Glass composition, alkali silicate glass, and preparation method and application thereof

A technology of alkali silicate and composition, which is applied in the field of glass composition to achieve good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

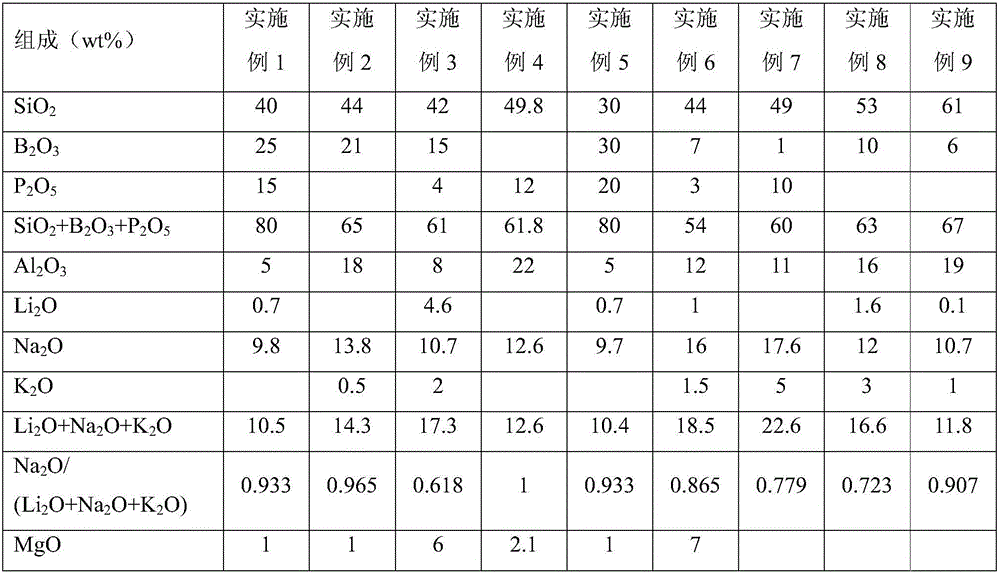

Embodiment 1-9

[0096]Weigh each component according to the glass composition shown in Table 1, mix well, pour the mixture into a platinum crucible, then heat in a resistance furnace at 1430°C for 4 hours, and stir with a platinum rod to remove air bubbles. Pour the molten glass into a stainless steel cast iron mold to form a specified block glass product, then anneal the glass product in an annealing furnace for 2 hours, turn off the power and cool down to 25°C with the furnace. Cut, grind and polish the glass products, clean the surface of the polished 80*80*1mm glass products with deionized water, put them into molten NaNO at 450°C after preheating in the preheating furnace 3 and KNO 3 (NaNO 3 and KNO 3 The molar ratio is 1.2:1) and treated for 10h, annealed and cooled, cleaned with deionized water, dried, and then preheated in a preheating furnace and placed in molten NaNO at 430°C 3 and KNO 3 Mixture (NaNO 3 and KNO 3 The molar ratio is 0.005:1) and treated for 0.5h, annealed and c...

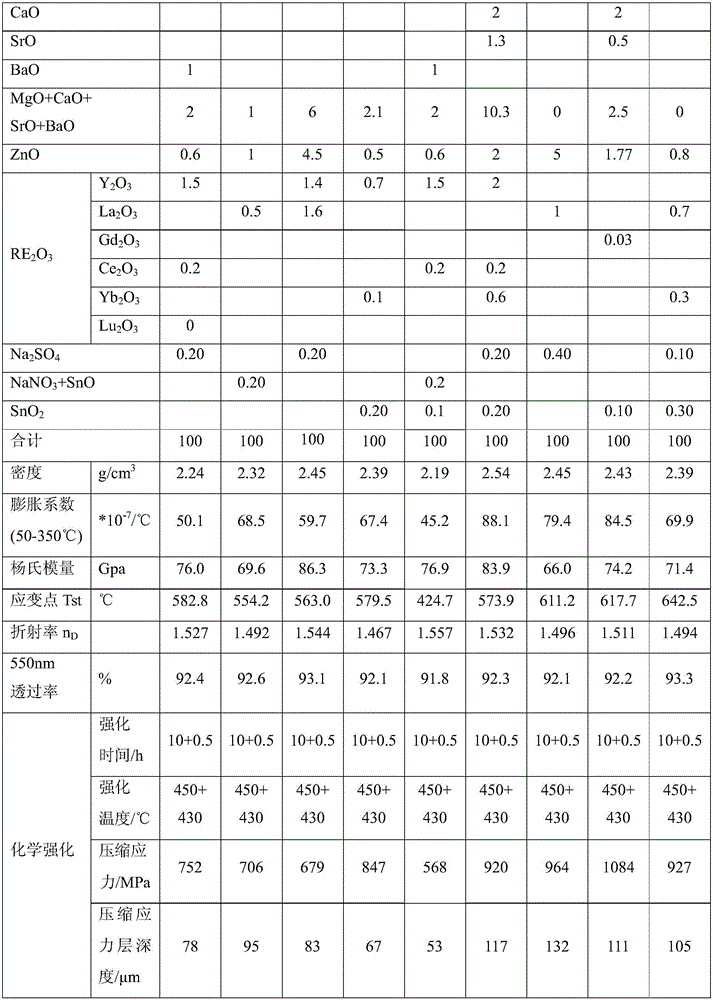

Embodiment 10-15、 comparative example 1-3

[0102] According to the method of Example 1, the difference is that the composition of the mixture (corresponding to the glass composition) and the performance measurement results of the obtained product are shown in Table 2.

[0103] Table 2

[0104]

[0105]

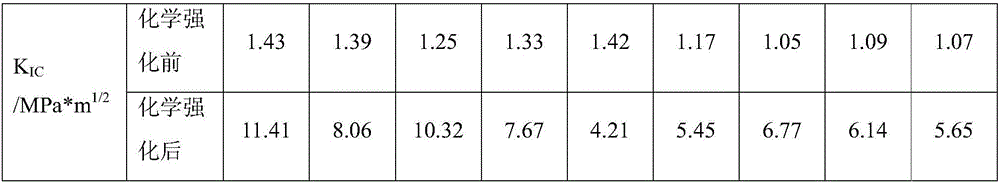

Embodiment 16-17、 comparative example 5-8

[0109] The glass products obtained by polishing Example 16 (the corresponding glass composition is the same as Example 2), Example 17 (the corresponding glass composition is the same as Example 9), and Comparative Examples 5-8 (the corresponding glass composition is the same as Comparative Examples 1-4 respectively) Perform secondary melting and thinning treatment to obtain a glass product of 80*50*0.08mm. The surface of the glass product is cleaned with deionized water and preheated in a preheating furnace, and then put into molten KNO at 410°C 3 After annealing and cooling for 2.5 hours, take it out and cool it to 25°C, wash it with deionized water and dry it to obtain a finished glass product for use. Various properties of each glass product were measured respectively, and the results are shown in Table 3 (wherein, the thickness of the glass obtained in Comparative Example 8 was 0.08 mm, and a chemical strengthening treatment was performed).

[0110] table 3

[0111]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com