near the bottom of the continuous kiln is low and it is in a stagnant state, the total amount of molten glass in the continuous kiln is The capacity is greater than the amount of working glass, and the feeding amount and molding amount of continuous operation are in balance.

[0034](3) Forming: before pouring the molten glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com